Free sample for Punching Hole Machine - APM1412 CNC Angle Punching Shearing Machine – FIN CNC

Free sample for Punching Hole Machine - APM1412 CNC Angle Punching Shearing Machine – FIN CNC Detail:

Product Parameters

| NO. | Item | Parameters |

| 1 | Processing range of angle steel | 40*40*3-140*140*12(Q420) |

| 2 | Maximum punching diameter | φ25.5mm(12mm thick, Q420)Nominal punching force 950KN |

| 3 | Nominal marking force | 1030KN |

| 4 | Number of punches per side | 3 |

| 5 | Number of punch rows on each side | arbitrarily |

| 6 | Number of print header groups | 4 groups |

| 7 | Number of prefix in each group | 18 |

| 8 | Prefix size | 14*10mm |

| 9 | Maximum length of blank | 12m |

| 10 | Cut off mode | Single blade cutting |

| 11 | Cut off nominal force | 1800KN |

| 12 | Number of NC axes | 3 |

| 13 | Feeding speed of angle steel | 40m/min |

| 14 | Punching rate | 1000 holes / h |

Detail And Advantages

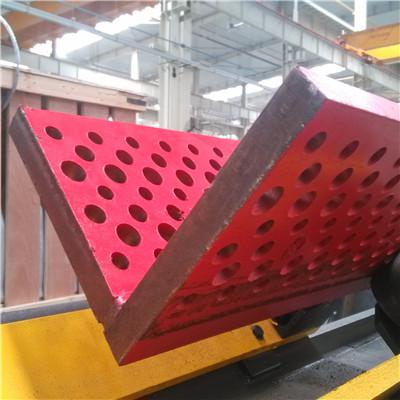

1、Punching unit adopts closed structure frame, which is very rigid.

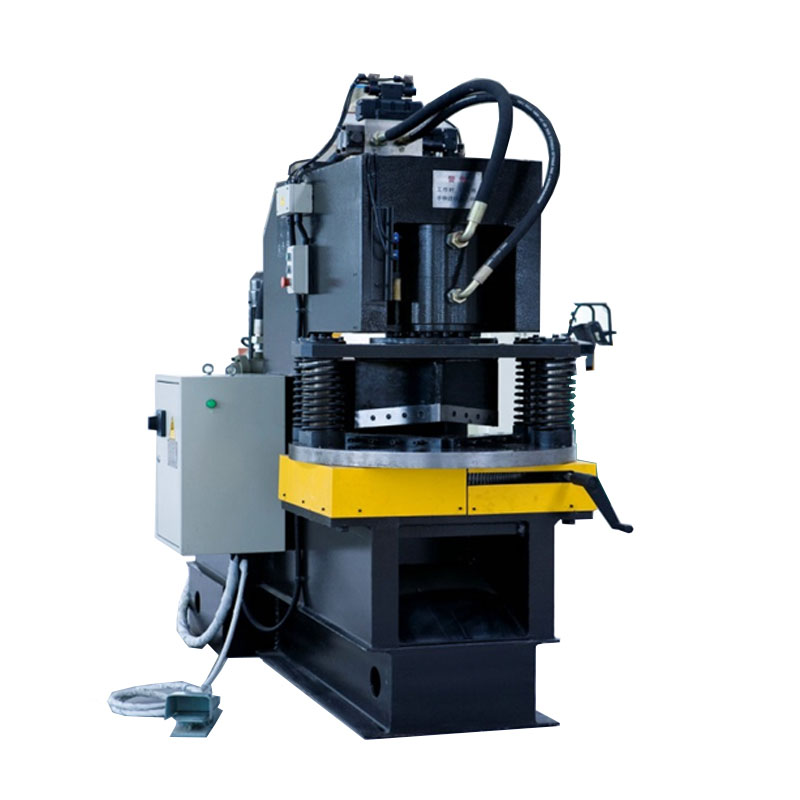

2、The single blade cutting mechanism ensures that the cutting section is neat and the shearing clearance is easy to adjust.

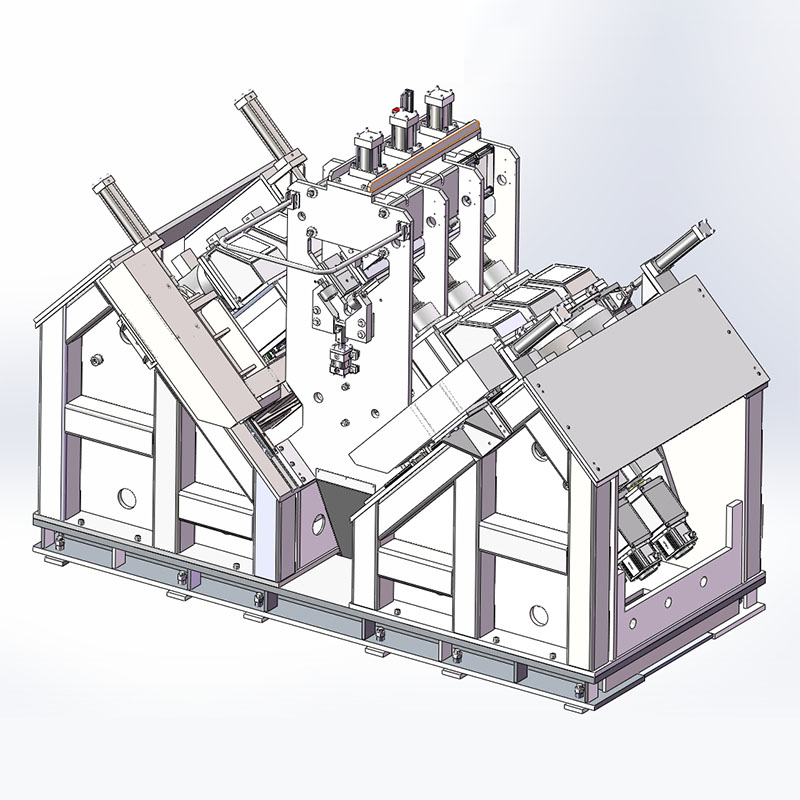

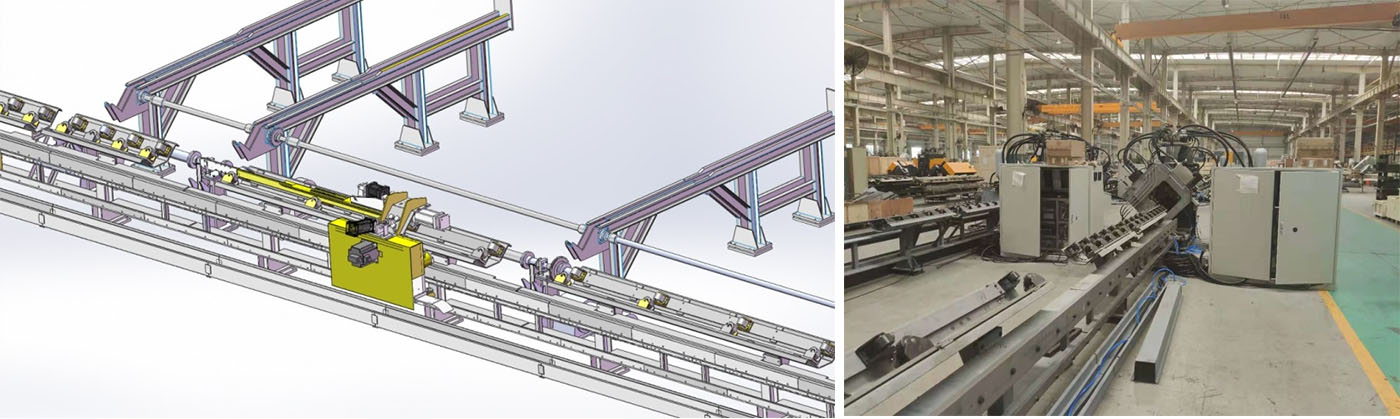

3、The CNC feeding trolley is clamped by pneumatic clamp to move and position rapidly. The angle is driven by servo motor, driven by rack and pinion and linear guide, with high positioning accuracy

4、This machine has a CNC axis: the movement and positioning of the feeding This machine has a CNC axis: the movement and positioning of the feeding gripper carriage.

5、The hydraulic pipeline adopts the ferrule structure, which effectively reduces the oil leakage and improves the stability of the machine.

6、It is easy to program by computer. It can display the material figure and the coordinate size of the hole position, so it is easy to check. It is very convenient to store and call the program, to display the graph, to diagnose the fault and to communicate with the computer.

Key Outsourced Components List

|

No. |

Name |

Brand |

Manufacture |

| 1 |

AC Servo Motor |

Panasonic |

Japan

|

| 2 |

PLC |

Mitsubishi |

|

| 3 |

Electromagnetic unloading valve |

ATOS/YUKEN |

Italy/Taiwan(China) |

| 4 |

Relief valve |

ATOS/YUKEN |

|

| 5 |

Electro-hydraulic directional valve |

JUSTMARK |

Taiwan (China) |

| 6 |

Double vane pump |

ALBERT |

America |

| 7 |

Manifold |

SMC/CKD |

Japan |

Note: The above is our fixed supplier. If the supplier can not supply the components in case of any special matter, we will adopt the components with the same level, but the quality is no worse than the above.

Product detail pictures:

Related Product Guide:

We are commitment to offer you the aggressive price tag ,exceptional products and solutions high-quality, as well as fast delivery for Free sample for Punching Hole Machine - APM1412 CNC Angle Punching Shearing Machine – FIN CNC , The product will supply to all over the world, such as: Italy, Bangladesh, Manchester, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.