PEM Series Gantry mobile CNC mobile plane drilling machine

| Item | Name | Value | |||||||

| PEM3030-2 | PEM4040-2 | PPEM5050-2 | PEM6060-2 | ||||||

| Maximum Plate material Size | L x W | 3000*3000 mm | 4000*4000mm | 5000×5000 mm | 6000×6000 mm | ||||

| Maximum material Thickness | 250 mm (Can be expanded to 380mm) |

||||||||

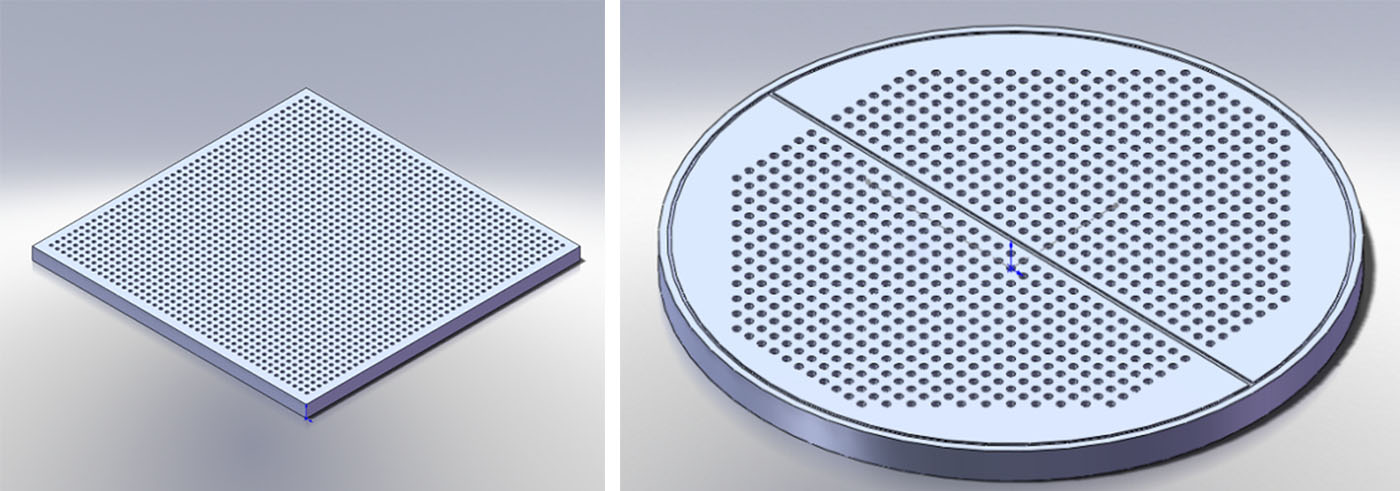

| Work Table | T Slot Width | 28 mm(standard) | |||||||

| Loading Weight | 3ton/ | ||||||||

| Drilling Spindle | Maximum Drilling Diameter | Φ50 mm | |||||||

| Drilling spindle’s Rod Length & Hole diameter | ≤10 | ||||||||

| Spindle Tape | BT50 | ||||||||

| Spindle motor power | 2*18.5kw/22kw | ||||||||

| Distance from Spindle bottom surface to the worktable | 280~780 mm (adjustable as per material thickness) |

||||||||

| Positioning accuracy | X axis, Y axis | 0.06mm/ full stroke |

0.10mm/ full stroke |

0.12mm/ full stroke |

|||||

| Repeatable positioning accuracy | X axis, Y axis | 0.035mm/full stroke | 0.04mm/full stroke | 0.05mm/full travel | 0.06mm/full travel | ||||

| Hydraulic system | Hydraulic pump pressure/ Flow rate |

15MPa /22L/min | |||||||

| Hydraulic pump motor power | 3 kW | ||||||||

| Pneumatic system | Compressed air pressure | 0.5 MPa | |||||||

| Chip removal and Cooling system | Chip removal type | Plate chain | |||||||

| Chip removal Number | 2 | ||||||||

| Chip removal speed | 1m/min | ||||||||

| Motor Power | 2×0.75kW | ||||||||

| Cooling way | Inner cooling + Outside cooling | ||||||||

| Max. Pressure | 2MPa | ||||||||

| Max. Flow rate | 2*50L/min | ||||||||

| Electronic system | CNC system | KND2000 | |||||||

| CNC Axis Number | 6 | ||||||||

| Total power | About 70kW | ||||||||

| Overall Dimension | L×W×H | About 7.8*6.7*4.1m | About 8.8*7.7*1.1m |

About 9.8×7.7×4.1m | About 10.8×9.7×4.1m | ||||

| Machine weight | About 22Tons | About 30Tons | About 35tons | About 45tons | |||||

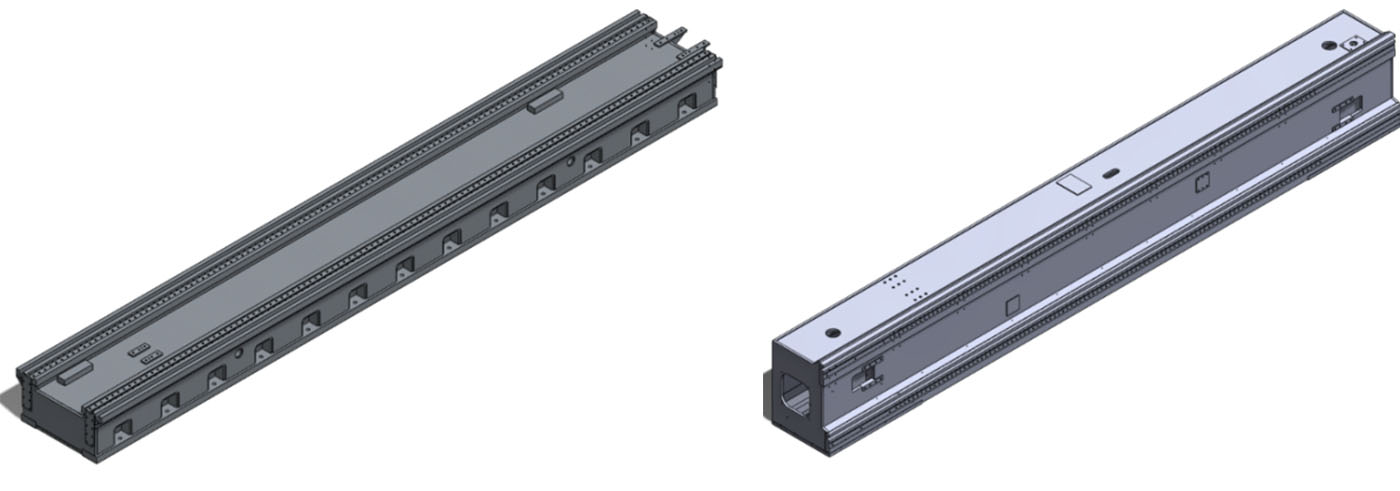

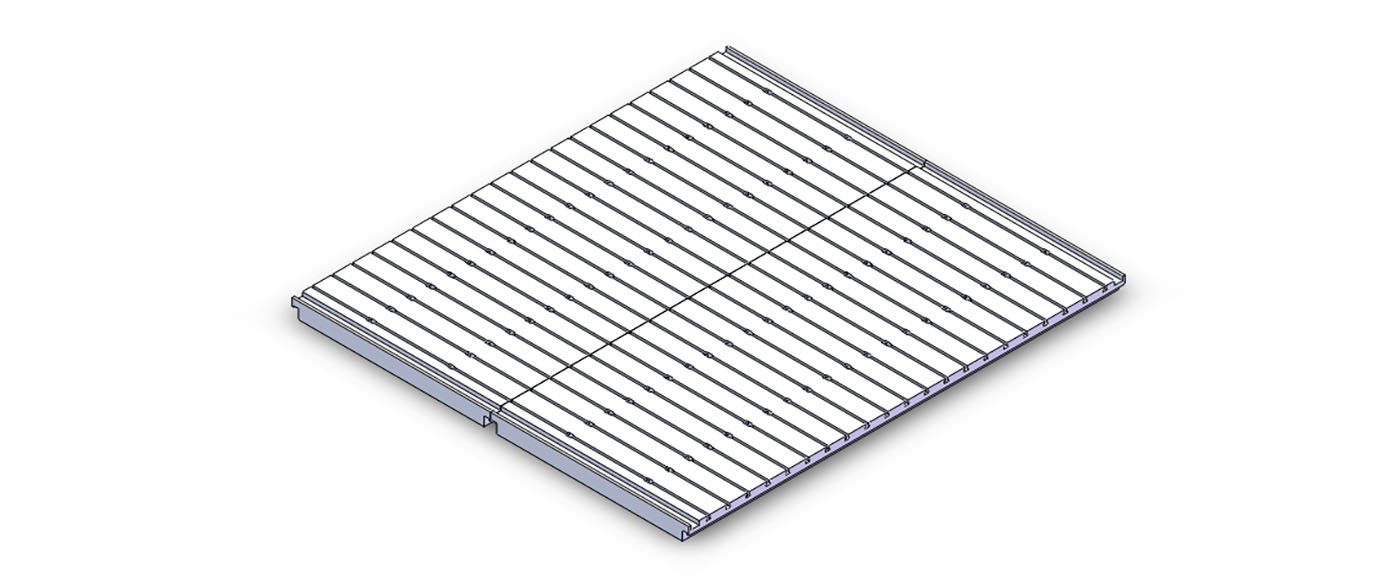

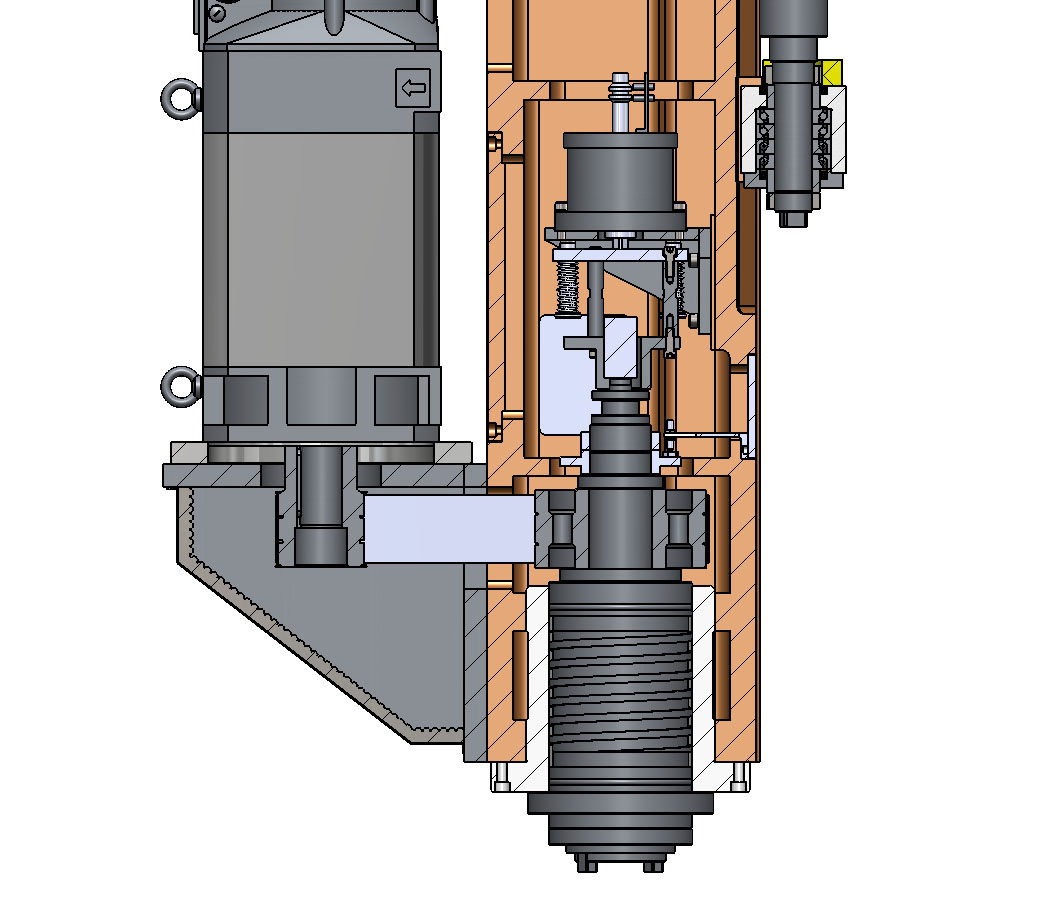

1. This machine is mainly composed of bed and column, beam and horizontal sliding table, vertical ram type drilling power box, worktable, chip conveyor, hydraulic system, pneumatic system, cooling system, centralized lubrication system, electrical system, etc.

2. High-rigidity bearing seat, the bearing adopts high-precision screw. The extra-long mounting base surface ensures axial rigidity. The bearing is pre-tightened by a lock nut, and the lead screw is pre-tensioned. The stretching amount is determined according to the thermal deformation and elongation of the lead screw to ensure that the positioning accuracy of the lead screw does not change after the temperature rises.

3. The vertical (Z-axis) movement of the power head is guided by a pair of linear roller guides arranged on the ram, with good guide precision, high vibration resistance and low friction coefficient. The ball screw drive is driven by a servo motor through a precision planetary reducer, which has a high feed force.

4. This machine adopts two flat chain chip conveyors on both sides of the worktable. Iron chips and coolant are collected in the chip conveyor, and the iron chips are transported to the chip conveyor, which is very convenient for chip removal; the coolant is recycled.

5. This machine provides two cooling methods—internal cooling and external cooling, which provide sufficient lubrication and cooling to the tool and material during chip cutting, which better guarantees the processing quality. The cooling box is equipped with liquid level detection and alarm components, and the standard cooling pressure is 2MPa.

6. The X-axis guide rails on both sides of the machine are equipped with stainless steel protective covers, and the Y-axis guide rails are equipped with flexible protective covers at both ends.

7. This machine is also equipped with a photoelectric edge finder to facilitate the positioning of circular material.

|

NO. |

ITEM |

BRAND |

Origin |

| 1 |

Roller linear guide rail |

HIWIN /CSK |

China Taiwan |

| 2 |

CNC control system |

SIEMENS |

Germany |

| 3 |

Feeding servo motor and servo driver |

SIEMENS |

Germany |

| 4 |

Precise spindle |

SPINTECH/KENTURN |

China Taiwan |

| 5 |

Hydraulic valve |

YUKEN /JUSTMARK |

Japan/ China Taiwan |

| 6 |

Oil pump |

JUSTMARK |

China Taiwan |

| 7 |

Automatic lubricating system |

HERG |

Japan |

Note: The above is our standard supplier. It's subject to be replaced by same quality components of other brand if the above supplier can't supply the components in case of any special matter.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability