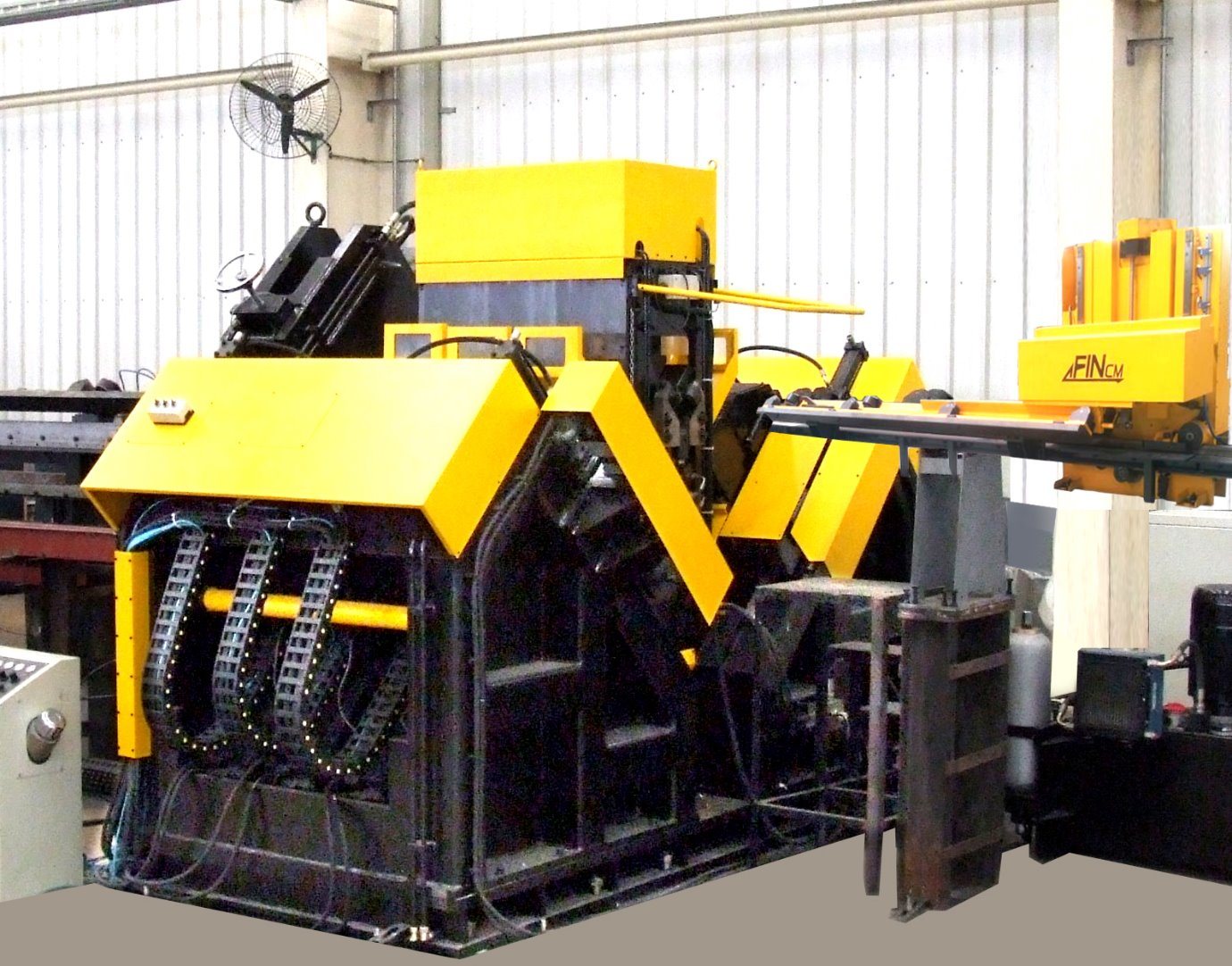

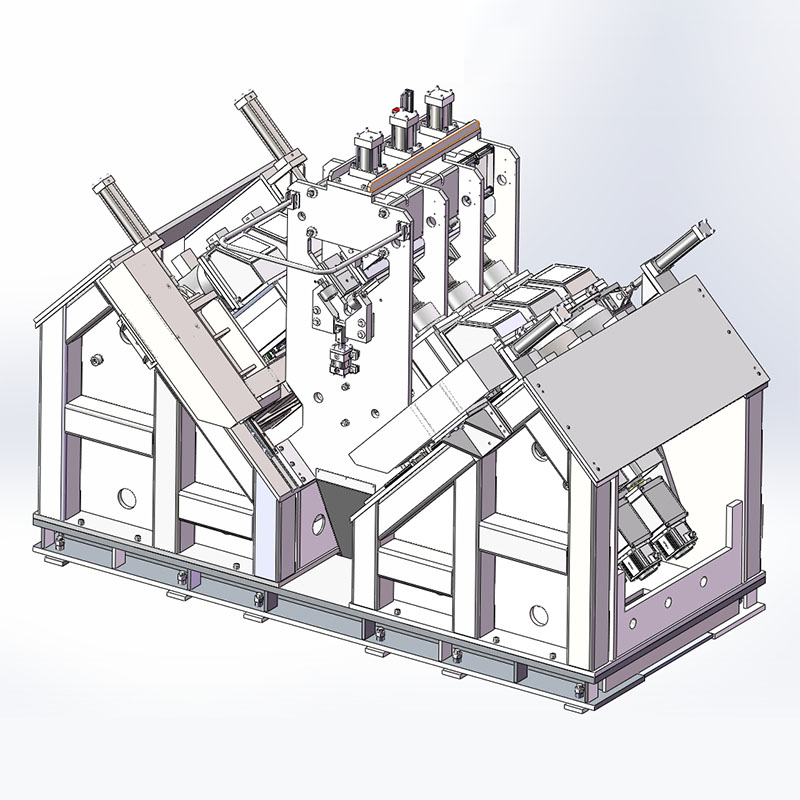

Popular Design for Metal Saw Cutting Machine - BL3635 Cnc Angle Steel Drilling Marking Machine – FIN CNC

Popular Design for Metal Saw Cutting Machine - BL3635 Cnc Angle Steel Drilling Marking Machine – FIN CNC Detail:

Product Parameters

| NO. | ||

| 1 | Angle size | 140×140×10 – 360×360×35 |

| 2 | Range of stadia | 50 ~ 330(stepless) |

| 3 | The quantity of punching row per side | arbitrariness |

| 4 | Quantity of drilling spindle per side | 3 |

| 5 | Range of drilling diameter(high-speed steel twist drill) | φ17.5 ~ φ40mm |

| 6 | Motor power of drilling spindle | 2×5.5 |

| 7 | Rotation speed of spindle(r/min) | 180 ~ 560(stepless adjustment) |

| 8 | Nominal marking force | 1200Kn |

| 9 | Feeding speed(mm/min) | 20 ~ 280 |

| 10 | Quantity of CNC axis | 3 |

| 11 | Max. length of material | 12m |

| 12 | Angle feeding speed (m/min) | 40 |

| 13 | Quantity of character group | 1 group |

Details And Advantages

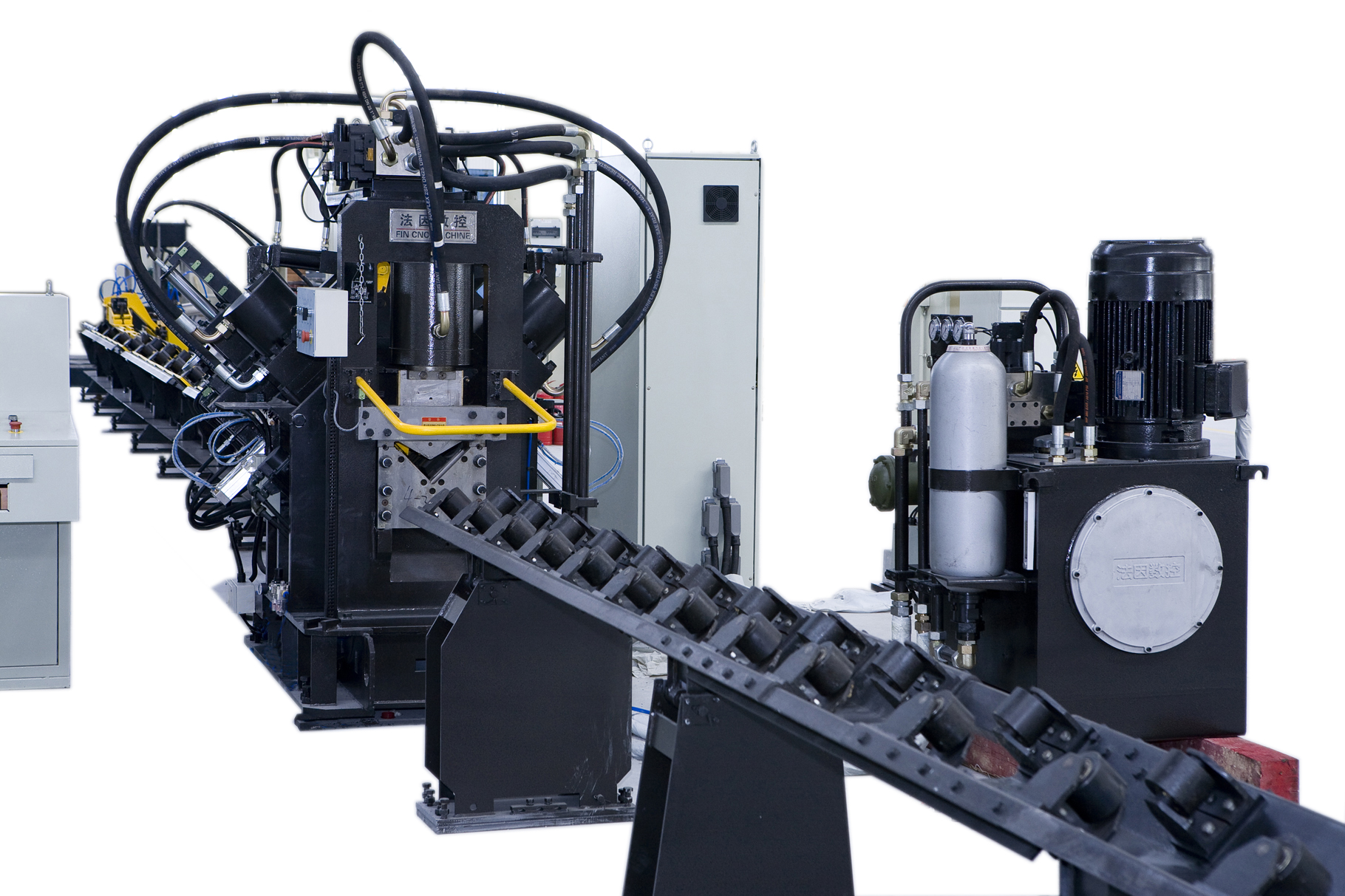

1、High degree of automation. The production line is equipped with automatic feeding device and transverse feeding conveyor.

2、All the holes and marking numbers/character on the angle material can be processed by the production line at one time automatically.

3、The positioning precision of hole making is very high.

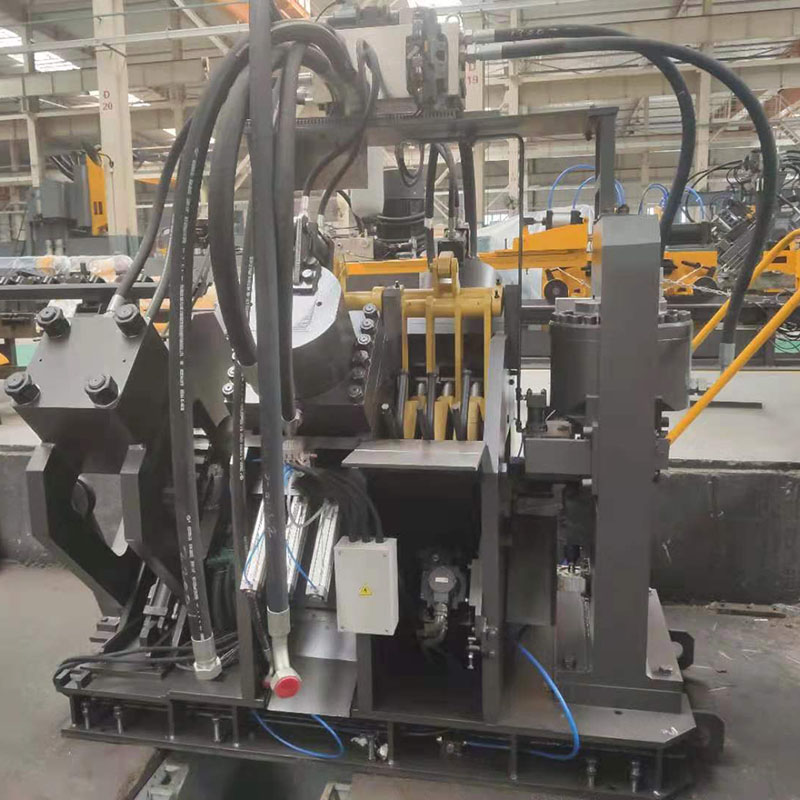

4、Drilling efficiency and drilling quality are high. The drilling unit is equipped with six groups of CNC drilling power .

5 、There are three drilling groups on each side of the angle material.

6、 The drilling spindle is equipped with disc spring automatic broach mechanism.

7、 The handle is very convenient.

8 、MQL (minimum quantities of lubricant) cooling system is the most advanced cooling system in the world.

Key Outsourced Component List

|

No. |

Name |

Brand |

Country |

|

1 |

AC Servo motor |

Panasonic / Siemens |

Japan |

|

2 |

Orientation module |

Yokogawa |

Japan |

|

3 |

Program controller |

Yokogawa |

Japan |

|

4 |

Proximity switch |

AUTONICS |

Korea |

|

5 |

Electromagnetic valve |

ATOS/Yuken |

Italy/ Taiwan China |

|

6 |

relief valve |

ATOS/Yuken |

Italy/ Taiwan China |

|

7 |

Pressure reducing valve |

ATOS/Yuken |

Italy/ Taiwan China |

|

8 |

Guide |

HIWIN/CSK |

Taiwan China |

|

9 |

Pneumatic combined unit |

SMC/CKD |

Japan |

|

10 |

Air valve |

AIRTAC |

Taiwan China |

|

11 |

Cylinder |

AIRTAC |

Taiwan China |

Note: The above is our fixed supplier. If the supplier can not supply the components in case of any special matter, we will adopt the components with the same level, but the quality is no worse than the above.

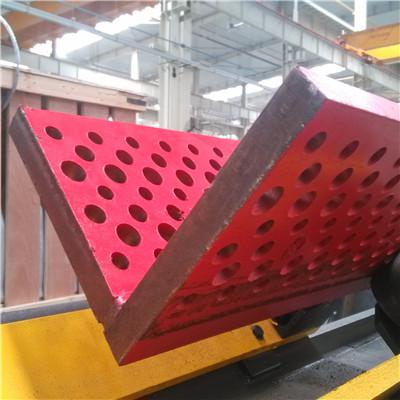

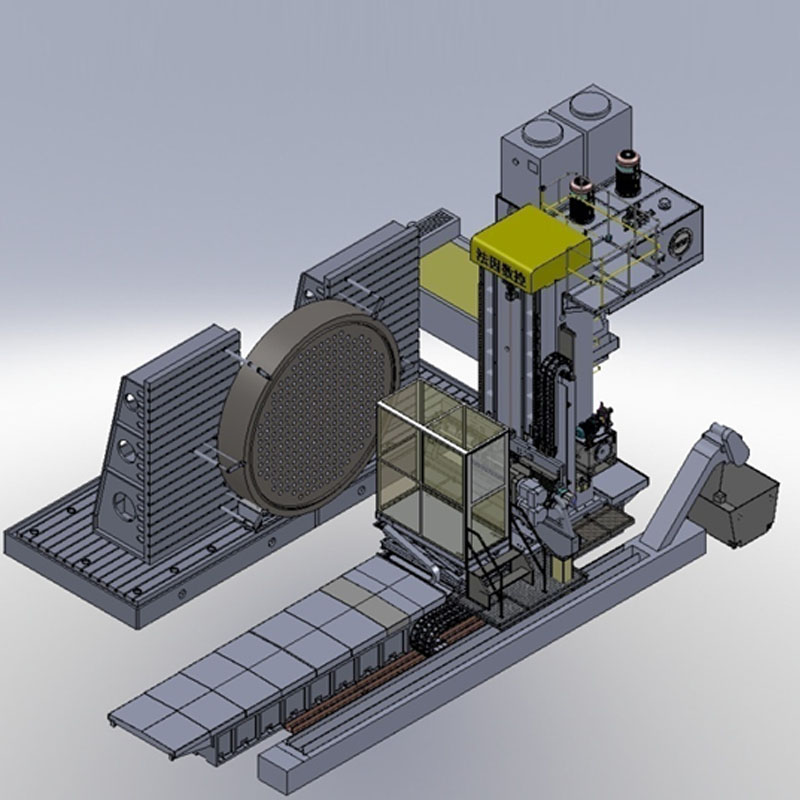

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Popular Design for Metal Saw Cutting Machine - BL3635 Cnc Angle Steel Drilling Marking Machine – FIN CNC , The product will supply to all over the world, such as: Chicago, Cambodia, Palestine, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!