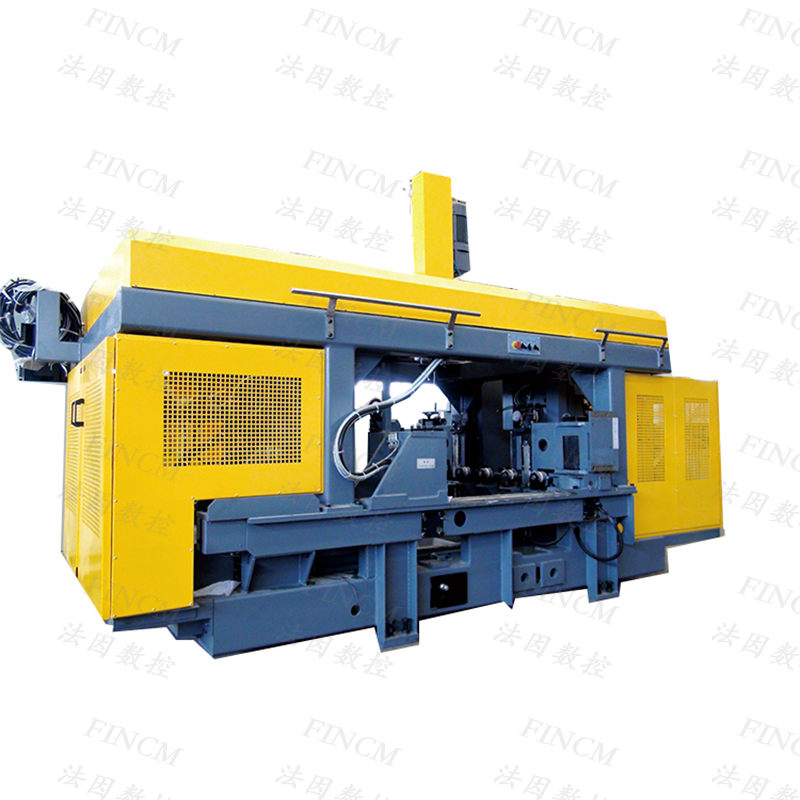

Professional China Angle Bending - SWZ1250C FINCM Structure Drilling H-Beam Processing Machine – FIN CNC

Professional China Angle Bending - SWZ1250C FINCM Structure Drilling H-Beam Processing Machine – FIN CNC Detail:

Product parameters

|

NO. |

Parameter name |

Unit |

Parameter value |

Remark |

||

|

1 |

Section steel |

mm |

150×75~1250×600 |

|

||

|

2 |

Thickness |

mm |

≤80 |

|

||

|

3 |

Length |

m |

15m |

Configure according to customer demand | ||

|

4 |

Short material limit |

mm |

Automatic processing≥3000 |

|

||

|

Manual processing:690~3000 |

||||||

|

6 |

Quantity |

|

3 |

|

||

|

7 |

drill hole Range |

Fixed side, mobile side |

mm |

¢12~¢26.5 |

|

|

|

Intermediate unit |

mm |

¢12~¢33.5 |

|

|||

|

9 |

Spindle speed |

r/min |

180~560 |

|

||

|

10 |

Change the card head quickly |

/ |

Morse taper hole 3#、、4# |

Can change to 2# |

||

|

11 |

Axial stroke |

Fixed side, mobile side |

mm |

140 |

|

|

|

Intermediate unit |

mm |

240 |

|

|||

|

12 |

Axial feed rate |

mm/min |

20~300 |

|

||

|

13 |

Moving distance |

Each spindle is in the direction of workpiece length |

mm |

520 |

|

|

|

Both sides of the spindle in the up and down direction |

mm |

35~570 |

From the lower plane of the workpiece |

|||

|

The intermediate unit is in the direction of workpiece width |

mm |

45~1160 |

From the datum side |

|||

|

14 |

Compressed air + cutting fluid |

/ |

/ |

|

||

|

15 |

Air pressure |

Mpa |

≥0.5 |

|||

|

16 |

Error of adjacent hole spacing in hole group |

mm |

≤0.5 |

|

||

|

17 |

Feeding error within 10 m length |

mm |

≤1 |

|

||

|

18 |

Fuel tank capacity |

L | 50 |

|

||

|

19 |

Distance error of adjacent holes in hole group |

mm |

≤±0.5 |

|

||

|

20 |

Accuracy of adjacent feeding distance within 10 meters |

mm |

≤±1 |

|

||

|

21 |

Three phase asynchronous motor for spindle rotation |

kW |

4×3 |

Number of spindles 3 |

||

|

22 |

Intermediate unit X-axis servo motor |

kW |

0.85 |

|

||

|

23 |

Z-axis servo motor of intermediate unit |

kW |

1.3 |

|

||

|

24 |

Fixed side and mobile side X-axis servo motor |

kW |

0.85×2 |

|

||

|

25 |

Fixed side and mobile side Y-axis servo motor |

kW |

1.3×2 |

|

||

|

26 |

Moving carriage three phase asynchronous motor |

kW |

0.55 |

|

||

|

27 |

Over dimension |

mm |

About 4800×2400×3300 |

|

||

|

28 |

Weight |

kg |

About 7000 |

|

||

Details and advantages

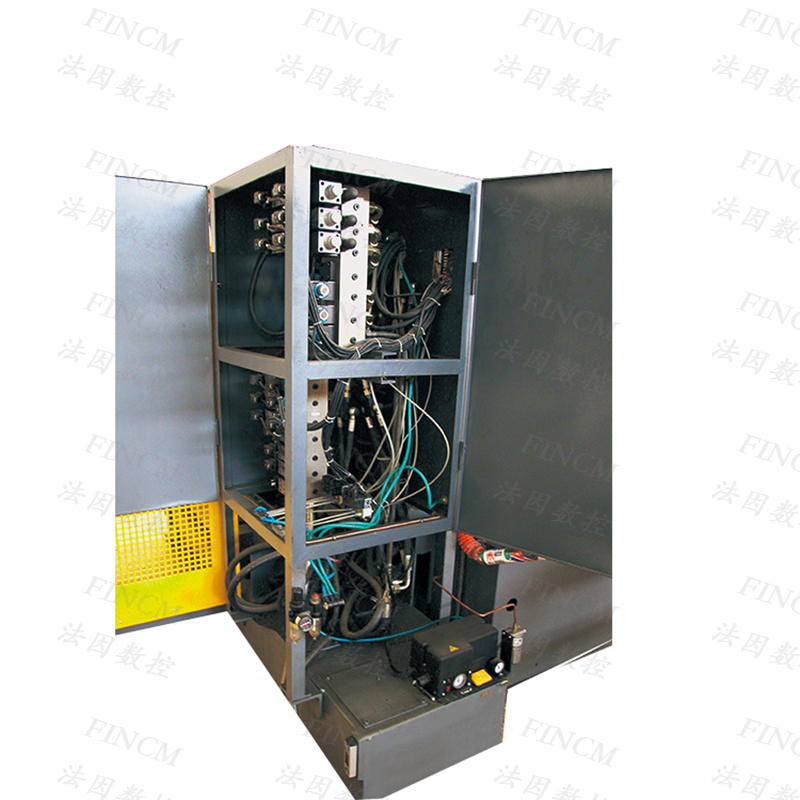

Electrical system

1). PLC is used to control the positioning of each CNC axis, material detection and drilling and other machine actions. The PLC control system realizes high-speed processing and improves the response speed of the system.

2). The CNC feeding device (feeding trolley) adopts full closed loop control to ensure the feeding accuracy during long-distance feeding; other positioning CNC axes adopt semi-closed loop control to ensure the positioning accuracy and stability of the machine tool.

3). Real-time monitoring function.

4). A variety of material programming methods.

5). Graphic display function.

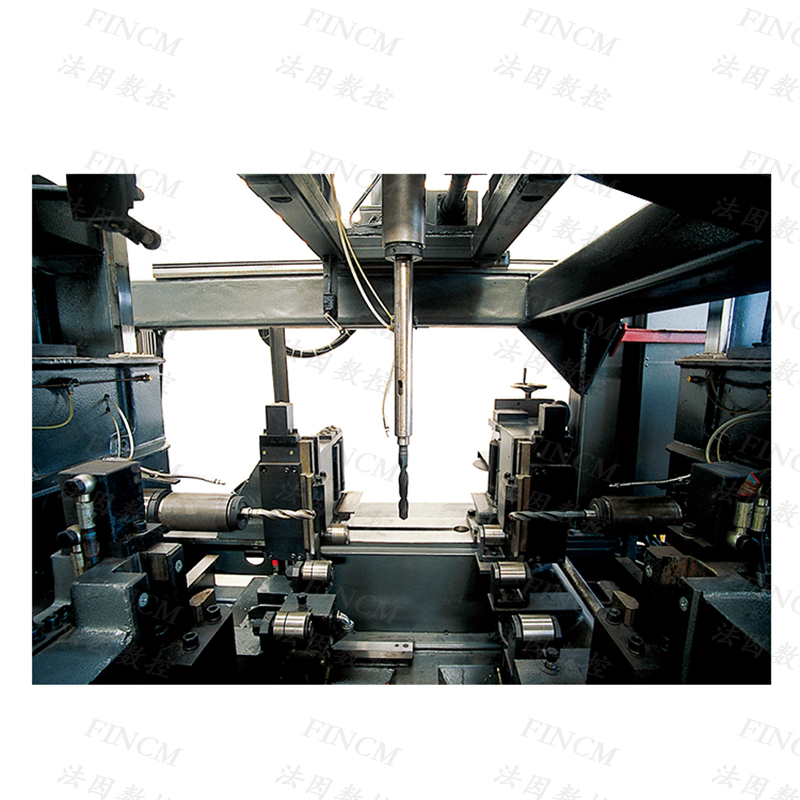

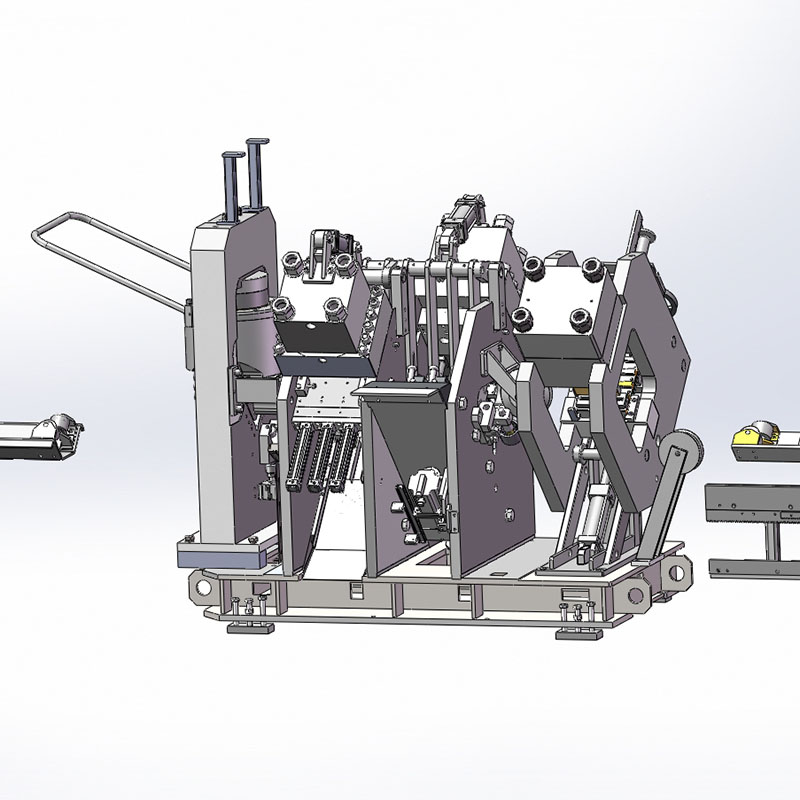

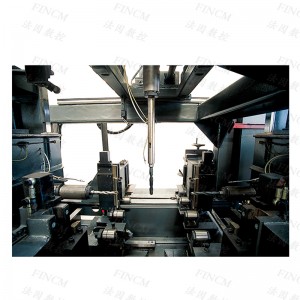

1. Three automatic control stroke drilling power heads are respectively installed on three NC slide blocks for horizontal and vertical drilling. The three drilling power heads can work independently or simultaneously.

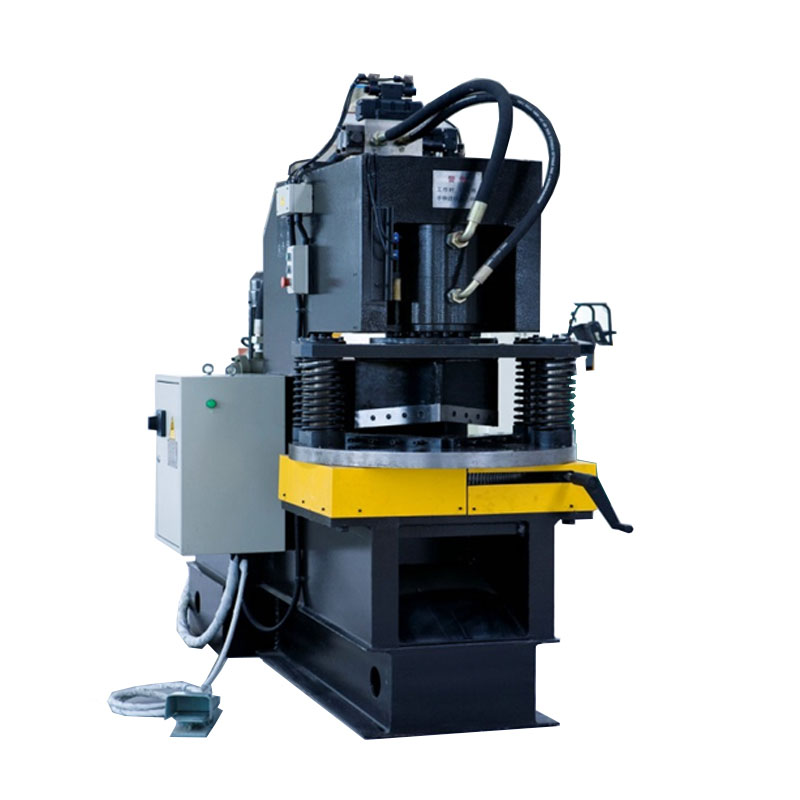

2. The spindle speed of each drilling power head is controlled by frequency converter and stepless adjusted; the feed speed is stepless adjusted by speed regulating valve, which can be adjusted rapidly in a large range according to the material of material and diameter of drilling hole.

3. The material is fixed by hydraulic clamping mechanism.

4. The machine is equipped with the detection device of the width of the material and the height of the web, which can automatically compensate the machining error caused by the irregular outline of the material, and improve the machining accuracy.

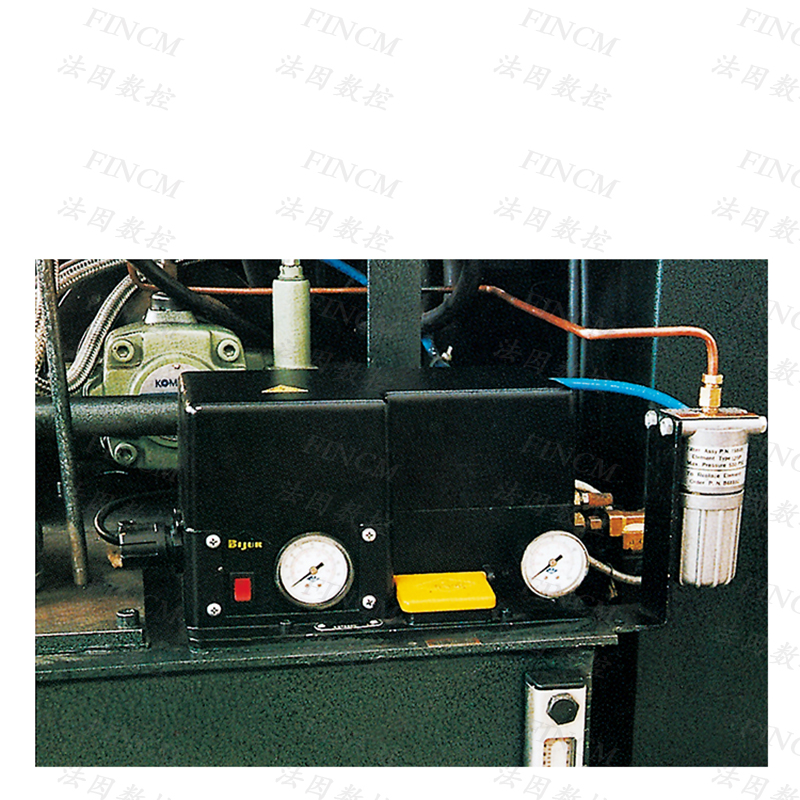

5. The machine is equipped with an aerosol cooling system, which has the advantages of less coolant consumption, cost saving and less bit wear.

Key outsourced components

|

NO. |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

HIWIN/CSK |

Taiwan (China) |

|

2 |

Electromagnetic hydraulic valve |

ATOS/YUKEN |

Italy/Japan |

|

3 |

Hydraulic pump |

Justmark |

Taiwan (China) |

|

4 |

Servo motor |

Panasonics |

Japan |

|

5 |

Servo driver |

Panasonics |

Japan |

|

6 |

PLC |

MITSUBISHI |

Japan |

|

7 |

Spray cooling pump |

BIJUR |

USA |

|

8 |

Flexible extension nozzle |

BIJUR |

USA |

|

9 |

Pneumatic solenoid valve |

AIRTAC |

Taiwan (China) |

|

10 |

Centralized lubrication |

HERG/BIJUR |

Japan/USA |

|

11 |

Computer |

Lenovo |

China |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter

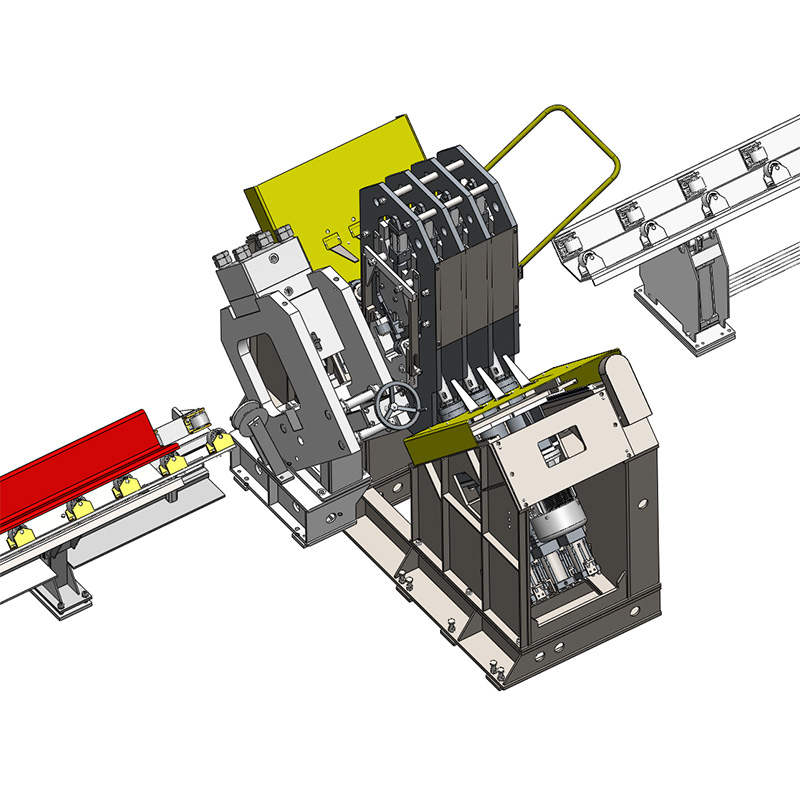

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for Professional China Angle Bending - SWZ1250C FINCM Structure Drilling H-Beam Processing Machine – FIN CNC , The product will supply to all over the world, such as: Switzerland, Chile, Peru, We welcome you to visit our company and factory. It is also convenient to visit our website. Our sales team will offer you the best service. If you need more information, please feel free to contact us by E-mail or telephone. We are sincerely hope to establish a good long-term business relationship with you through this opportunity, based on equal, mutual benefit from now till the future.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!