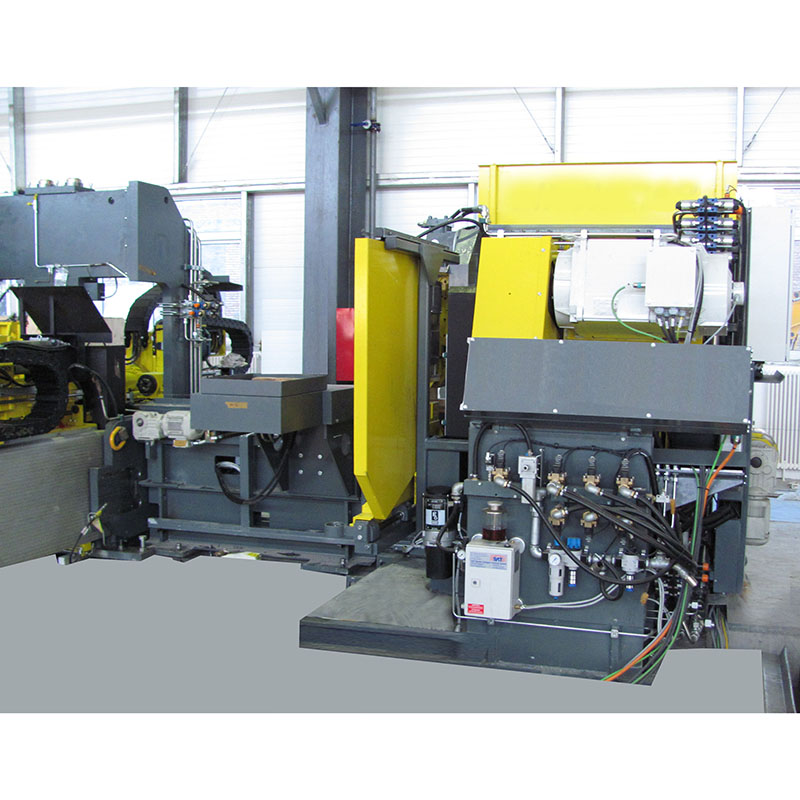

RDS13 CNC Rail Saw and Drill Combined Production Line

| Item | parameter | Specification |

| Basic rail model | Material type | 50Kg/m, 60 Kg/m, 75 Kg/m

hardness 340~400HB |

| Alloy steel core rail, alloy steel insert, hardness 38 HRC~45 HRC | ||

| Rail size | Raw material length | 2000~1250mm |

| Processing requirements | Material length | 1300~800mm |

| Material length tolerance | ±1mm | |

| End face perpendicularity | <0.5mm | |

| Drilling diameter | φ31~φ60mm | |

| Hole diameter tolerance | 0~0.5mm | |

| Hole height range | 60~100mm | |

| Main technical parameters of machine | Sawing method | Circular saw (high speed) |

| Spindle motor power | 37kW | |

| Saw blade diameter | Φ660mm | |

| Max moving speed of X axis | 25m/min | |

| Maximum moving speed of Z axis | 6m/min | |

| Drilling spindle type | BT50 | |

| Drilling Spindle speed | 3000r/min | |

| Drilling Spindle servo motor power | 37kW | |

| Maximum moving speed of X, Y, Z axis | 12m/min | |

| Chamfering spindle type | NT40 | |

| Chamfering spindle RPM Max. | 1000 | |

| Chamfering spindle motor power | 2.2 kW | |

| Movement speed of Y2 axis and Z2 axis | 10m/min | |

| Electric permanent magnetic chuck | 250×200×140mm(another200×200×140mm) |

|

| Work suction | ≥250N/cm² | |

| Chip removal system | 2set | |

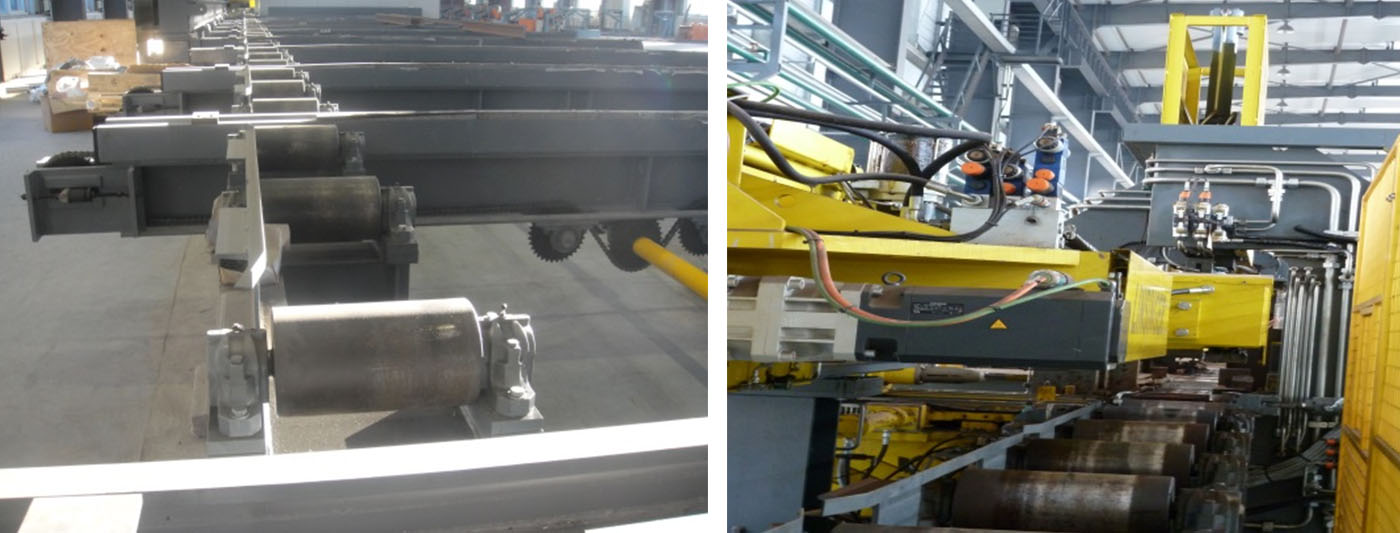

| Chip conveyor type | Flat chain | |

| Chip removal speed | 2m/min | |

| CNC system | Siemens828D | |

| Number of CNC systems | 2set | |

| Number of CNC axes | 6+1axis, 2+1axis | |

| Height of worktable | 700mm | |

| Height of worktable | about 37.8m×8m×3.4m |

1. There is a saw blade chip removal device on the sawing unit, which is responsible for removing sawdust from the saw blade. The cooling and lubricating device lubricates and cools the sawing area, which improves the service life of the saw blade.guide rails, and the mobile column is installed on the machine bed.

2. Coding system

The coding system is installed on the outer side of the power head ram, and is equipped with a host computer to program and control the coding system.

3. Drilling unit

The column structure is adopted, and the column adopts a steel plate welded structure. After annealing and artificial aging treatment, the stability of the processing accuracy is ensured.

4. Drilling headstock

The drilling headstock is a ram type structure with strong rigidity. The timing belt has high tensile strength, long life, low noise and low vibration when running at high speed. The precision spindle is internally cooled and hollow, and is equipped with a 45° four-petal claw broach mechanism. The back end of the precision spindle is equipped with a hydraulic punching cylinder for easy tool replacement.

5. Workbench

Workbench adopts steel plate welding structure, pre-treatment is carried out before welding, and after welding, stress relief and thermal aging treatment are carried out to ensure accuracy and stability.

6. Chip removal system

The automatic chip conveyor is a flat chain type, with a total of two sets. One set is used for the sawing unit and is placed under the side of the saw blade. The other set is used for the drilling unit, which is placed between the bed and the workbench. The iron filings fall on the chip conveyor via the chip guide on the workbench, and the iron filings are transported to the iron filing box at the head through the chip conveyor.

7. Lubrication system

There are two sets of centralized automatic lubrication systems, one for the sawing unit and the other for the drilling unit. The automatic lubrication system performs intermittent lubrication on the linear rolling guide pair, ball screw pair, and rack and pinion pair to ensure their accuracy and service life.

8. Electrical system

The electrical system adopts Siemens 828D numerical control system, a total of two sets, one set is used to control the sawing unit, the horizontal feeding rack, the feeding roller table and the middle roller table. The other set is used to control the drilling unit, the workbench 1, the horizontal unloading rack and the workbench.

|

NO. |

Item |

Brand |

Origin |

|

1 |

Linear guide pair |

HIWIN |

Taiwan, China |

|

2 |

CNC system 828D |

Siemens |

Germany |

|

3 |

Servo motor |

Siemens |

Germany |

|

4 |

Coding system |

LDMinkjet printer |

Shanghai ,China |

|

5 |

Hydraulic oil pump |

Justmark |

Taiwan, China |

|

6 |

Drag chain |

CPS |

South Korea |

|

7 |

Gears, racks |

APEX |

Taiwan, China |

|

8 |

Precision reducer |

APEX |

Taiwan, China |

|

9 |

Precision spindle |

KENTURN |

Taiwan, China |

|

10 |

Main electrical components |

Schneider |

France |

Note: The above is our standard supplier. It's subject to be replaced by same quality components of other brand if the above supplier can't supply the components in case of any special matter.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability