Trending Products Sheet Metal Punching Machine - Hydraulic Angle Notching Machine – FIN CNC

Trending Products Sheet Metal Punching Machine - Hydraulic Angle Notching Machine – FIN CNC Detail:

Product Parameters

| No. | Item | Parameter | |

| ACH140 | ACH200 | ||

| 1 | Nominal force | 560 KN | 1000KN |

| 2 | Rated pressure of hydraulic system | 22Mpa | |

| 3 | Number of no-load running | 20 times/min | |

| 4 | Single blade cutting |

140*140*16mm (material Q235-A, Max. Tensile Strengthσb≈410MPa) |

200*200*20mm (material Q235-A, Max. Tensile Strengthσb≈410MPa) |

| 5 | 140*140*14mm (material 16Mn, Max. Tensile Strengthσb≈600MPa) |

||

| 6 | 140*140*12mm (material Q420, Max. Tensile Strengthσb≈680MPa) |

200*200*16mm (material Q420, Max. Tensile Strengthσb≈680MPa) |

|

| 7 | Shearing angle | 0°~45° | |

| 8 | Maximum cutting length | 200 mm | 300mm |

| 9 | Square angle cutting |

140*140*12mm(Q235-A, Maximum tensile strengthσb≈410MPa) | 200*200*16mm(Q235-A, Maximum tensile strengthσb≈410MPa) |

| 10 | 140*140*10mm(16Mn, Maximum tensile strengthσb≈600MPa) | 200*200*12mm(16Mn, Maximum tensile strengthσb≈600MPa) | |

| 11 | Ambient temperature | 0℃~40℃ | |

| 12 | Motor power of hydraulic pump | 15KW | 18.5KW |

| 13 | Machine overall size (L*W*H) |

2000*1100*1850mm | 2635*1200*2090MM |

| 14 | Machine weight | About 3000kg | About 6500kg |

Details and advantages

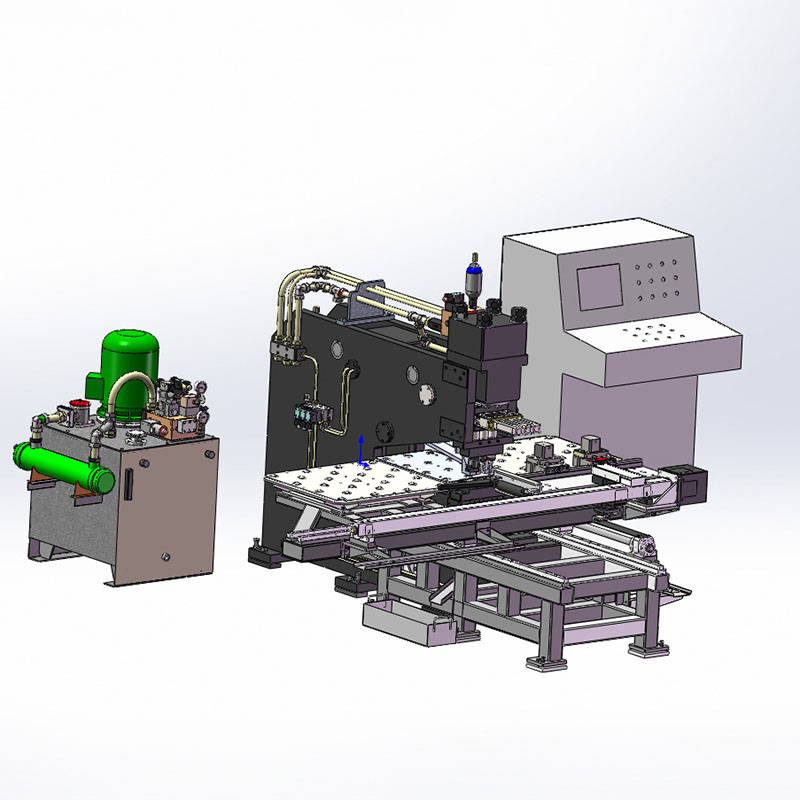

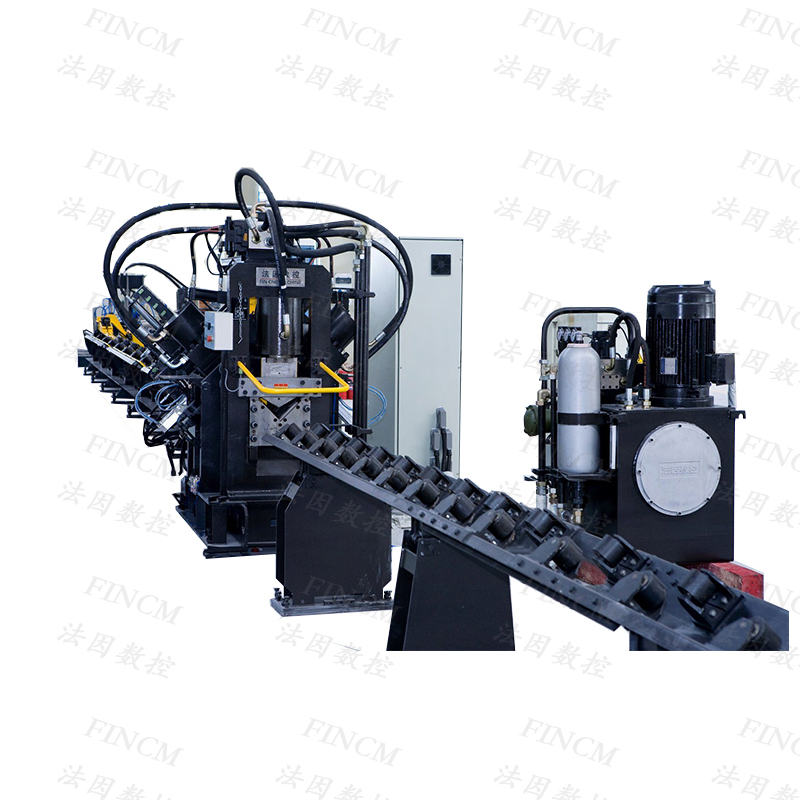

This product is composed of a main machine, cutting mould, and a hydraulic station, and is equipped with an electrical system to fulfill angle cutting.

1. Main machine

The main machine is welded by steel plates in a C shape. The upper part is the oil cylinder, and the lower part is the working table, which provides support for the mould and meets the strength and rigidity requirements of the machine.

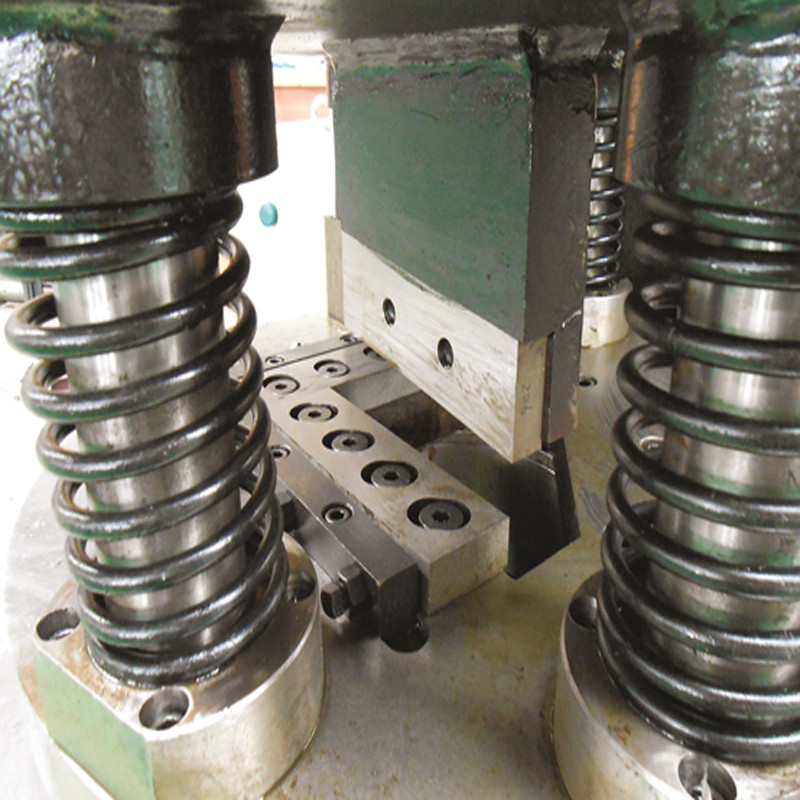

2. Mould

The mould part is guided by sliding rails, this structure bears large partial loads and has high guiding accuracy.

3. Hydraulic station

The hydraulic system is composed of oil tank, motor, high and low pressure pump, control valve, oil filter shearing cylinder, etc. It is the power source of shearing cylinder. The electromagnetic reversing valve, overflow valve, unloading valve, etc. are imported parts with reliable performance and long service life.

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of Trending Products Sheet Metal Punching Machine - Hydraulic Angle Notching Machine – FIN CNC , The product will supply to all over the world, such as: Irish, Sydney, Surabaya, Our solutions have national accreditation standards for experienced, premium quality goods, affordable value, was welcomed by people around the globe. Our products will continue to increase in the order and look forward to cooperation with you, Truly must any of people goods be of interest to you, make sure you letus know. We're likely to be delighted to give you a quotation up on receipt of one's in depth specs.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!