Best quality Angle Shear Machine - PD16C Double Table Gantry Mobile CNC Plate Drilling Machine – FIN CNC

Best quality Angle Shear Machine - PD16C Double Table Gantry Mobile CNC Plate Drilling Machine – FIN CNC Detail:

Product Parameters

| Item | Parameter name | Parameter value |

| Plate size | Plate overlap thickness | Max.80mm |

| Width*length | 1000mm×1650mm 1piece | |

| 825mm×1000mm 2piece | ||

| 500mm×825mm 3piece | ||

| Drill diameter | Φ12mm-Φ50mm | |

| Variable speed method | Inverter stepless speed change | |

| Rotating speed(RPM) | 120-560r/min | |

| Processing feed | Hydraulic stepless speed regulation | |

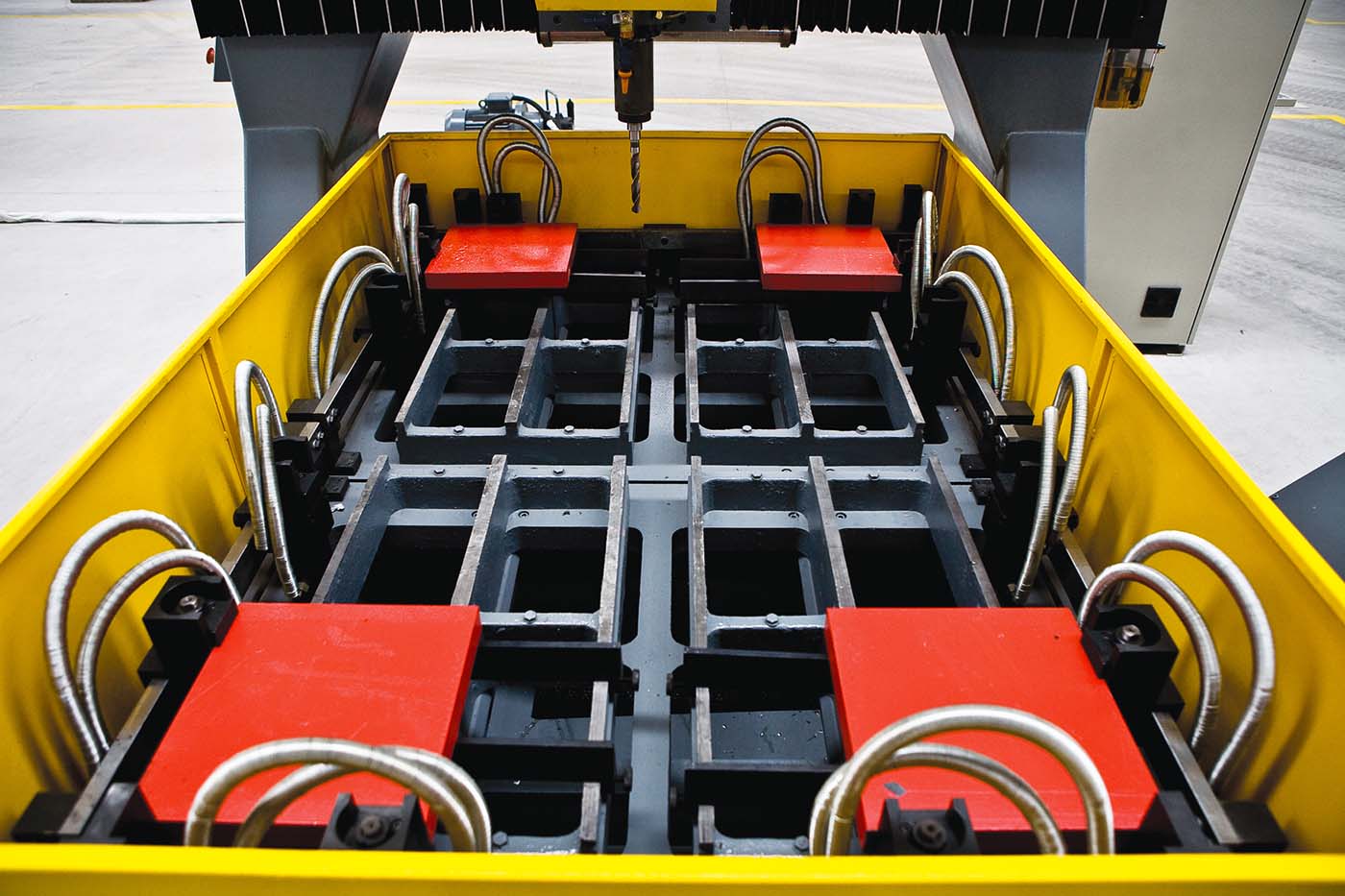

| Plate clamping | Clamping thickness | 15-80mm |

| Number of clamping cylinders | 12个 | |

| Clamping force | 7.5KN | |

| Motor | Spindle motor | 5.5KW |

| Hydraulic pump motor | 2.2KW | |

| Chip conveyor motor | 0.4KW | |

| Cooling pump motor | 0.25KW | |

| X axis servo motor | 1.5KW | |

| Y axis servo motor | 1.0KW | |

| Machine size | Length*width*height | about3160*3900*2780mm |

| Wight | Machine | about4000kg |

| Chip removal system | about400kg | |

| Stroke | X axis | 1650mm |

| Y axis | 1000mm |

Details and advantages

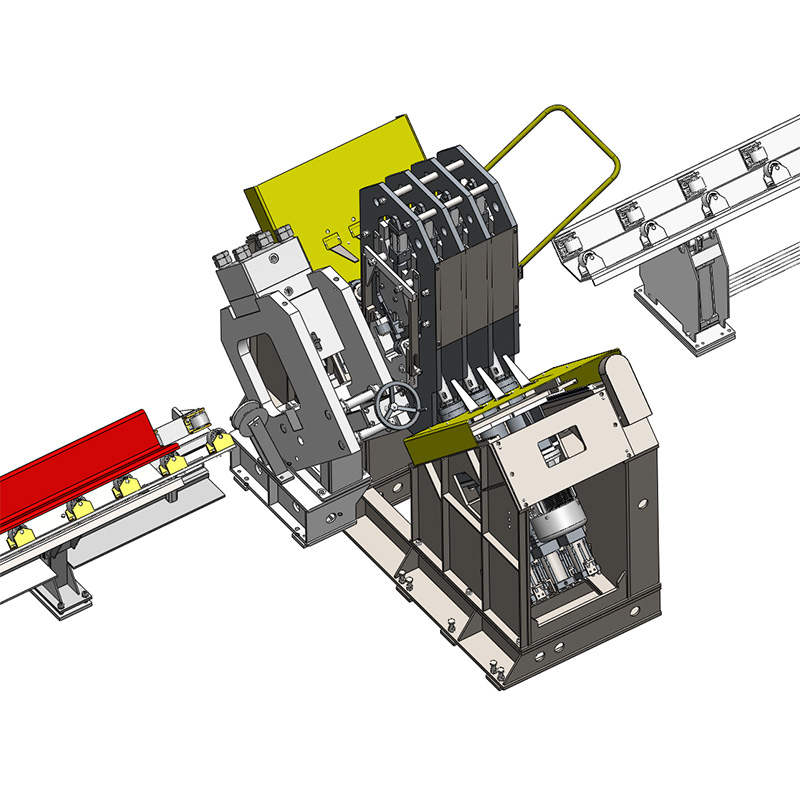

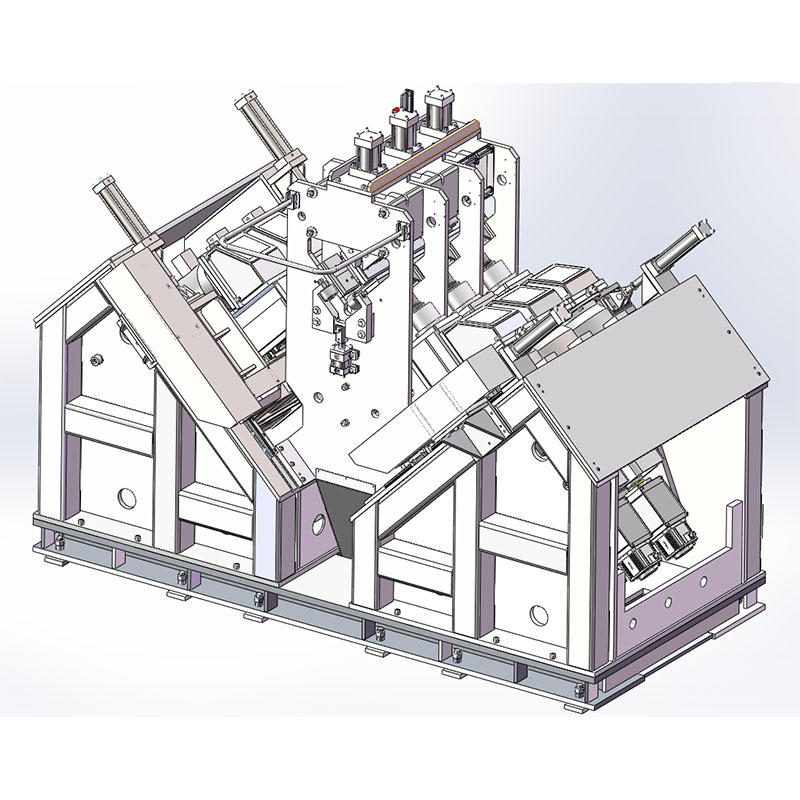

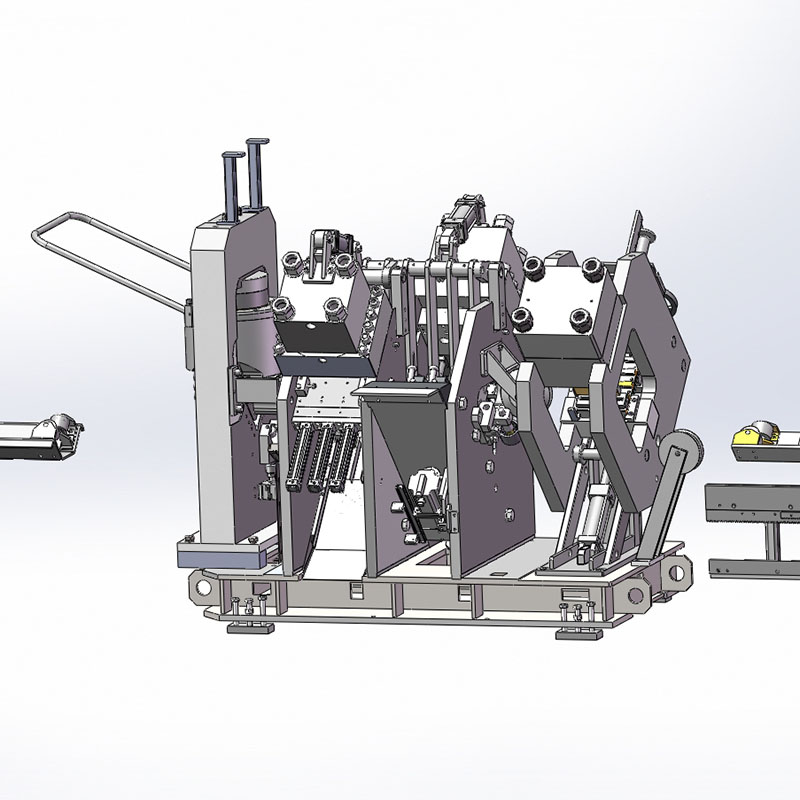

1. This machine is mainly composed of bed, gantry, transposition table (double table), drilling power head, hydraulic system, control system, centralized lubrication system, chip removal system, cooling system, quick-change chuck, etc.

2. This machine adopts the form of fixed bed and movable gantry. The gantry, bed and worktable are all welded structures, and after aging treatment, the accuracy is stable. The plate is clamped by hydraulic clamps, and the operator is controlled by a foot switch, which is convenient and labor-saving;

3. This machine has 2 CNC axes: the movement of the gantry (x axis); the movement of the drilling power head on the gantry beam (y axis). Each CNC axis is guided by a precision linear rolling guide, which is directly driven by AC servo motor + ball screw. Flexible movement and precise positioning.

4. The hydraulic automatic control stroke drilling power head is our company’s patented technology. There is no need to set any parameters before use, and the conversion between fast forward, work forward and fast reverse is automatically realized through the combined action of electro-hydraulic.

5. This machine tool adopts a centralized lubrication system instead of manual operation to ensure that the functional parts are well lubricated, improve the performance of the machine tool, and prolong its service life.

6. The control program adopts the upper computer programming software that is matched with the programmable controller independently developed by our company.

Product detail pictures:

Related Product Guide:

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for Best quality Angle Shear Machine - PD16C Double Table Gantry Mobile CNC Plate Drilling Machine – FIN CNC , The product will supply to all over the world, such as: Amman, Costa Rica, Pakistan, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our goods in China!

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.