Manufacturer for CNC Metal Milling Machine - Hydraulic Angle Notching Machine – FIN CNC

Manufacturer for CNC Metal Milling Machine - Hydraulic Angle Notching Machine – FIN CNC Detail:

Product Parameters

| No. | Item | Parameter | |

| ACH140 | ACH200 | ||

| 1 | Nominal force | 560 KN | 1000KN |

| 2 | Rated pressure of hydraulic system | 22Mpa | |

| 3 | Number of no-load running | 20 times/min | |

| 4 | Single blade cutting |

140*140*16mm (material Q235-A, Max. Tensile Strengthσb≈410MPa) |

200*200*20mm (material Q235-A, Max. Tensile Strengthσb≈410MPa) |

| 5 | 140*140*14mm (material 16Mn, Max. Tensile Strengthσb≈600MPa) |

||

| 6 | 140*140*12mm (material Q420, Max. Tensile Strengthσb≈680MPa) |

200*200*16mm (material Q420, Max. Tensile Strengthσb≈680MPa) |

|

| 7 | Shearing angle | 0°~45° | |

| 8 | Maximum cutting length | 200 mm | 300mm |

| 9 | Square angle cutting |

140*140*12mm(Q235-A, Maximum tensile strengthσb≈410MPa) | 200*200*16mm(Q235-A, Maximum tensile strengthσb≈410MPa) |

| 10 | 140*140*10mm(16Mn, Maximum tensile strengthσb≈600MPa) | 200*200*12mm(16Mn, Maximum tensile strengthσb≈600MPa) | |

| 11 | Ambient temperature | 0℃~40℃ | |

| 12 | Motor power of hydraulic pump | 15KW | 18.5KW |

| 13 | Machine overall size (L*W*H) |

2000*1100*1850mm | 2635*1200*2090MM |

| 14 | Machine weight | About 3000kg | About 6500kg |

Details and advantages

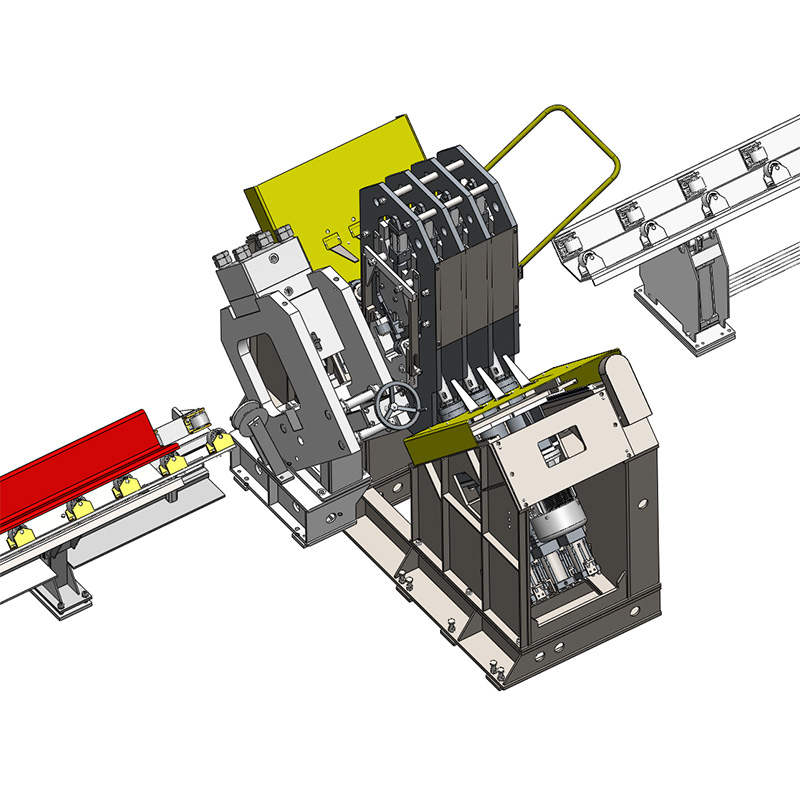

This product is composed of a main machine, cutting mould, and a hydraulic station, and is equipped with an electrical system to fulfill angle cutting.

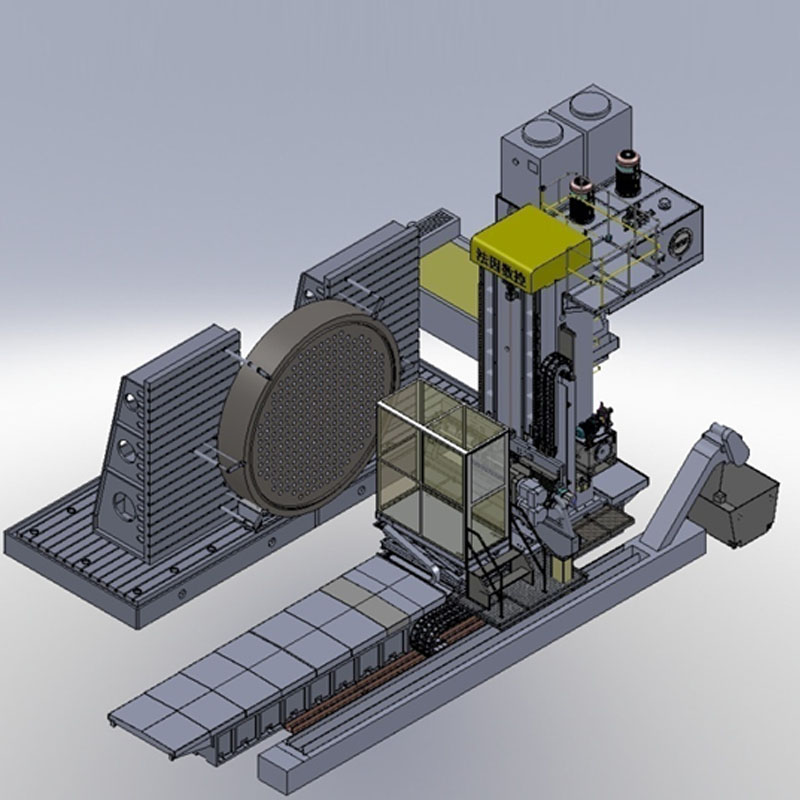

1. Main machine

The main machine is welded by steel plates in a C shape. The upper part is the oil cylinder, and the lower part is the working table, which provides support for the mould and meets the strength and rigidity requirements of the machine.

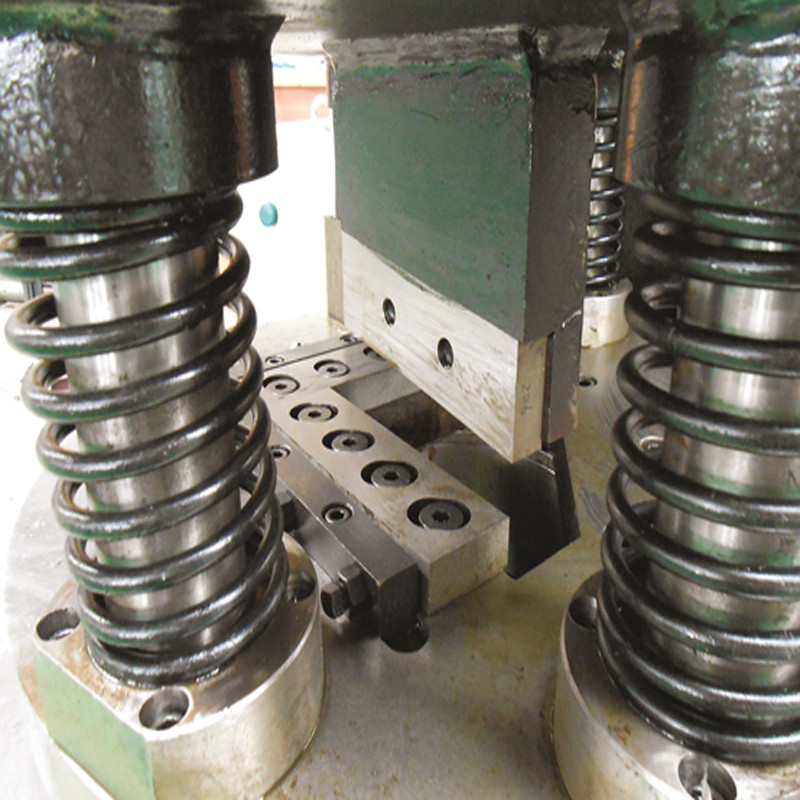

2. Mould

The mould part is guided by sliding rails, this structure bears large partial loads and has high guiding accuracy.

3. Hydraulic station

The hydraulic system is composed of oil tank, motor, high and low pressure pump, control valve, oil filter shearing cylinder, etc. It is the power source of shearing cylinder. The electromagnetic reversing valve, overflow valve, unloading valve, etc. are imported parts with reliable performance and long service life.

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for Manufacturer for CNC Metal Milling Machine - Hydraulic Angle Notching Machine – FIN CNC , The product will supply to all over the world, such as: Chicago, Czech republic, Australia, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, thorough meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!