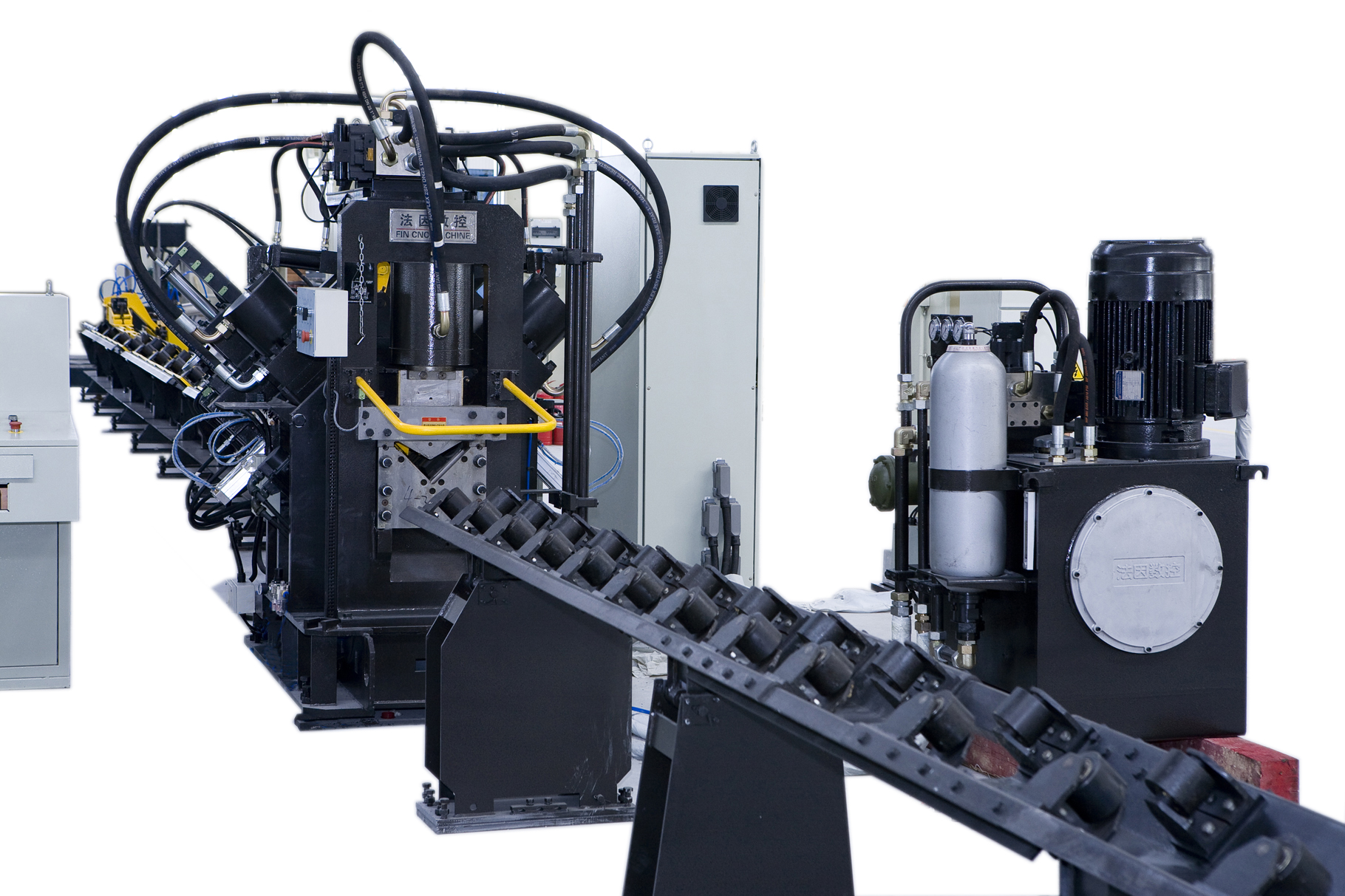

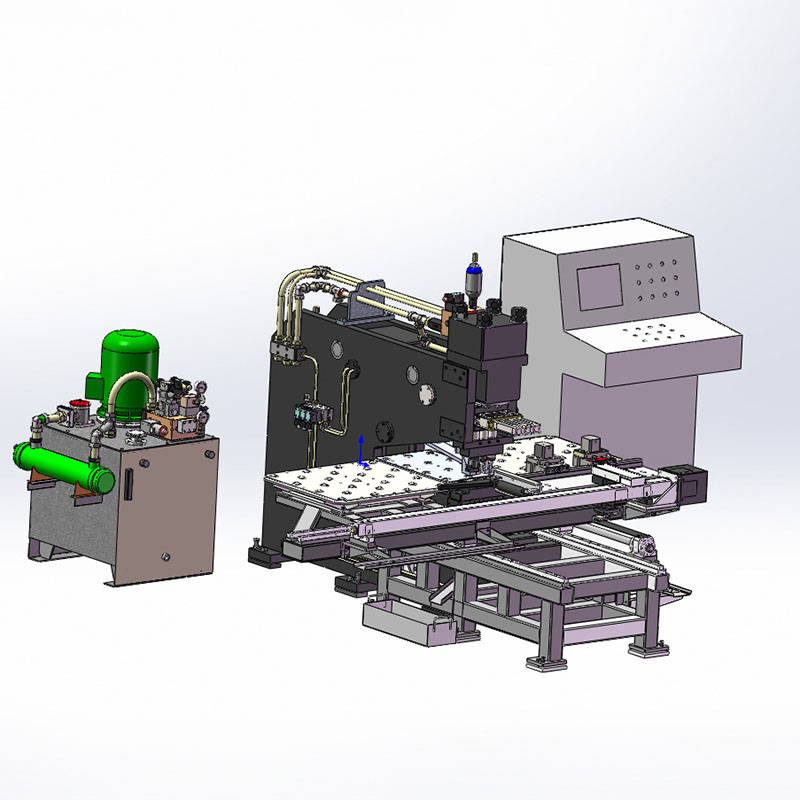

Quality Inspection for Metal Cutting Machine - BL1412 CNC Angle Steel Punching Shearing Machine – FIN CNC

Quality Inspection for Metal Cutting Machine - BL1412 CNC Angle Steel Punching Shearing Machine – FIN CNC Detail:

Product Parameters

| No. | Item | Parameters |

| 1 | Angle size | 10*10*3-140*140*12(Q345) |

| 2 | Max. punching diameter | φ25.5mm (12mm thickness, Q345) |

| 3 | Nominal punching force | 540KN |

| 4 | Nominal marking force | 750KN |

| 5 | Max. length of the raw angle | 12m |

| 6 | Quantity of punching head per side | 2 |

| 7 | The quantity of punching row per side | arbitrariness |

| 8 | Quantity of character group | 4 group |

| 9 | Dimension of characters | 14*10mm |

| 10 | Cutting mode | Double-blade cutting |

| 11 | Quantity of axes | 3 |

| 12 | In feeding speed | 40m/min |

| 13 | Overall dimension | 25.4×7×2.2m(Only for reference) |

| 14 | Layout | Type A or B |

Details and advantages

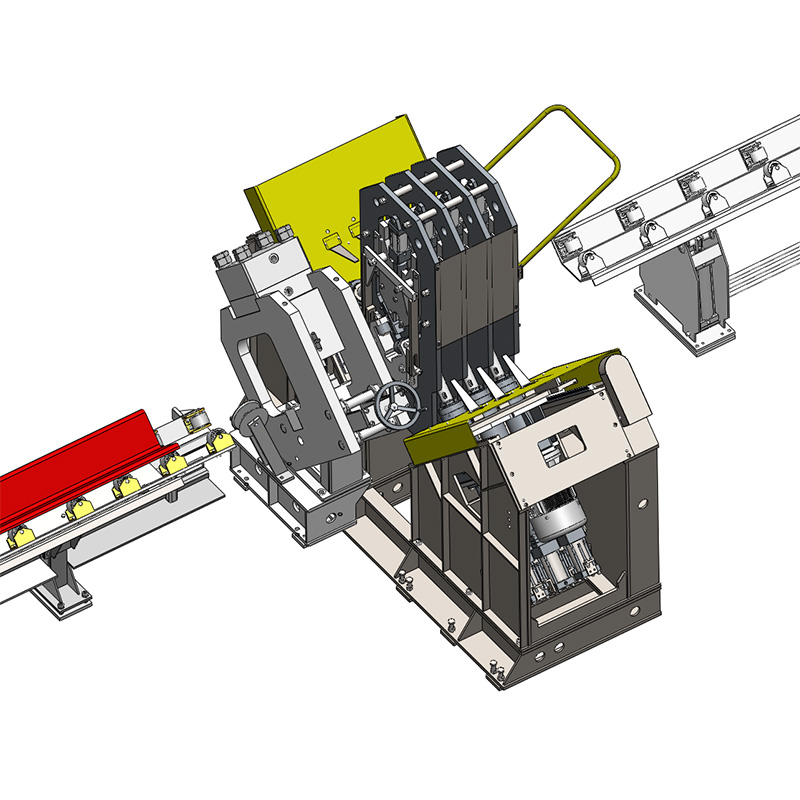

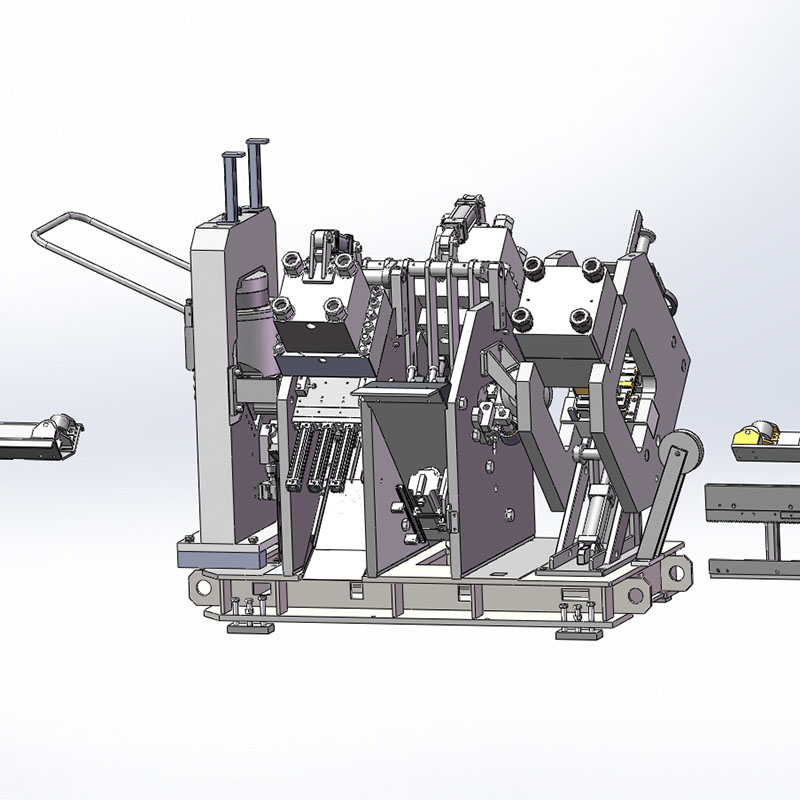

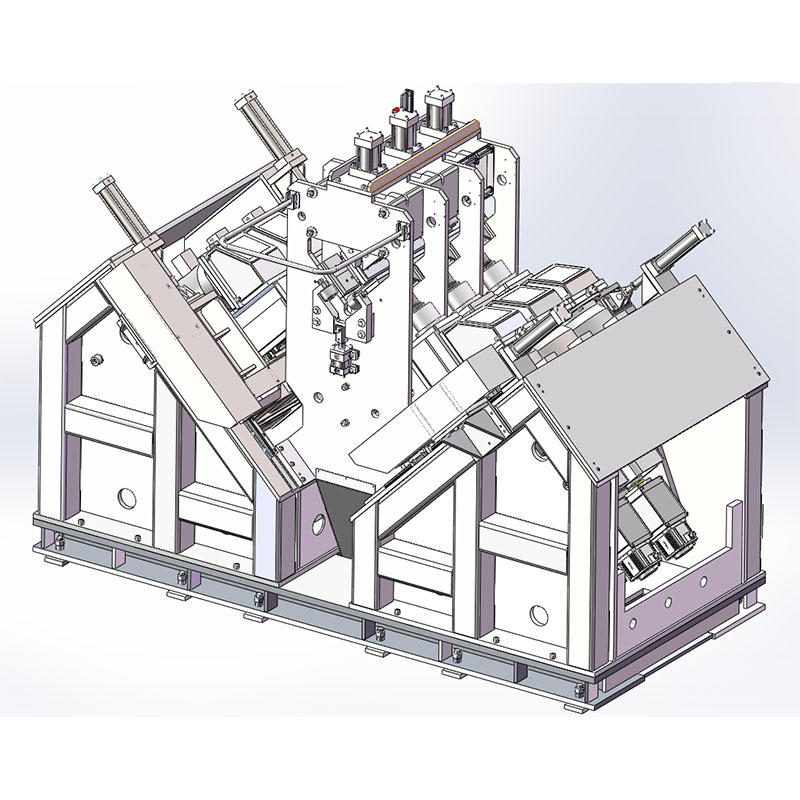

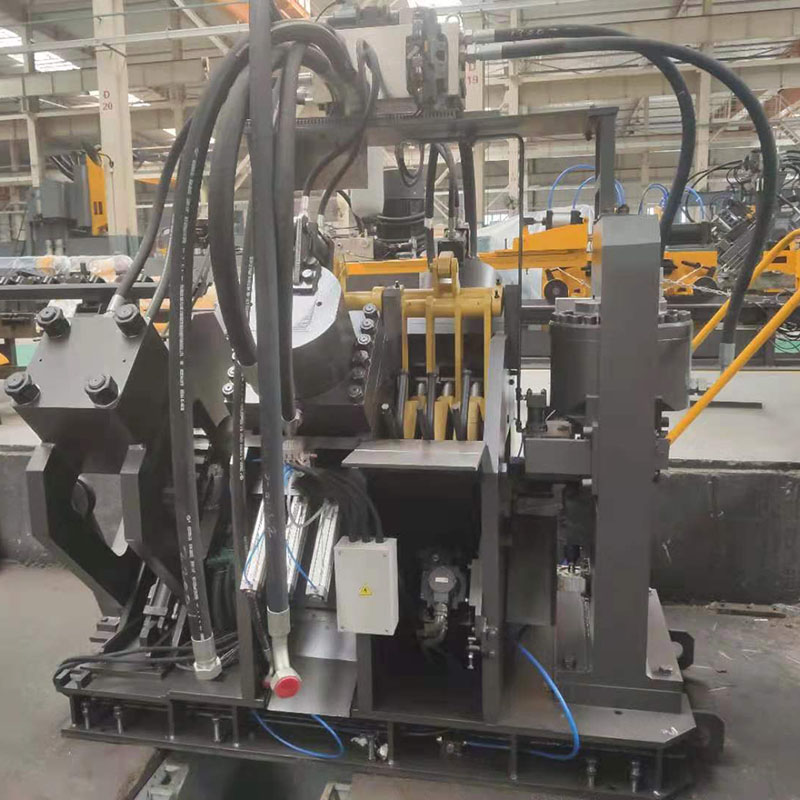

1. Punching unit adopts closed structure frame, which is very rigid.

2. The single blade cutting mechanism ensures that the cutting section is neat and the shearing clearance is easy to adjust.

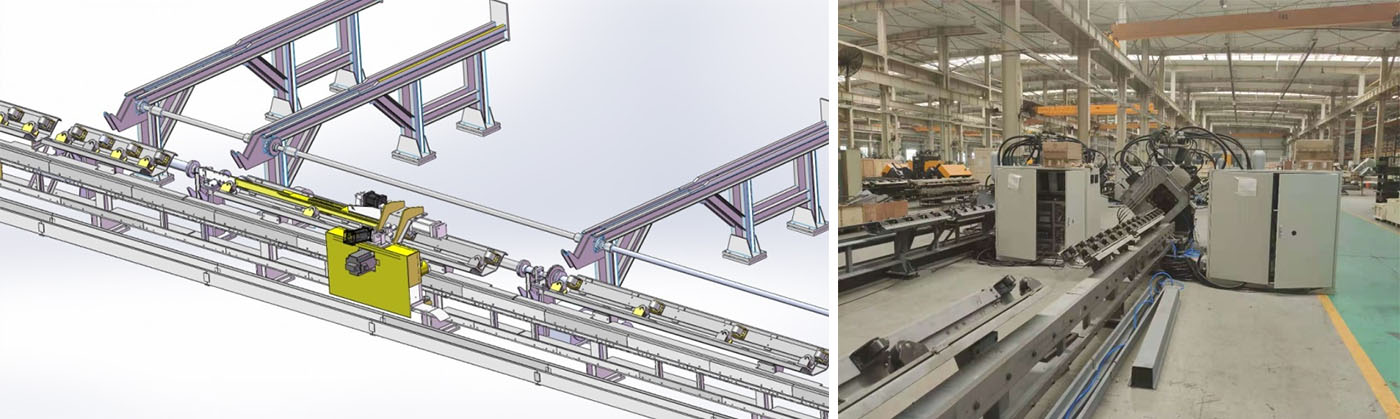

3. The CNC feeding trolley is clamped by pneumatic clamp to move and position rapidly. The angle is driven by servo motor, driven by rack and pinion and linear guide, with high positioning accuracy.

4. This machine has a CNC axis: the movement and positioning of the feeding This machine has a CNC axis: the movement and positioning of the feeding gripper carriage.

5. The hydraulic pipeline adopts the ferrule structure, which effectively reduces the oil leakage and improves the stability of the machine.

6. It is easy to program by computer. It can display the workpiece figure and the coordinate size of the hole position, so it is easy to check. It is very convenient to store and call the program, to display the graph, to diagnose the fault and to communicate with the computer.

Key Outsourced Components List

|

NO |

Name |

Brand |

Country |

|

1 |

AC servo motor |

Delta |

Taiwan, China |

|

2 |

PLC |

Delta |

|

|

3 |

Double vane pump |

Albert |

USA |

|

4 |

Electromagnetic unloading valve |

ATOS/Yuken |

Italy / Taiwan, China |

|

5 |

Relief valve |

ATOS/Yuken |

|

|

6 |

Electromagnetic relief valve |

ATOS/Yuken |

|

|

7 |

Electro hydraulic directional valve |

JUSTMARK |

Taiwan, China |

|

8 |

Electromagnetic directional valve |

JUSTMARK |

|

|

9 |

Check valve |

JUSTMARK |

|

|

10 |

Air valve |

AirTAC |

|

|

11 |

Bus bar |

AirTAC |

|

|

12 |

Air value |

AirTAC |

|

|

13 |

Cylinder |

SMC/CKD |

Japan |

|

14 |

Duplex |

SMC/ CKD |

|

|

15 |

Computer |

lenovo |

China |

Product detail pictures:

Related Product Guide:

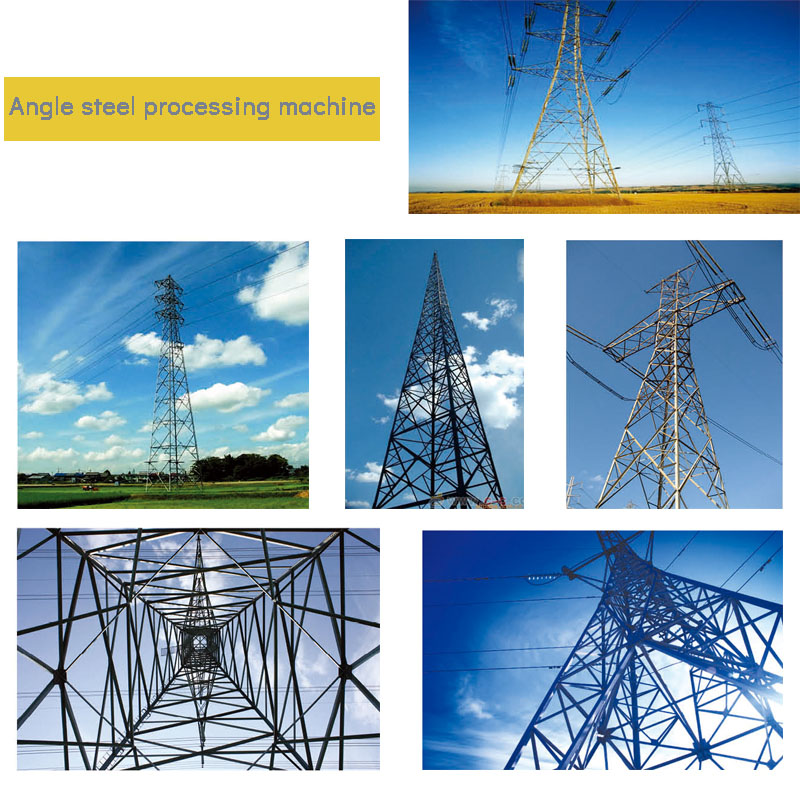

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for Quality Inspection for Metal Cutting Machine - BL1412 CNC Angle Steel Punching Shearing Machine – FIN CNC , The product will supply to all over the world, such as: Mozambique, Holland, Netherlands, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products and solutions for our customers.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.