20.05.2022

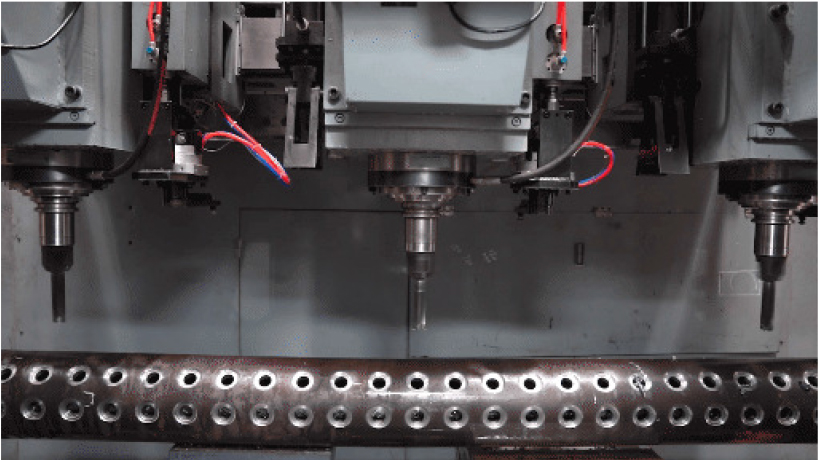

The CNC Drill jointly developed by SHANDONG FIN CNC MACHINE CO.,LTD and DONGFANG Boiler Group CO.,LTD has been debugged recently. The original three-dimensional CNC drill realizes the "Dual-machine combination", and the drilling is fully automatic under the control of the CNC system.

The “basin-shaped” groove(bevel) is processed at one time, and various operating indicators and product processing accuracy are excellent.

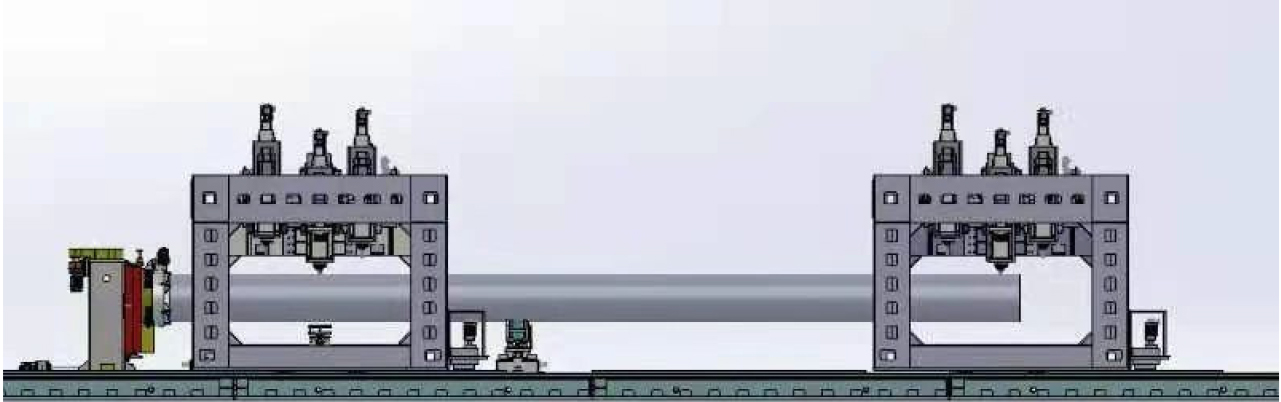

Model diagram of Double Gantry Six-axis High-speed Drilling Station

The successful trial production of the first batch of products marks the successful operation of the Double-gantry Six-axis High-speed CNC Drilling workstation. Make Shandong FINCM and DONGFANG Boiler the leader in the manufacture of boiler header drills in the domestic boiler industry. According to the international leading level, the workstation shows the strength of intelligent machine manufacturing.

In the manufacture of boiler headers, the number of header tubes is huge.

The traditional use of Radial Drills Machine for processing and control has low efficiency, unstable quality, and high labor intensity, which has restricted the mass production of headers for a long time.

The machining accuracy of pipe holes and grooves also hinders the application and promotion of pipe joint welding robots.

This workstation is the only highly automated machine in the boiler industry that is maturely used in the control and processing of headers. The two gantry can be controlled independently or in linkage to control the processing of the headers. It has high flexibility and the processing efficiency can reach 5-6 Radial Drills.

The workstation is equipped with an automatic detection system for the surface height of the material, which can automatically adapt to the side bending deformation of the header base metal, which ensures the consistency of the machining accuracy of the basin hole and meets the needs of the robot automatic welding process. At the same time, the clamping method in which the chuck movement automatically adapts to the position of the header is adopted, which greatly reduces the preparation time for material clamping adjustment.

The commissioning of the Double-Gantry Six-axis High-speed CNC Drilling Workstation has effectively solved the processing quality problems and production bottlenecks faced by the workshop production, reduced labor intensity, improved the welding quality of pipe joints, and laid a solid foundation for the realization of automatic welding of pipe joints.

Shandong FINCM has always practiced the business concept of "Quality establishes an enterprise, and technology strengthens an enterprise", and has taken the most important step towards intelligent transformation and upgrading, leading the development direction of intelligent container manufacturing.

Post time: May-20-2022