Wholesale OEM/ODM China CNC High-Speed Drilling Machine for Rail-Road

We depend on sturdy technical force and continually create sophisticated technologies to satisfy the demand of Wholesale OEM/ODM China CNC High-Speed Drilling Machine for Rail-Road, High quality, timely service and Aggressive rate, all earn us a excellent fame in xxx field despite the international intense competition.

We depend on sturdy technical force and continually create sophisticated technologies to satisfy the demand of China CNC Machine Tools, Railroad Rail Drilling Chamferring Machine, With the superior and exceptional service, we’ve been well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. “Quality”, “honesty” and “service” is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

Product Parameters

| Specification of processed rail | Type of rail | 43Kg/m, 50Kg/m, 60Kg/m, 75Kg/m, UIC54, UIC60 |

| AT rail model | 50AT, 60 AT, UIC60D40 | |

| Special section wing rail | 60TY | |

| Rail size range | Bottom width | 114-152mm |

| Rail height | 128-192mm | |

| Web thickness | 14.5-44mm | |

| Rail length (after sawing) | 6-25m | |

| Rail material type | U71Mn σb≥90Kg/mm² HB250PD3 σb≥98Kg/mm² HB290-310 | |

| Drilling head | Diameter | φ20~φ33 |

| Length range | 3D~4D | |

| Processing requirements | Range of hole height | 35~100mm |

| Hole diameter numbers on each rail | 1~4 types | |

| Allowable tolerance of adjacent hole spacing | ±0.3mm | |

| Allowable tolerance between rail end face and nearest hole distance | ±0.5mm | |

| Allowable tolerance of farthest hole distance of rail | ±0.5mm | |

| Allowable tolerance of hole diameter size | 0~+0.3mm | |

| Hole wall roughness | Ra12.5 | |

| Allowable tolerance of hole center height (from rail bottom) | ±0.3mm | |

| Mobile column (including drilling power box) | Quantity | 1 set |

| Spindle taper hole | BT50 | |

| Spindle speed range (stepless speed regulation) | 10~3200r/min | |

| Spindle Servo motor power | 37kW | |

| Vertical slide travel (Y axis) | 800mm | |

| Vertical slide (Y-axis) servo motor power | 3.1kw | |

| Horizontal drilling feed stroke (Z axis) | 350mm | |

| Horizontal drilling feed (Z axis) servo motor power | 3.1kw | |

| Column horizontal travel stroke (X axis) | 25m | |

| Column horizontal movement (X axis) servo motor power | 3.1kw | |

| X-axis maximum moving speed | 10m/min | |

| Y, Z axis maximum moving speed | 8m/min | |

| Electric permanent magnet sucker | Quantity | 1 set |

| Sucker size (L × w × h) | 250×200×120mm | |

| Working suction | ≥200N/cm² | |

| Side push cylinder | Cylinder diameter × stroke | Φ50×70mm |

| Single cylinder side thrust | 700Kg | |

| Lifting roller table | Quantity | 1 set |

| Conveying speed | ≤15m/min | |

| Auxiliary hold down cylinder | Quantity | 1 set |

| Pressing force | ≥1500Kg/set | |

| Chip removal | Chip conveyor type | Flat chain |

| Chip removal speed | 2m/min | |

| Chip removal motor power | 2.2kW | |

| Hydraulic system | Quantity | 2 sets |

| Hydraulic pump pressure / flow / power | 6-6.5Mpa/25L/min/4kW 1 set | |

| Hydraulic pump pressure / flow / power | 5.5-6Mpa/66L/min/7.5kW 1 set | |

| Electrical system | Numerical control system | Siemens 828D |

| Number of CNC axes | 5+1 | |

| Air source | Compressed air supply pressure | 0.6Mpa |

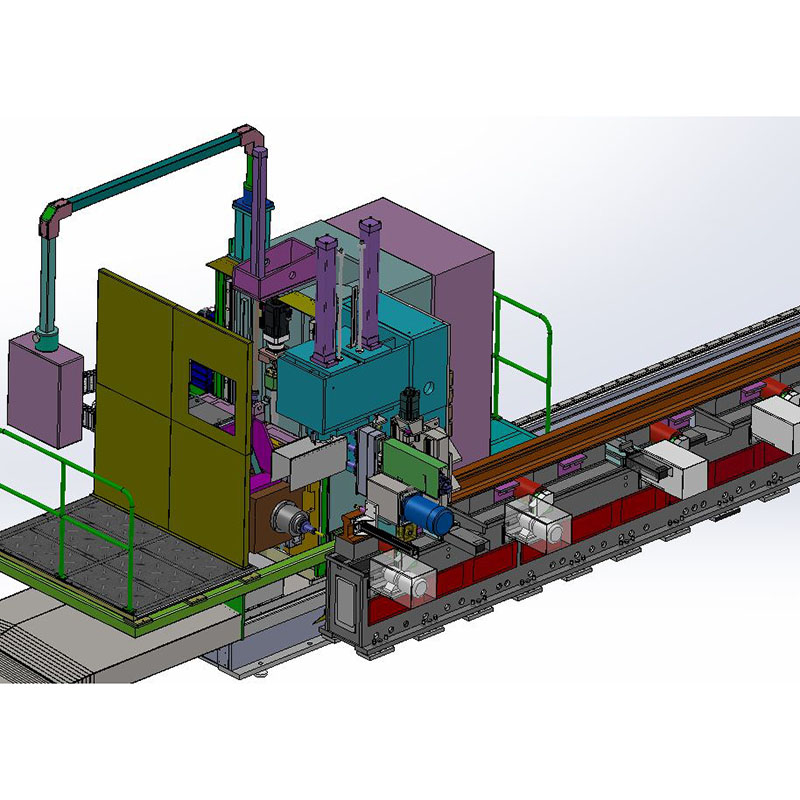

| Overall dimensions | (L× W× H) | About57×8.7×3.8m |

Details and advantages

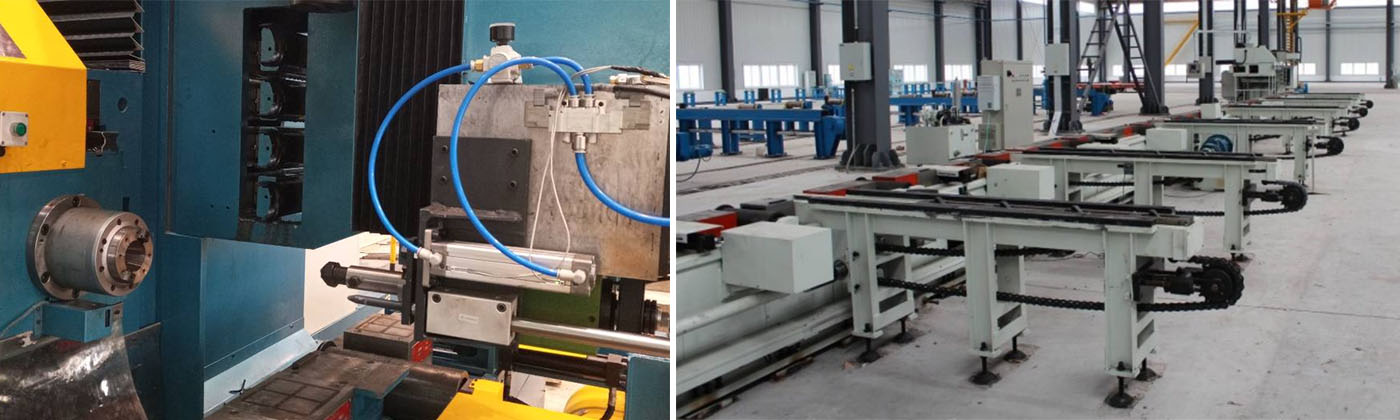

1. The bed of the machine is separated from the worktable, and the guide rail pair of the bed is arranged horizontally to increase the service life of the guide rail pair; Welded steel plate structure is adopted, and the accuracy and stability are ensured by annealing, stress relief and artificial aging treatment.

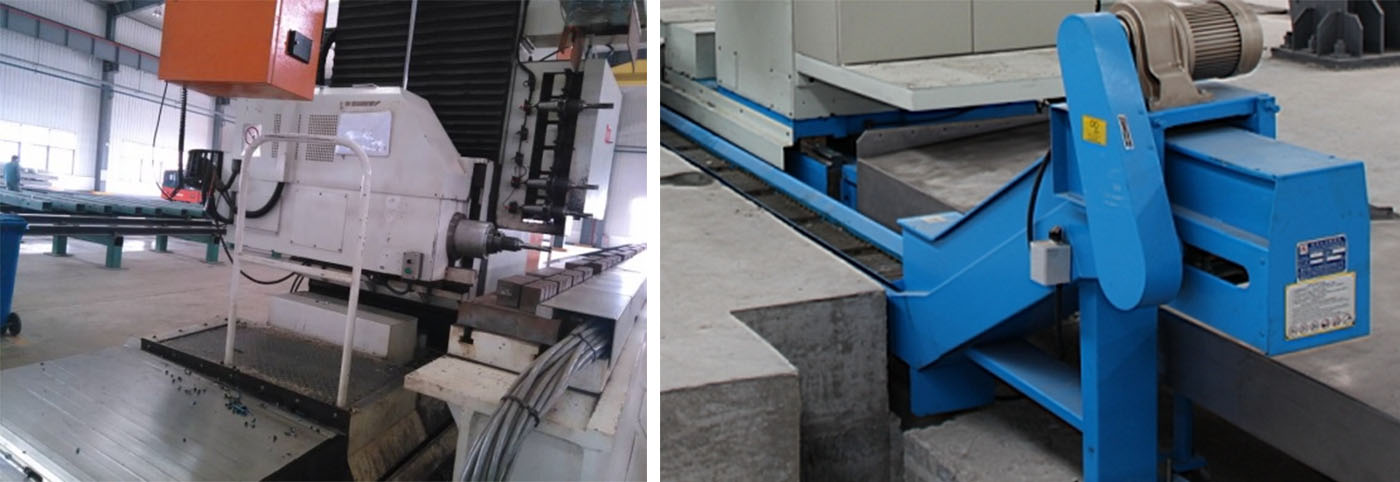

2. A powerful electromagnetic chuck is installed on the worktable of the machine tool to tighten the material. Pay attention to the order from the middle to both sides when the electromagnetic sucker is closed, and pay attention to the sealing and waterproof.

3. The mobile column adopts steel plate welding structure, which is annealed to remove stress and artificial aging treatment to ensure accuracy stability.

4. Chain plate automatic chip remover is flat chain type, and is installed in the middle of the bed work table.

5. The machine is equipped with two hydraulic stations, one is installed on the mobile column, which is mainly used for balancing cylinder, pressing cylinder and knife cylinder; Another is installed on the foundation, which is mainly used for lifting cylinder and pulling cylinder of lifting conveying roller table.

6. There are three CNC axes in the machine, each of which is guided by precision linear rolling guide pair.

7. The drilling tool adopts index able carbide u drill, and the spindle is cooled by air mist.

8. Siemens 828D CNC system is used in the CNC system, which can monitor the drilling process in real time.

Key outsourced components list

|

NO. |

Name |

Brand |

Country |

|

1 |

Ball guide pair |

HIWIN/PMI |

Taiwan(China) |

|

2 |

CNC system |

Siemens 828D |

Germany |

|

3 |

Servo motor |

Siemens |

Germany |

|

4 |

Hydraulic valve |

ATOS |

Italy |

|

5 |

Oil pump |

Justmark |

Taiwan(China) |

|

6 |

Drag chain |

IGUS/CPS |

Germany / Korea |

|

7 |

Spindle servo motor |

Siemens |

Germany |

|

8 |

Reducer |

ATLANTA |

Germany |

|

9 |

Precision spindle |

Kenturn |

Taiwan(China) |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.We depend on sturdy technical force and continually create sophisticated technologies to satisfy the demand of Wholesale OEM/ODM China CNC High-Speed Drilling Machine for Rail-Road, High quality, timely service and Aggressive rate, all earn us a excellent fame in xxx field despite the international intense competition.

Wholesale OEM/ODM China CNC Machine Tools, Railroad Rail Drilling Chamferring Machine, With the superior and exceptional service, we’ve been well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. “Quality”, “honesty” and “service” is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability