China CNC High-Efficiency H Beam Band Saw Machine

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for China CNC High-Efficiency H Beam Band Saw Machine, We have ISO 9001 Certification and qualified this product .over 16 years experiences in manufacturing and designing, so our products featured with best quality and competitive price. Welcome cooperation with us!

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Band Saw, China CNC Machine, “Make the women more attractive “is our sales philosophy. “Being customers’ trusted and preferred brand supplier” is the goal of our company. We have been strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

Product Parameters

| NO. | Item | Parameter | ||||

| DJ500 | DJ700 | DJ1000 | DJ1250 | |||

| 1 | Dimension of H-beam sawing (without turning angle) | 100×75~500×400 mm | 150×75~700×400 mm | 200×75~1000×500 mm | 200×75~1250×600mm | |

| 2 | Sawing blade dimension | T:1.3mm W:41mm | T:1.6mm W:54mm | T:1.6mm W:67mm | ||

| 3 | Motor power | Main motor | 5.5 kW | 11 kW | 15 kW | |

| Hydraulic pump | 2.2kW | 5.5kW | 5.5kW | |||

| 4 | Linear speed of saw blade | 20~80 m/min | 20~100 m/min | |||

| 5 | Cutting feed rate | program control | ||||

| 6 | cutting angle | 0°~45° | ||||

| 7 | Table height | About 800 mm | ||||

| 8 | Main clamping hydraulic motor | 100ml/r | ||||

| 9 | Front clamping hydraulic motor | 100ml/r | ||||

| 10 | Overall dimension of main engine(L * w * h) | About2050x2300x2700mm | About3750x2300x2600mm |

About 4050x2300x2700mm | About 2200x4400x2800 mm | |

| 11 | Main Machine weight | About 2500kg | About 6000kg | About 8800kg | About 10t | |

Details and advantages

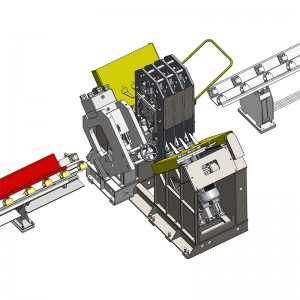

1. The machine is mainly composed of CNC feeding carriage, main machine, hydraulic system, electrical system and pneumatic system.

2. The sawing frame is welded by square steel pipe and steel plate, which makes the strength and accuracy of the saw frame more stable.

3. The saw frame adopts hydraulic servo proportional valve and encoder, which can realize digital feeding.

4. The machine has the main motor current detection function, when the motor overload operation, the cutting feed speed will automatically reduce, which greatly reduces the probability of the saw blade being “clamped”

5. The rotary table adopts frame structure, with good rigidity, strong stability and smooth sawing section.

6. The band saw blade adopts hydraulic tension, which can maintain good tension force in rapid movement, extending the service life of the sawing blade.

7. Sawdust automatic cleaning system is equipped with a power rotary brush on the saw blade frame to automatically clean the iron chips that may stick to the saw blade after cutting.

8. The machine has the function of turning 0°~45°Function: the beam material does not move but the whole machine rotates, then 0°~45°any angle between them can be cut.

9. The CNC feeding trolley device is driven by the gear rack after the servo motor decelerates by the reducer, so the positioning is accurate.

Key Outsourced Components List

| NO. | Name | Brand | Country |

| 1 | Linear guide rail | HIWIN/CSK | Taiwan, China |

| 2 | Hydraulic motor | Justmark | Taiwan, China |

| 3 | Magnescale | SIKO | Germany |

| 4 | Hydraulic pump | JUSTMARK | Taiwan, China |

| 5 | Electromagnetic hydraulic valve | ATOS/YUKEN | Italy / Japan |

| 6 | Proportional valve | ATOS | Italy |

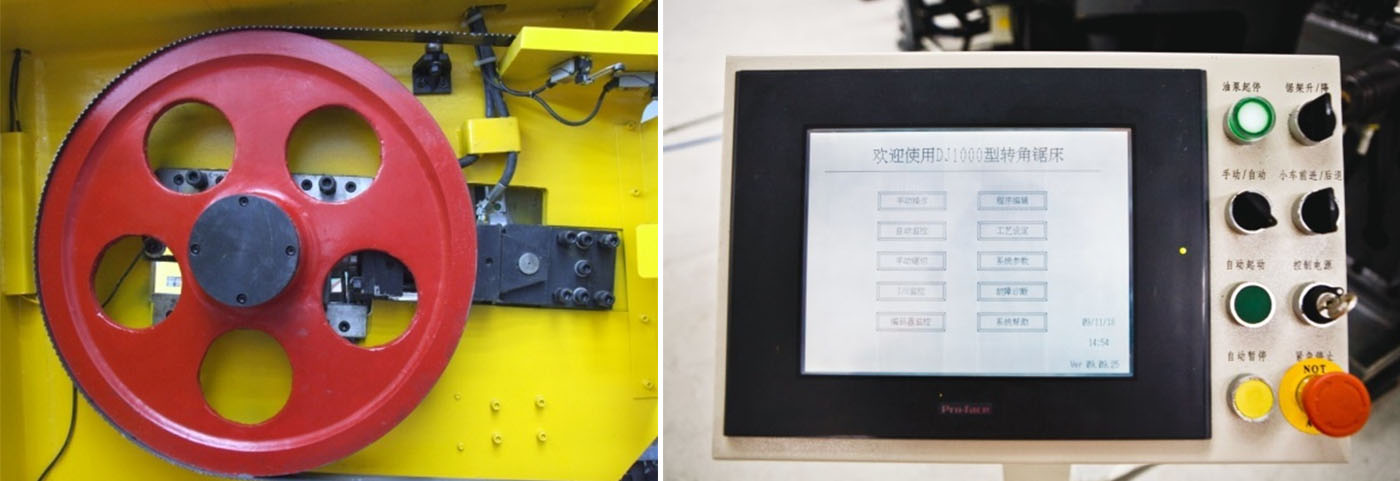

| 7 | Saw blade | LENOX /WIKUS | USA / Germany |

| 8 | Frequency converter | INVT/INOVANCE | China |

| 9 | PLC | Mitsubishi | Japan |

| 10 | Touch screen | Panel | Taiwan, China |

| 11 | Servo motor | PANASONIC | Japan |

| 12 | Servo driver | PANASONIC | Japan |

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in processing industry for China CNC High-Efficiency H Beam Band Saw Machine, We have ISO 9001 Certification and qualified this product .over 23 years experiences in manufacturing and designing, so our products featured with best quality and competitive price. Welcome cooperation with us!

China CNC Machine, Band Saw, “Quality Is the First”is our sales philosophy. “Being customers’ trusted and preferred brand supplier” is the goal of our company. We have been strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability