OEM/ODM Factory Metal CNC Milling Machine - CNC Drilling Shearing and Marking Machine for Angles Steel – FIN CNC

OEM/ODM Factory Metal CNC Milling Machine - CNC Drilling Shearing and Marking Machine for Angles Steel – FIN CNC Detail:

Product Parameters

| NO. | Item | Parameter | |||

| ADM3635 | BL3536 | ADM2532 | BL2532 | ||

| Angle size | 140 *140 *10 mm - 360 *360 *35 mm |

140 *140 *10 mm- 250 *250 *32 mm/ |

|||

| Range of stadia | 50mm-330mm (stepless) |

50mm-220mm (stepless) |

|||

| The quantity of drilling cow per side | Arbitrariness | ||||

| Quantity of drilling spindle per side | 3 | ||||

| Range of drilling diameter (hard metal) |

φ17.5 mm~ φ40mm | φ17.5 mm ~ φ26mm | |||

| Quantity of CNC axis | 9 | 3 | 9 | 3 | |

| Max length of angle | 12 m | ||||

| Angle feeding speed | 40 m/min | ||||

| Marking Force | 1030KN | ||||

Details and advantages

1. High degree of automation. The production line is equipped with automatic feeding device and transverse feeding conveyor.

2. All the holes and marking numbers/character on the angle material can be processed by the production line at one time automatically.

3. The positioning precision of hole making is very high.

4. Drilling efficiency and drilling quality are high. The drilling unit is equipped with six groups of CNC drilling power .

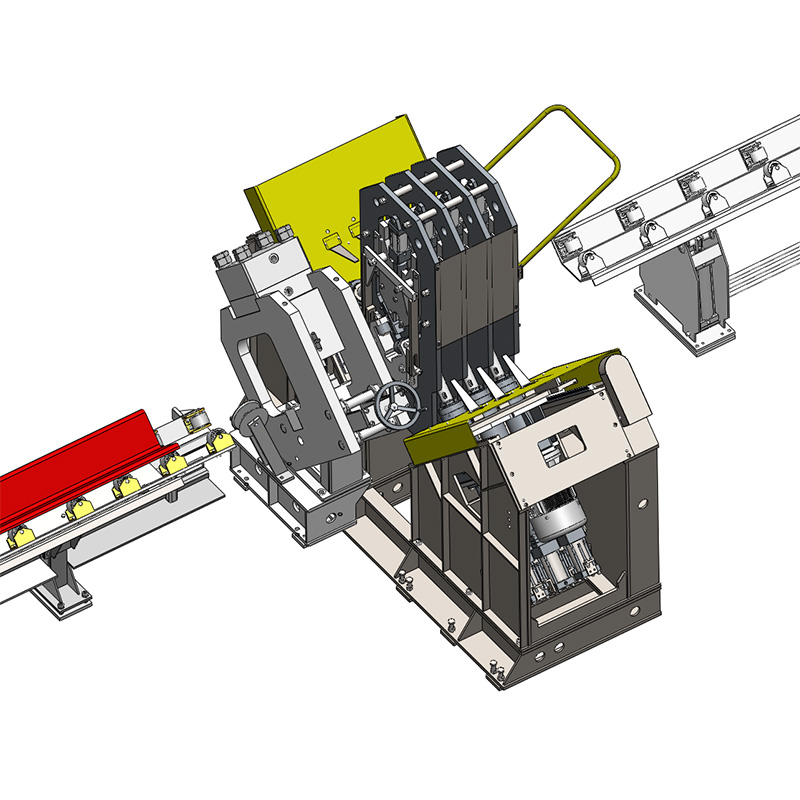

5. There are three drilling groups on each side of the angle material.

6. The drilling spindle is equipped with disc spring automatic broach mechanism.

7. The handle is very convenient.

8. MQL (minimum quantities of lubricant) cooling system is the most advanced cooling system in the world.

Key Outsourced Components List

| No. | Name | Brand | Country |

| 1 | AC Servo motor | Panasonic/Siemens | Japan/Germany |

| 2 | Linear Guides | Hiwin/CSK | Taiwan China |

| 3 | Flexible coupling | KTR | Germany |

| 4 | Rotary joint | Dublin | USA |

| 5 | Hydraulic valve | ATOS/Yuken | Italy/Japan |

| 6 | Pneumatic combined unit | SMC/AirTAC | Japan/Taiwan China |

| 7 | Air valve | AirTAC | Taiwan China |

| 8 | Cylinder | AirTAC | Taiwan China |

| 9 | CPU | Mitsubishi | Japan |

| 10 | Positioning module | Mitsubishi | Japan |

| 11 | Double vane pump | Albert | USA |

| Orientation module | Yokogawa | Japan | |

| 12 | Program controller | Yokogawa | Japan |

| 13 | Proximity switch | AUTONICS | Korea |

| 14 | Electromagnetic valve | ATOS/Yuken | Italy |

| 15 | Relief valve | ATOS/Yuken | Italy |

| 16 | Pressure reducing valve | ATOS/Yuken | Italy |

Note: The above is our standard supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

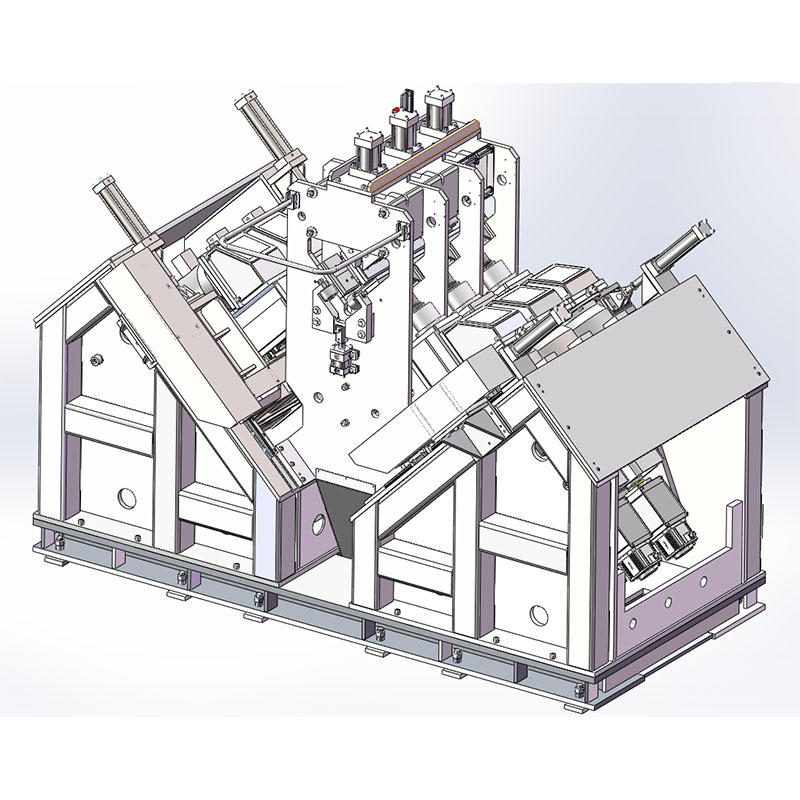

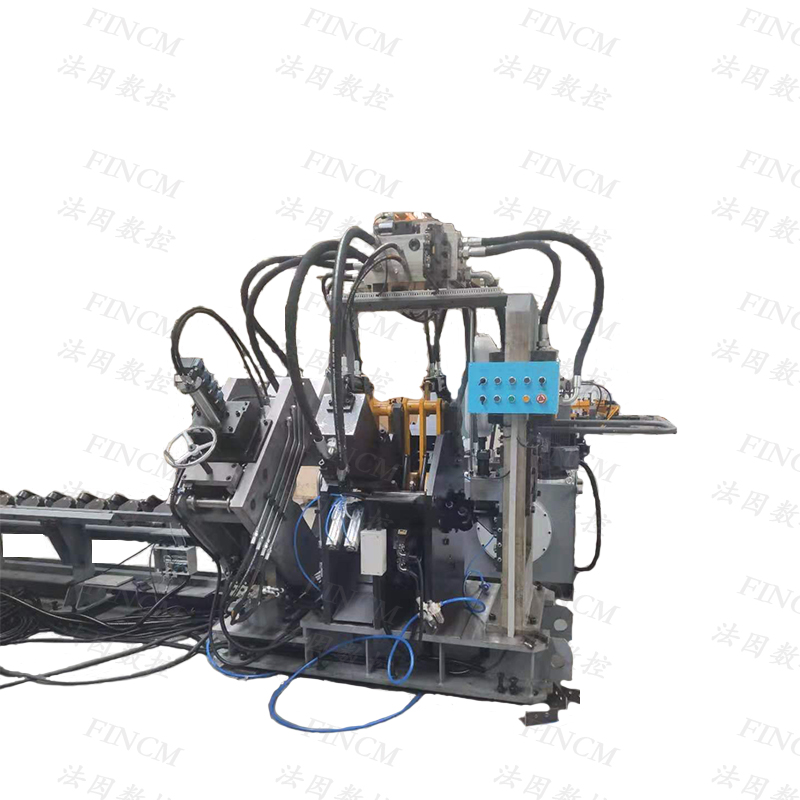

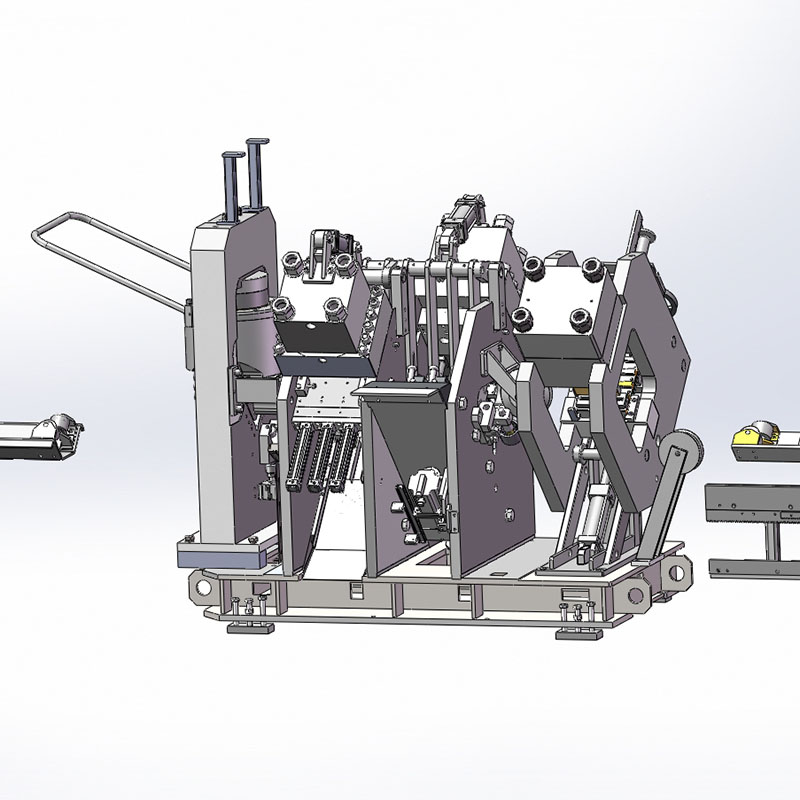

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for OEM/ODM Factory Metal CNC Milling Machine - CNC Drilling Shearing and Marking Machine for Angles Steel – FIN CNC , The product will supply to all over the world, such as: Argentina, Rome, Danish, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.