Factory Price Truck Beams – RS25 25m Rail Sawing Machine – FIN CNC

Factory Price Truck Beams – RS25 25m Rail Sawing Machine – FIN CNC Detail:

Product Parameters

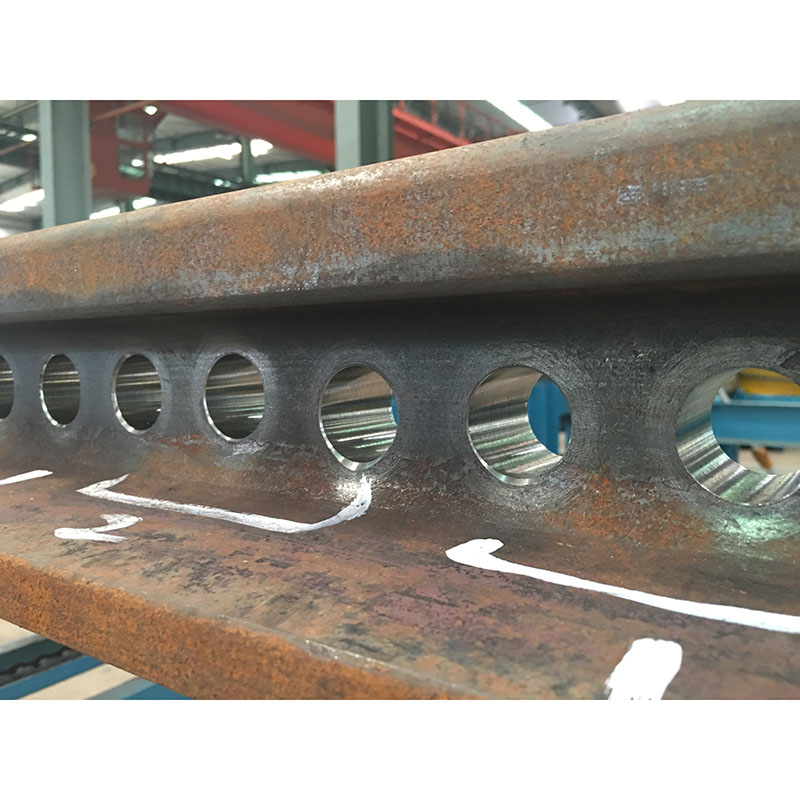

| Specification of processed rail | Stock rail | 43Kg/m, 50Kg/m, 60Kg/m, 75Kg/m etc. |

| Asymmetrical section rail | 60AT1, 50AT1, 60TY1, UIC33 etc. | |

| Maximum length of rail before sawing | 25000mm (It can also be used for 10m or 20m rails, with the function of measuring the length of raw materials.) | |

| Saw length of rail | 1800mm~25000mm | |

| Sawing unit | Cut off mode | Oblique cutting |

| Oblique cutting angle | 18° | |

| other | electrical system | Siemens 828d |

| Cooling mode | Oil mist cooling | |

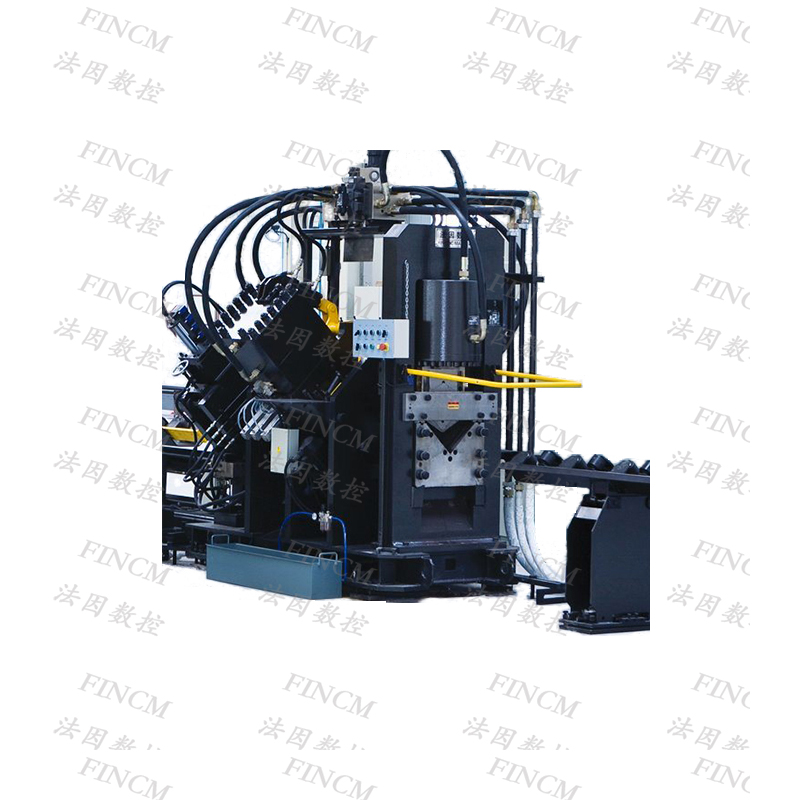

| clamping system | Vertical and horizontal clamping, hydraulic adjustable | |

| Feeding device | Number of feeding racks | 7 |

| Number of rails that can be placed | 20 | |

| Maximum moving speed | 8m/min | |

| Feeding roller table | Maximum conveying speed | 25m / min |

| Blanking device | Number of blanking racks | 9 |

| Number of rails that can be placed | 20 | |

| Maximum speed of lateral movement | 8 m / min | |

| Drawing unit | Maximum drawing speed | 30 m / min |

| Hydraulic system | 6Mpa | |

| Electrical system | Siemens 828D |

Details and advantages

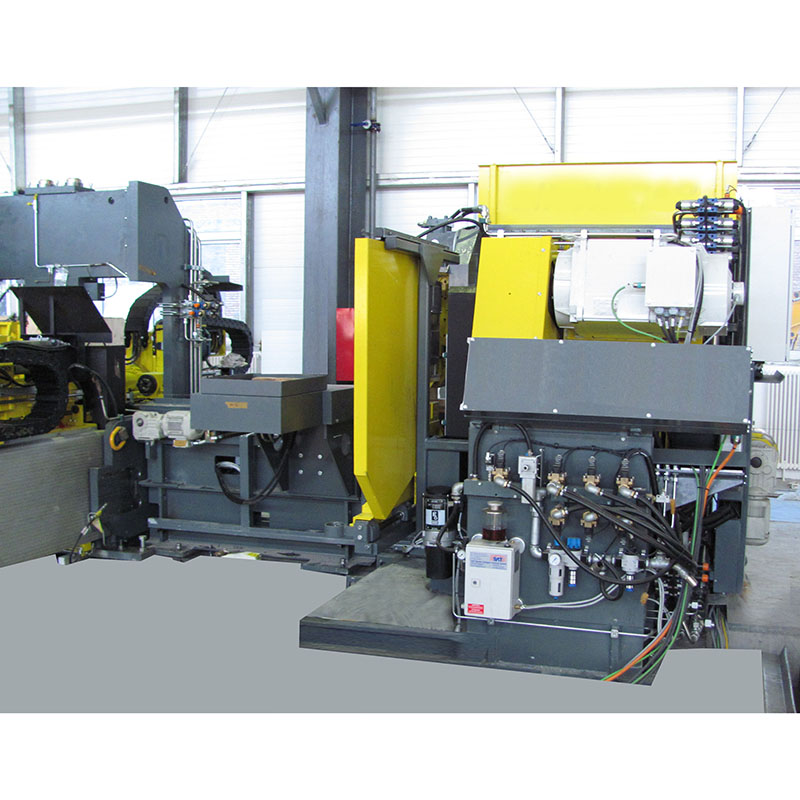

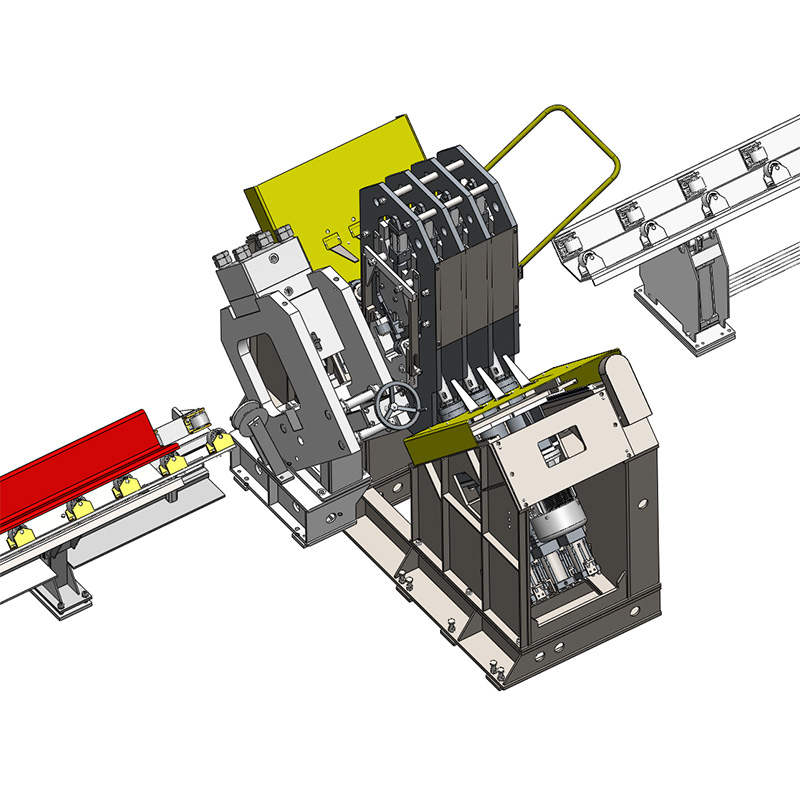

1. The feeding device is composed of 7 groups of feeding frames. It is used to support the rail and pull the rail to push the rail to be processed on the feeding rack onto the feeding roller table.

2. The unloading roller table is composed of several groups, each of which is independently driven and distributed between the loading frames to support the rail and transport the rail to the sawing unit.

3. The spindle motor is connected with the reducer through the synchronous belt, and then drives the sawing rotation. The movement of the saw blade is guided by two high bearing capacity linear roller guide pairs fixed on the bed. The servo motor is driven by the synchronous belt and ball screw pair, which can realize the fast forward, work forward, fast backward and other actions of the saw blade.

4. Inkjet is fast, characters are clear, beautiful, not falling off, not fading. The maximum number of characters is 40 at a time.

5. A flat chain chip remover is installed under the bed of the sawing unit, which is a head up structure and discharges the iron chips produced by sawing into the outside iron chip box.

6. Equipped with external cooling oil mist cooling device to cool the saw blade to ensure its service life. The amount of oil mist can be adjusted.

7. The machine is equipped with automatic centralized lubrication device, which can automatically lubricate the linear guide pairs, ball screw pairs, etc. Ensure the stability of the machine.

Key outsourced components list

| NO. | Name | Brand | Remark |

| 1 | Linear guide pair | HIWIN/PMI | Taiwan, China |

| 2 | Numerical control system | Siemens | Germany |

| 3 | Servo motor and driver | Siemens | Germany |

| 4 | Upper computer | LENOVO | China |

| 5 | Inkjet printing system | LDM | China |

| 6 | Gear and rack | APEX | Taiwan, China |

| 7 | Precision reducer | APEX | Taiwan, China |

| 8 | Laser alignment device | SICK | Germany |

| 9 | Magnetic scale | SIKO | Germany |

| 10 | Hydraulic valve | ATOS | Italy |

| 11 | Automatic lubrication system | HERG | Japan |

| 12 | Main electrical components | Schneider | France |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Factory Price Truck Beams – RS25 25m Rail Sawing Machine – FIN CNC , The product will supply to all over the world, such as: Australia, Algeria, Islamabad, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing products, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!