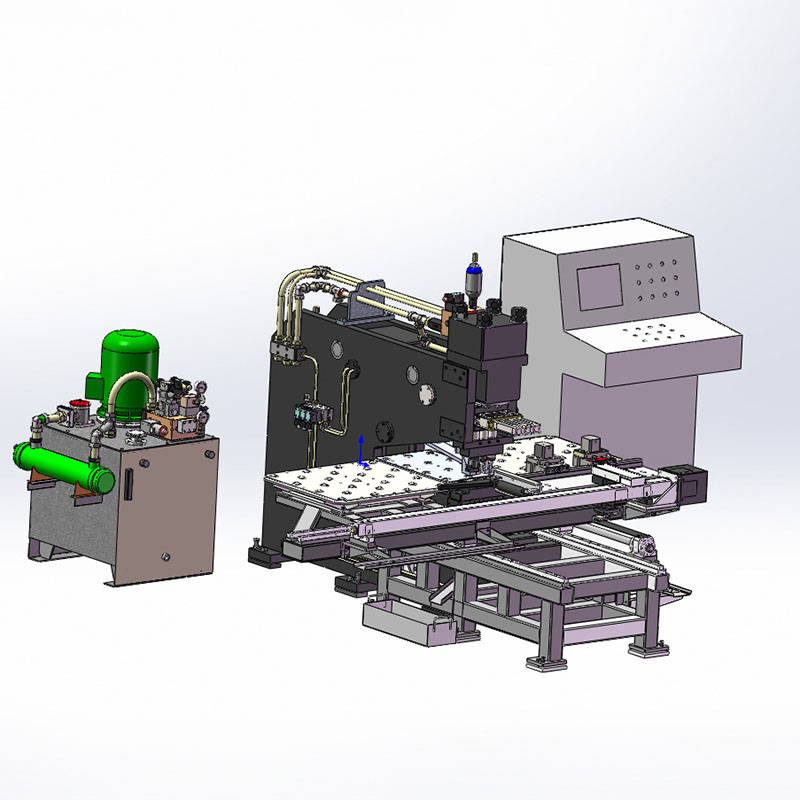

Best quality Angle Shear Machine - BHD1005A/3 FINCM CNC three side high Speed Drilling Machine For H Beam – FIN CNC

Best quality Angle Shear Machine - BHD1005A/3 FINCM CNC three side high Speed Drilling Machine For H Beam – FIN CNC Detail:

Product Parameter

|

NO. |

Item name |

Parameters |

|

|

1 |

Machining range |

H-beam |

Section height H: 150-1000mm Flange width B: 75 ~ 500mm |

|

Maximum thickness of material |

60mm |

||

|

2 |

Drilling power box |

Quantity |

3 |

|

Max. drilling diameter |

Cemented carbide ¢ 30mm High speed steel ¢ 40mm |

||

|

Spindle taper hole |

BT40 |

||

|

Spindle motor power |

3×11KW |

||

|

Spindle speed (stepless speed regulation) |

0~2000r/min |

||

|

3 |

CNC axis |

Quantity |

7 |

|

Servo motor power of fixed side, moving side and middle side feed shaft |

3×2KW |

||

|

Fixed side, moving side, middle side, moving side positioning axis servo motor power |

3×1.5KW |

||

|

Moving speed of three positioning CNC axes |

0~10m/min |

||

|

Moving speed of three feed CNC axes |

0~5m/min |

||

|

Width detection stroke |

900mm |

||

|

Web detection stroke |

290mm |

||

|

4 |

Feeding trolley |

Feeding trolley servo motor power |

5 KW |

|

Maximum feeding speed |

20m/min |

||

|

Maximum feeding weight |

8T |

||

|

5 |

Spray cooling system |

Number of nozzles |

1 |

|

6 |

Compressed air pressure |

0.5Mpa |

|

|

7 |

Cooling mode |

Internal cooling + external cooling |

|

|

8 |

Dimension of main machine (L x W x H) |

About 5.6×1.6×3.3m |

|

|

9 |

Machine weight |

About 7000Kg |

|

Details and advantages

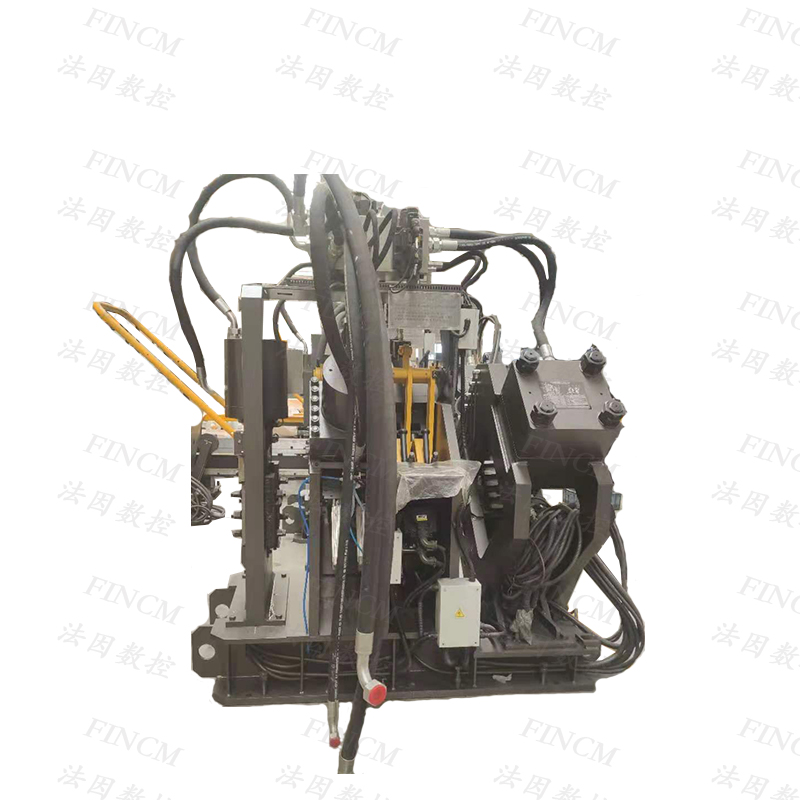

1 There are six CNC axes on the three sliding tables, including three feed CNC axes and three positioning CNC axes. Each CNC axis is guided by precision linear rolling guide and driven by AC servo motor and ball screw, which ensures its positioning accuracy.

2 Each spindle box can be drilled separately or at the same time.

3 Equipped with BT40 taper hole, it is convenient for tool changing, and can be used to clamp twist drill and cemented carbide drill. The performance of drilling and tool changing is stable, and it has a wide range of applications. The speed can be continuously variable in a large range to meet a variety of speed requirements。

4 The material is fixed by hydraulic clamping. There are five hydraulic cylinders for horizontal clamping and vertical clamping respectively.

5 In order to meet the processing of multiple hole diameters, the machine is equipped with three in-line tool magazine, each unit is equipped with a tool magazine, and each tool magazine is equipped with four tool positions.

6 The machine is equipped with material width detection and web height detection device, which can effectively compensate the deformation of the material and ensure the machining accuracy;

7 The machine adopts the trolley feeding, and the CNC clamp feeding mechanism.

8 Each spindle box is equipped with its own external cooling nozzle and internal cooling joint, which can be selected according to the needs of drilling.

key outsourced components

|

NO. |

Name |

Brand |

Country |

|

1 |

Spindle |

Kenturn |

Taiwan, China |

|

2 |

Linear rolling guide rail pair |

HIWIN/CSK |

Taiwan, China |

|

3 |

Hydraulic pump |

Justmark |

Taiwan, China |

|

4 |

Solenoid hydraulic valve |

ATOS/Yuken |

Italy / Japan |

|

5 |

Servo motor |

Siemens / MITSUBISHI |

Germany / Japan |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for Best quality Angle Shear Machine - BHD1005A/3 FINCM CNC three side high Speed Drilling Machine For H Beam – FIN CNC , The product will supply to all over the world, such as: Russia, Latvia, Bolivia, Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!