Factory Outlets Punching Machine Hydraulic - Hydraulic Angle Notching Machine – FIN CNC

Factory Outlets Punching Machine Hydraulic - Hydraulic Angle Notching Machine – FIN CNC Detail:

Product Parameters

| No. | Item | Parameter | |

| ACH140 | ACH200 | ||

| 1 | Nominal force | 560 KN | 1000KN |

| 2 | Rated pressure of hydraulic system | 22Mpa | |

| 3 | Number of no-load running | 20 times/min | |

| 4 | Single blade cutting |

140*140*16mm (material Q235-A, Max. Tensile Strengthσb≈410MPa) |

200*200*20mm (material Q235-A, Max. Tensile Strengthσb≈410MPa) |

| 5 | 140*140*14mm (material 16Mn, Max. Tensile Strengthσb≈600MPa) |

||

| 6 | 140*140*12mm (material Q420, Max. Tensile Strengthσb≈680MPa) |

200*200*16mm (material Q420, Max. Tensile Strengthσb≈680MPa) |

|

| 7 | Shearing angle | 0°~45° | |

| 8 | Maximum cutting length | 200 mm | 300mm |

| 9 | Square angle cutting |

140*140*12mm(Q235-A, Maximum tensile strengthσb≈410MPa) | 200*200*16mm(Q235-A, Maximum tensile strengthσb≈410MPa) |

| 10 | 140*140*10mm(16Mn, Maximum tensile strengthσb≈600MPa) | 200*200*12mm(16Mn, Maximum tensile strengthσb≈600MPa) | |

| 11 | Ambient temperature | 0℃~40℃ | |

| 12 | Motor power of hydraulic pump | 15KW | 18.5KW |

| 13 | Machine overall size (L*W*H) |

2000*1100*1850mm | 2635*1200*2090MM |

| 14 | Machine weight | About 3000kg | About 6500kg |

Details and advantages

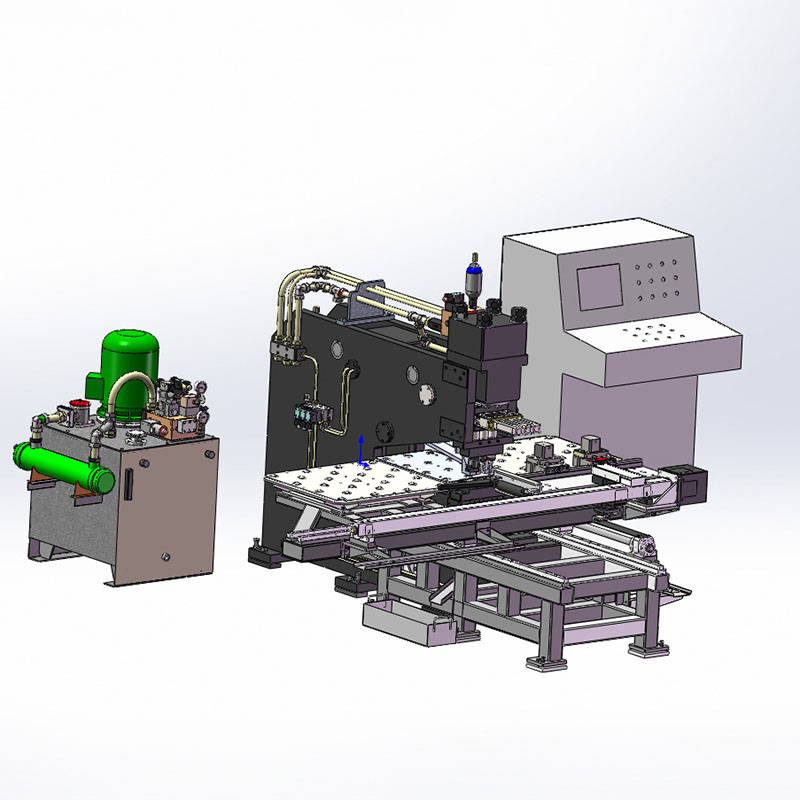

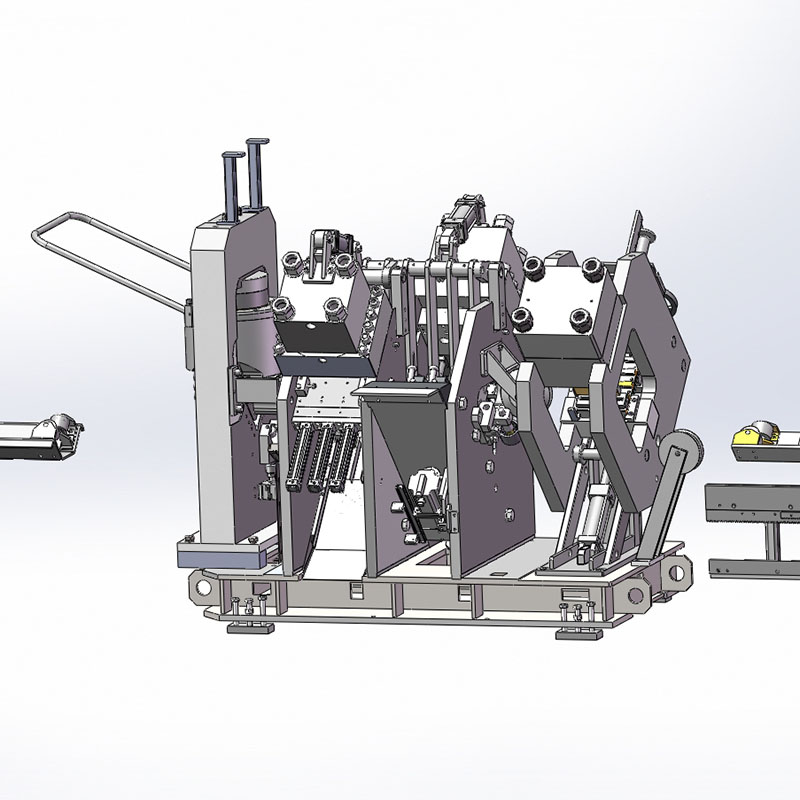

This product is composed of a main machine, cutting mould, and a hydraulic station, and is equipped with an electrical system to fulfill angle cutting.

1. Main machine

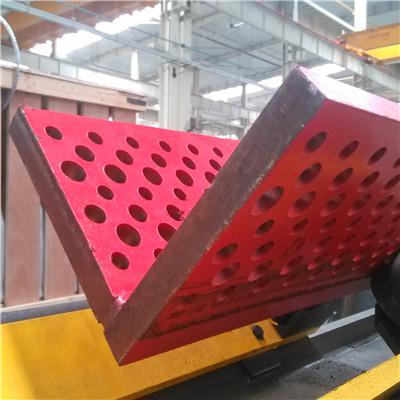

The main machine is welded by steel plates in a C shape. The upper part is the oil cylinder, and the lower part is the working table, which provides support for the mould and meets the strength and rigidity requirements of the machine.

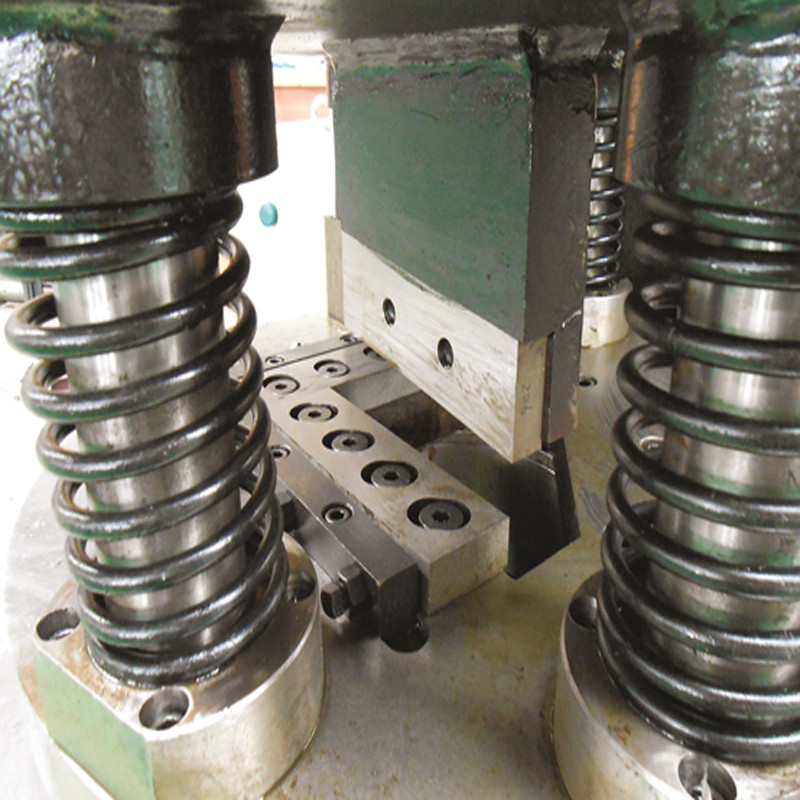

2. Mould

The mould part is guided by sliding rails, this structure bears large partial loads and has high guiding accuracy.

3. Hydraulic station

The hydraulic system is composed of oil tank, motor, high and low pressure pump, control valve, oil filter shearing cylinder, etc. It is the power source of shearing cylinder. The electromagnetic reversing valve, overflow valve, unloading valve, etc. are imported parts with reliable performance and long service life.

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Factory Outlets Punching Machine Hydraulic - Hydraulic Angle Notching Machine – FIN CNC , The product will supply to all over the world, such as: India, Germany, Qatar, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.