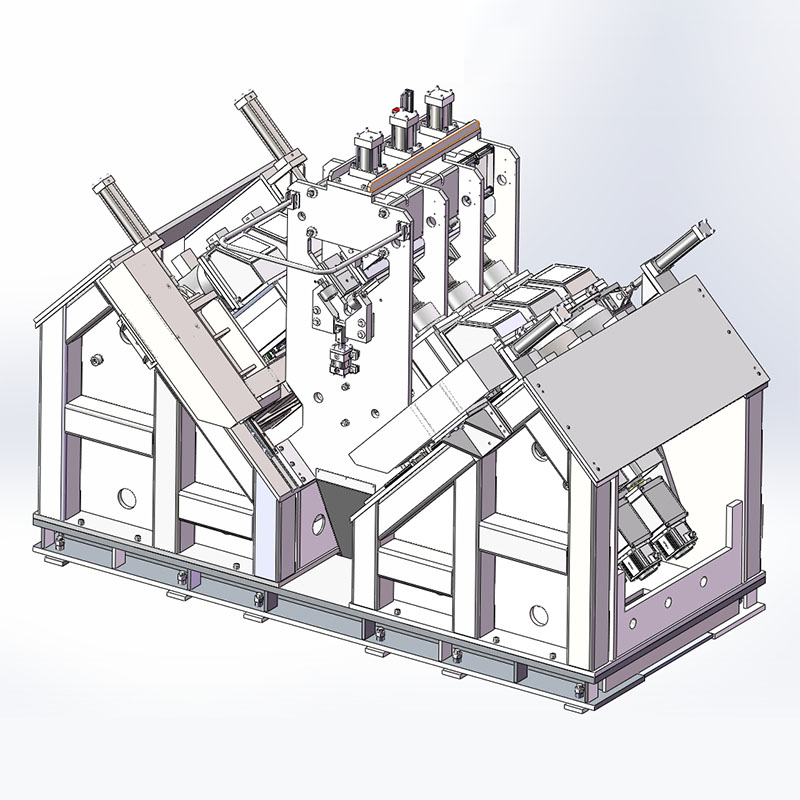

Europe style for Punching CNC Machine - PP123 Automatic CNC Hydraulic Punching Machine For Plates – FIN CNC

Europe style for Punching CNC Machine - PP123 Automatic CNC Hydraulic Punching Machine For Plates – FIN CNC Detail:

Product Parameters

|

NO. |

Item name |

Parameter |

|

1 |

Punching force |

1200KN |

|

2 |

Max process dimension |

1500×775mm |

|

3 |

Plate thickness |

5~25mm |

|

4 |

Number of punch and mark modulus |

3 |

|

5 |

Max punching diameter |

φ30mm For Q235 steel σb≤420MPa φ30×25mm (diameter* thickness) For Q420 steel σb≤680MPa φ30×25mm (diameter* thickness) |

|

6 |

Marking force |

1000KN |

|

7 |

Characters size: |

14×10mm |

|

8 |

Number of characters in a group |

16 |

|

9 |

Minimum hole margin |

25mm |

|

10 |

Number of clamp |

2 |

|

11 |

System pressure |

24 Mpa |

|

12 |

Low pressure |

5.5Mpa |

|

13 |

Air pressure |

0.5Mpa |

|

14 |

Hydraulic pump motor power |

22KW |

|

15 |

Number of CNC axis |

2 |

|

16 |

X、Y movable speed |

18 m/min |

|

17 |

X axis servo motor power |

2 KW |

|

18 |

Y axis servo motor power |

2KW |

|

19 |

Cooling method |

Water cooling |

|

20 |

Total power |

26KW |

|

21 |

Machine dimensions(L*W*H) |

3600*2800*1870mm |

|

22 |

Main machine weight |

7500kg |

Details and Advantages

1. The PP123 CNC hydraulic punching machine has a punching force of up to 1200KN. It has three die positions and can be equipped with three sets of punching dies, or only two sets of punching dies and a character box. The die is easy to replace and the print is clear.

2. The bed of the heavy-duty machine adopts a high-quality steel plate welded structure. After welding, the surface is painted,

Thereby, the surface quality and anti-rust ability of the steel plate are improved. The bed welding parts are heat-aged to minimize welding stress. As a result, the reliability and durability of the machine are improved.

3. Both X and Y axis use precision linear guide rails, which have large load, high precision and long service life of the guide rails.

And can maintain the high precision of the machine for a long time.

4. Use the combination of centralized lubrication and distributed lubrication to lubricate the machine, so that the machine can be lubricated. Always in good working order.

Key Outsourced components List

|

NO |

Name |

Brand |

Country |

|

1 |

AC servo motor |

Delta |

Taiwan(China) |

|

2 |

PLC |

Delta |

|

|

3 |

Electromagnetic unloading valve |

ATOS/YUKEN |

Italy / Taiwan(China) |

|

4 |

Relief valve |

ATOS/YUKEN |

|

|

5 |

Electromagnetic directional valve |

JUSTMARK |

Taiwan(China) |

|

6 |

Bus bar |

SMC/CKD |

Japan |

|

7 |

Air valve |

SMC/CKD |

|

|

8 |

Cylinder |

SMC/CKD |

|

|

9 |

Duplex |

AIRTAC |

Taiwan(China) |

|

10 |

Computer |

Lenovo |

China |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for Europe style for Punching CNC Machine - PP123 Automatic CNC Hydraulic Punching Machine For Plates – FIN CNC , The product will supply to all over the world, such as: Jakarta, European, Johor, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.