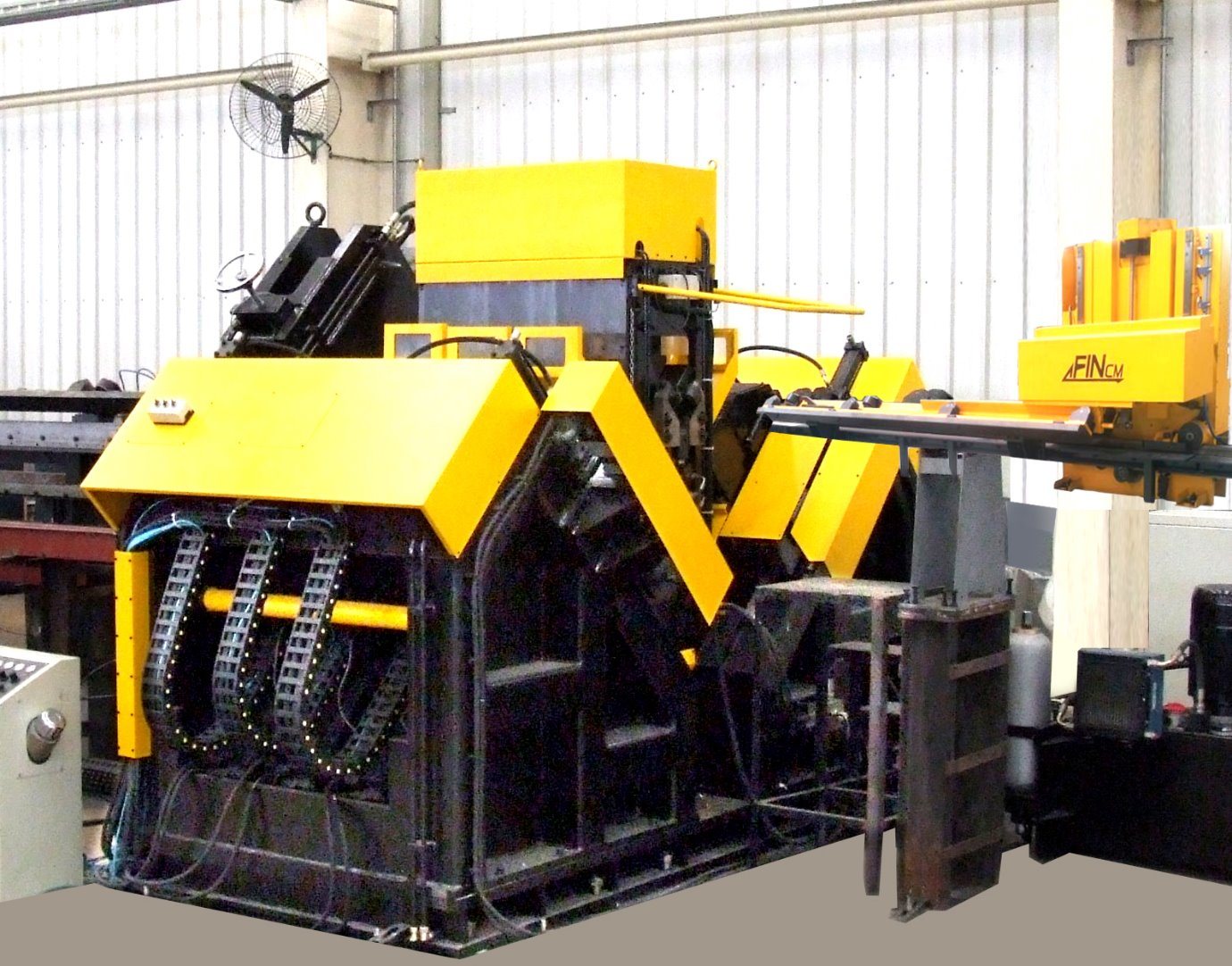

Factory Price Truck Beams – HD1715D-3 Drum horizontal three-spindle CNC drilling machine – FIN CNC

Factory Price Truck Beams – HD1715D-3 Drum horizontal three-spindle CNC drilling machine – FIN CNC Detail:

Product Parameters

| Parameter name | Item | Parameter value |

| Material size | Drum diameter range | Φ780-Φ1700mm |

| Drum length range | 2-15m | |

| Maximum thickness of cylinder wall | 50mm | |

| Maximum weight of material | 15Tons | |

| Maximum drilling diameter | Φ65mm | |

| Drilling spindlePower Head | Quantity | 3 |

| Spindle taper | No. 6 Morse | |

| Spindle speed | 80-200r/min | |

| Spindle stroke | 500mm | |

| Spindle feed speed(Hydraulic stepless) | 10-200mm/min | |

| Spindle motor power | 3×7.5kW | |

| Laser alignment device | Adjust the position of the hole group according to the position of the weld | |

| Material rotation speed | 0~2.8r/min | |

| Moving speed of carriage | 0~10m/min | |

| Height of chuck center to ground | About 1570mm | |

| Machine size (length x width x height) | About 22x5x2.5m | |

Details and advantages

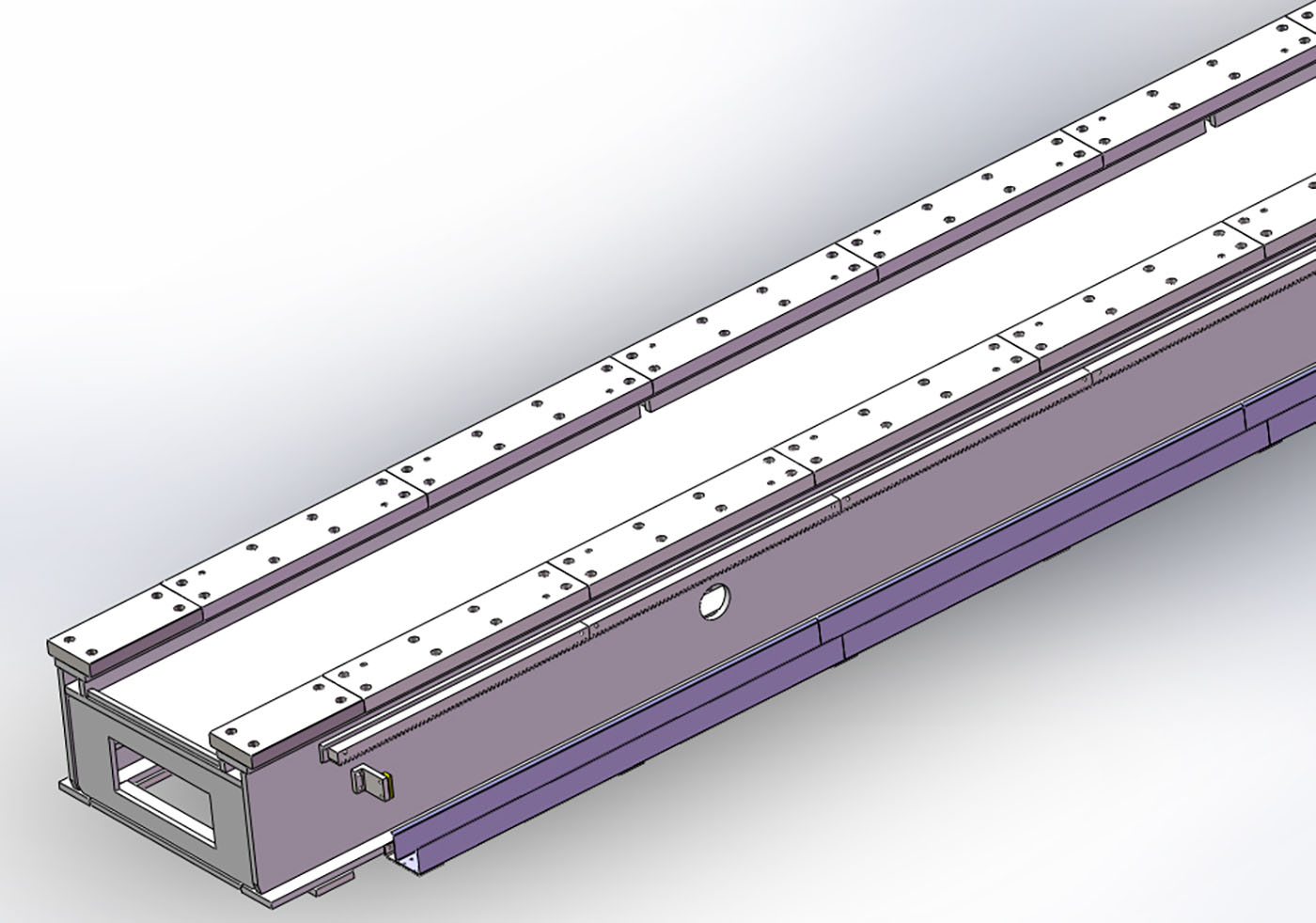

This machine is composed of bedⅠ, bedⅡrear support, chip removal and cooling, hydraulic systems, electrical systems, laser alignment devices and other components.

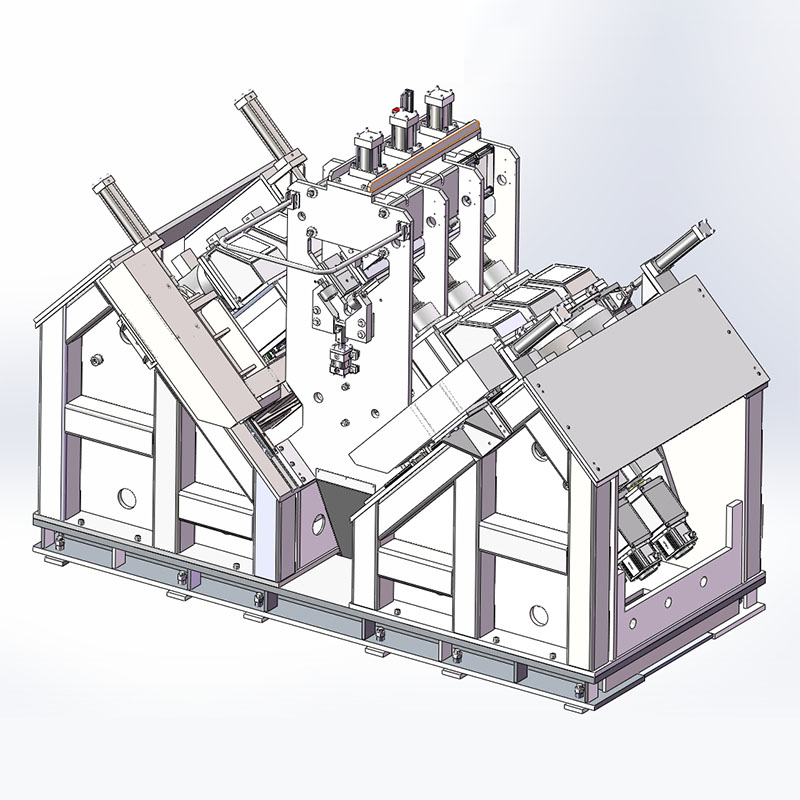

1. The No. 1 bed of this machine is mainly used to carry material. Both the head and foot of the bed are equipped with hydraulic three-jaw chucks, which can realize the automatic centering and clamping of the drum. The clamping diameter ranges from Φ780 to Φ1700mm.

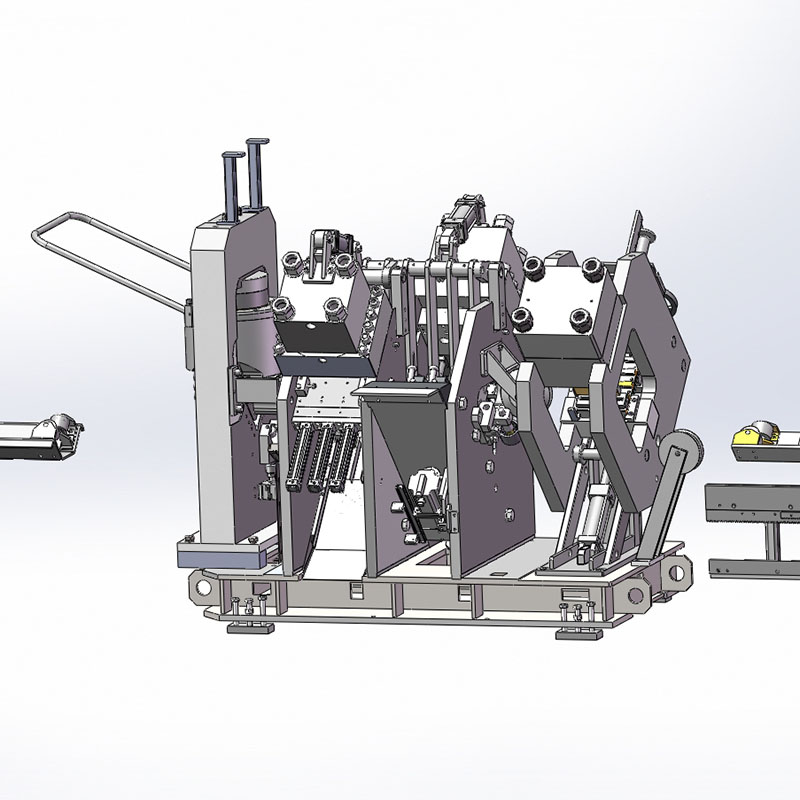

2. The second bed of this machine tool is mainly used to carry the longitudinal movement of the drilling power head. This machine has three independent drilling power heads, which respectively rely on longitudinal slides and hydraulic slides to move longitudinally on the No. Ⅱ bed.

3. The power head can realize the automatic control stroke through the hydraulic sliding table, and realize the automatic conversion of fast feeding forward, work feeding forward and fast backward. By adjusting the position of the non-contact switch block, it can also be realized that when the drill bit exits a certain distance at the end of the drilling, it automatically stops. The three power heads are independent and can realize automatic drilling, with high efficiency and good precision.

4. The head of the bed is fixed at one end of the bedⅠ, and the AC servo motor achieves numerical control indexing through the reducer and gear reduction. After the indexing is completed, the locking mechanism automatically hydraulically locks the brake disc installed on the spindle to ensure the stability and reliability of the spindle.

5. The front and rear supports of this machine can realize self-adaptive hydraulic jacking before and after the drum is clamped by the chuck, which improves the drilling rigidity of the drum.

6. This machine is equipped with a laser cross alignment device, which can be installed in the spindle taper hole of the first drilling power head.

7. The CAD drawings of the material can be directly input, the system automatically generates the processing program, and the three spindles automatically allocate the processing tasks of all holes.

8. This machine adopts Siemens numerical control system and has four numerical control axes: the rotation of the material and the longitudinal movement of the three power heads.

Key outsourced components list

| NO. | Item | Brank | Origin |

| 1 | Linear Guides | HIWIN/PMI | Taiwan,China |

| 2 | Precision reducer and rack and pinion pair | ATLANTA | Germany |

| 3 | CNC system | Siemens 808D | Germany |

| 4 | Servo motor | Siemens | Germany |

| 5 | Slide drive servo motor and driver | Siemens | Germany |

| 6 | Frequency converter | Siemens | Germany |

| 7 | Hydraulic pump | Justmark | Taiwan,China |

| 8 | Hydraulic valve | ATOS/Justmark | Italy/Taiwan,China |

| 9 | Drag chain | Igus | Germany |

| 10 | Main electrical components such as buttons and indicators | Schneider | Franch |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for Factory Price Truck Beams – HD1715D-3 Drum horizontal three-spindle CNC drilling machine – FIN CNC , The product will supply to all over the world, such as: Lesotho, Bahrain, Nepal, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.