Hot sale CNC Milling Machine Vertical - APM1010 CNC Angle Steel Punching Shearing Machine – FIN CNC

Hot sale CNC Milling Machine Vertical - APM1010 CNC Angle Steel Punching Shearing Machine – FIN CNC Detail:

Product Parameters

| NO. | Item | Parameters |

| 1 | Angle size | 40x40x3~100x100x10mm |

| 2 | Max. raw material angle profile length | 12m |

| 3 | Max. punching capacity (Hole Diameter x Material Thickness mm) |

Φ25.5mm x10mm |

| 4 | Nominal punching force | 440KN |

| 5 | Nominal marking force | 1030KN |

| 6 | Nominal cutting force | 1100KN |

| 7 | No. of character group | 4 |

| 8 | No. of character in each character group | 18 |

| 9 | Character size | 14x10x19mm |

| 10 | Cutting mode | Single-blade shearing |

| 11 | Range of stadia | 20~170 (stepless) |

| 12 | No. of punch on each side | 2 |

| 13 | Max. feeding speed | 60m/min |

| 14 | No. of CNC axes | 3 |

| 15 | Overall size | 25x7x2.2m |

| 16 | Total power | About 31.4KW |

| 17 | Machine weight | Approx. 13800Kg |

Details And Advantages

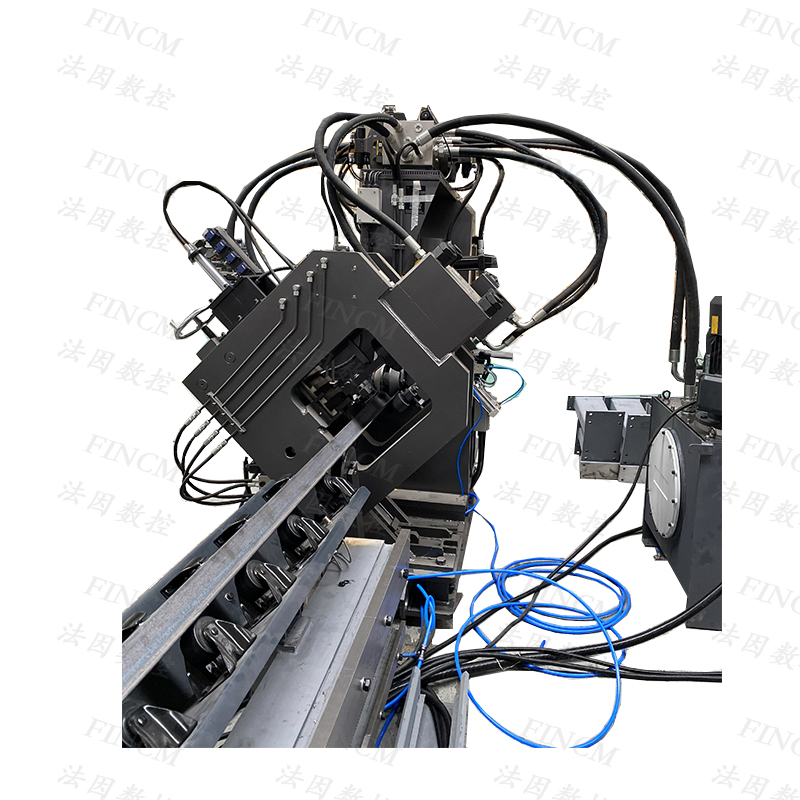

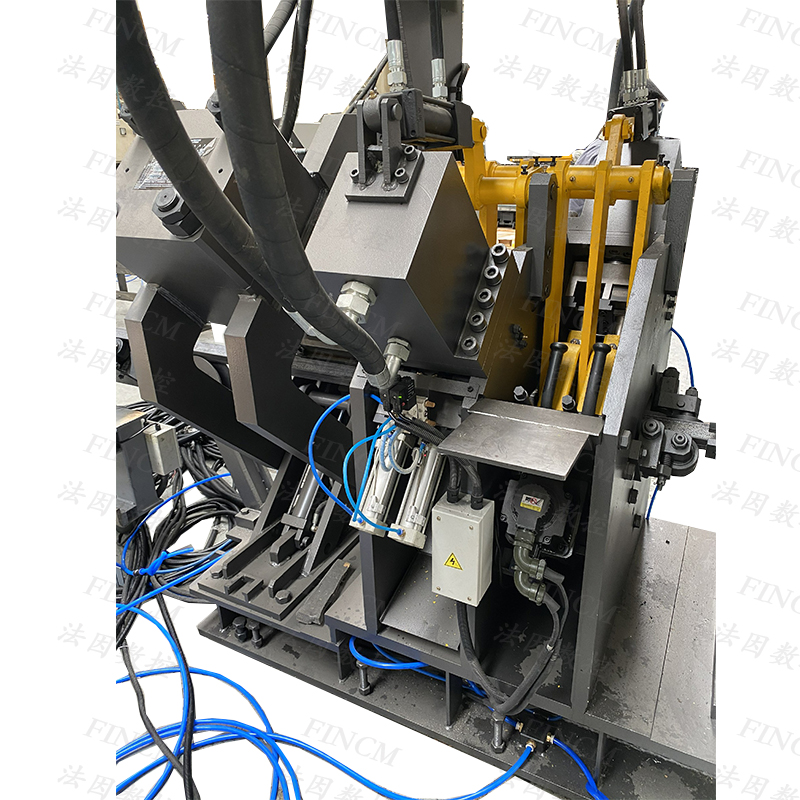

1、Punching unit adopts closed structure frame, which is very rigid.

2、The single blade cutting mechanism ensures that the cutting section is neat and the shearing clearance is easy to adjust.

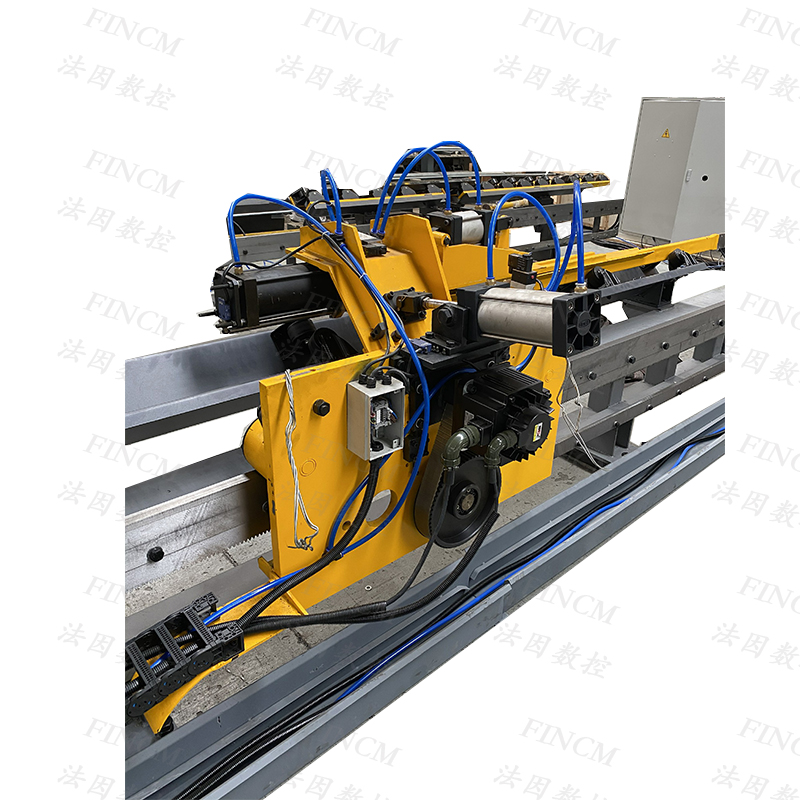

3、The CNC feeding trolley is clamped by pneumatic clamp to move and position rapidly. The angle is driven by servo motor, driven by rack and pinion and linear guide, with high positioning accuracy

4、This machine has a CNC axis: the movement and positioning of the feeding This machine has a CNC axis: the movement and positioning of the feeding gripper carriage.

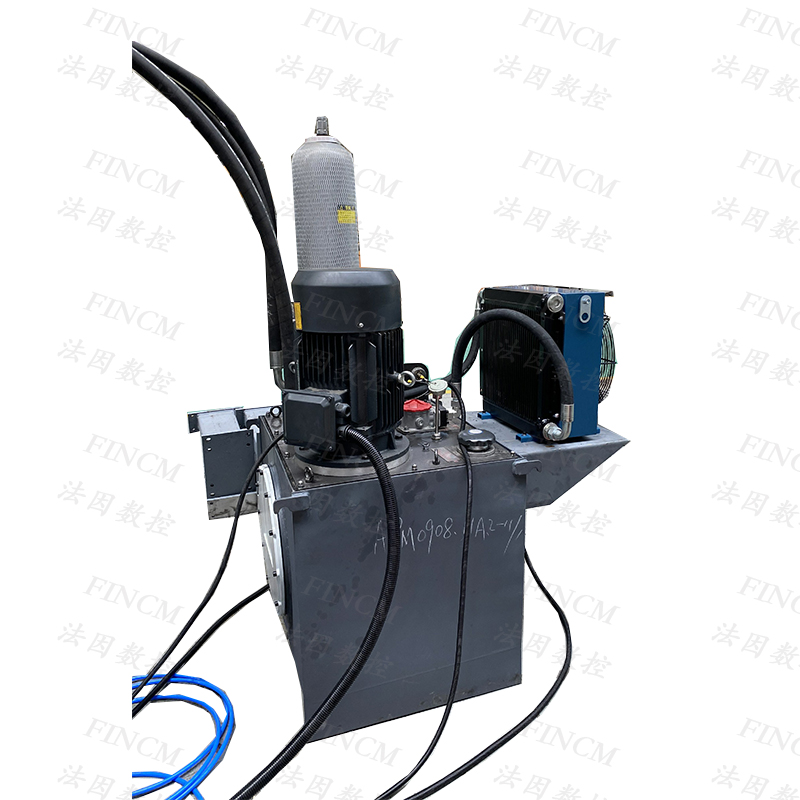

5、The hydraulic pipeline adopts the ferrule structure, which effectively reduces the oil leakage and improves the stability of the machine.

6、It is easy to program by computer. It can display the workpiece figure and the coordinate size of the hole position, so it is easy to check. It is very convenient to store and call the program, to display the graph, to diagnose the fault and to communicate with the computer.

Key Outsourced Components List

|

NO. |

Name |

Brand |

Origin Country |

|

1 |

AC Servo Motor |

DELTA |

China Taiwan

|

|

2 |

PLC |

DELTA |

|

|

3 |

Electromagnetic unloading valve |

ATOS/YUKEN |

Italy/China Taiwan

|

|

4 |

Relief valve |

ATOS/YUKEN |

|

|

5 |

Electro-hydraulic directional valve |

JUSTMARK |

China Taiwan |

|

6 |

Vane pump |

ALBERT |

USA |

|

7 |

Manifold |

AirTAC |

China Taiwan

|

|

8 |

Air Valve |

AirTAC |

|

|

9 |

Cylinder |

SMC/CKD |

Japan

|

|

10 |

Duplex |

SMC/CKD |

|

|

11 |

Computer |

Lenovo |

China |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

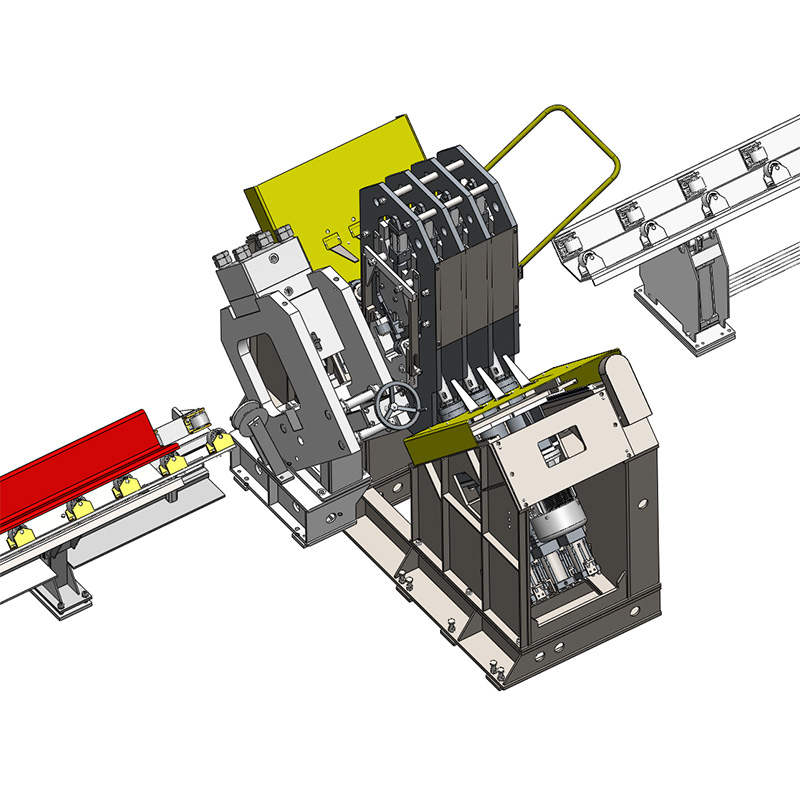

Product detail pictures:

Related Product Guide:

In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for Hot sale CNC Milling Machine Vertical - APM1010 CNC Angle Steel Punching Shearing Machine – FIN CNC , The product will supply to all over the world, such as: San Francisco, Senegal, Munich, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!