PLM4020 Gantry Movable CNC Plate Drilling Machine Machine

(1) The machine frame body and cross beam are in welded fabricated structure, after enough aging heat treatment, with very good accuracy. The work table, transversal sliding table and ram all are made from cast iron.

(2) Two sides' dual servo driving system at X axis assures the gantry's parallel accurate movement, and the good squareness of Y axis and X axis.

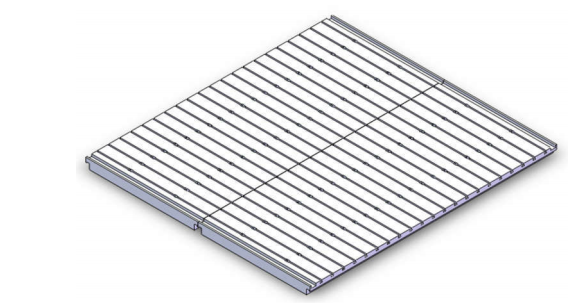

(3) The worktable adopts fixed form, high-quality cast iron and advanced casting process, with large bearing capacity.

(4) High rigidity bearing seat, bearing adopts back-to-back installation method, special bearing with high precision screw.

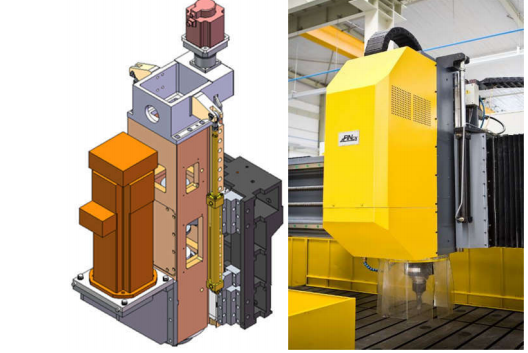

(5) The vertical (Z-axis) movement of the power head is guided by roller linear guide pairs arranged on both sides of the ram, which has good precision, high vibration resistance and low friction coefficient.

(6) The drilling power box belongs to rigid precision spindle type, which adopts Taiwan BT50 internal cooling spindle. The spindle cone hole has a purging device, and can use cemented carbide internal cooling drill, with high precision. The spindle is driven by high-power spindle servo motor through synchronous belt, the reduction ratio is 2.0, the spindle speed is 30~3000r/min, and the speed range is wide.

(7) The machine adopts two flat chain chip removers on both sides of the worktable. The iron chips and coolant are collected in the chip remover. The iron chips are transported to the chip carrier, which is very convenient for chip removal. The coolant is recycled.

(8) The machine provides two kinds of cooling methods - internal cooling and external cooling. The high pressure water pump is used to supply the coolant needed for internal cooling, with high pressure and large flow.

(9) The machine is equipped with an automatic lubrication system, which pumps the lubricating oil into the linear guide pair sliding block, ball screw pair screw nut and rolling bearing of each part regularly to carry out the most sufficient and reliable lubrication.

(10) The X-axis guide rails on both sides of the machine are equipped with stainless steel protective covers, and the Y-axis guide rails are installed with flexible protective covers.

(11) The machine tool is also equipped with a photoelectric edge finder to facilitate the positioning of round workpieces.

(12) The machine tool is designed and installed with complete safety facilities. The gantry beam is equipped with a walking platform, guardrail, and a climbing ladder on the side of the column to ensure the safety of operation and maintenance personnel. A transparent soft PVC strip cover is installed around the main shaft.

(13) The CNC system is equipped with Siemens 808D or Fagor 8055, which has powerful functions. The operation interface has the functions of man-machine dialogue, error compensation and automatic alarm. The system is equipped with electronic handwheel, which is easy to operate. Equipped with a portable computer, the CAD-CAM automatic programming can be realized after the upper computer software is installed.

| Item | Name | Value |

|---|---|---|

| Maximum Plate Size | L x W | 4000×2000 mm |

| Maximum Plate Size | Diameter | Φ2000mm |

| Maximum Plate Size | Maximum Thickness | 200 mm |

| Work Table | T Slot Width | 28 mm(standard) |

| Work Table | Work table dimension | 4500x2000mm (LxW) |

| Work Table | Loading Weight | 3 ton/㎡ |

| Drilling Spindle | Maximum Drilling Diameter | Φ60 mm |

| Drilling Spindle | Maximum Tapping Diameter | M30 |

| Drilling Spindle | Drilling spindle’s Rod Length vs. Hole diameter | ≤10 |

| Drilling Spindle | RPM | 30~3000 r/min |

| Drilling Spindle | Spindle Tape type | BT50 |

| Drilling Spindle | Spindle motor power | 22kW |

| Drilling Spindle | Maximum Torque (n≤750r/min) | 280Nm |

| Drilling Spindle | Distance from Spindle bottom surface to the worktable | 280~780 mm (adjustable as per material thickness) |

| Gantry Longitudinal Movement (X Axis) | Max. Travel | 4000 mm |

| Gantry Longitudinal Movement (X Axis) | Movement speed along X axis | 0~10m/min |

| Gantry Longitudinal Movement (X Axis) | Servo motor power of X axis | 2×2.5kW |

| Spindle Transversal Movement (Y Axis) | Max. Travel | 2000mm |

| Spindle Transversal Movement (Y Axis) | Movement speed along Y axis | 0~10m/min |

| Spindle Transversal Movement (Y Axis) | Servo motor power of Y axis | 1.5kW |

| Spindle Feeding Movement (Z Axis) | Max. Travel | 500 mm |

| Spindle Feeding Movement (Z Axis) | Feeding speed of Z axis | 0~5m/min |

| Spindle Feeding Movement (Z Axis) | Servo motor power of Z axis | 2kW |

| Positioning accuracy | X axis、Y axis | 0.08/0.05mm/full travel |

| Repeatable positioning accuracy | X axis、Y axis | 0.04/0.025mm/full travel |

| Hydraulic system | Hydraulic pump pressure/Flow rate | 15MPa /25L/min |

| Hydraulic system | Hydraulic pump motor power | 3.0kW |

| Pneumatic system | Compressed air pressure | 0.5 MPa |

| Scrap removal and Cooling system | Scrap removal type | Plate chain |

| Scrap removal and Cooling system | Scrap removal Nos. | 2 |

| Scrap removal and Cooling system | Scrap removal speed | 1m/min |

| Scrap removal and Cooling system | Motor Power | 2×0.75kW |

| Scrap removal and Cooling system | Cooling way | Inner cooling + Outside cooling |

| Scrap removal and Cooling system | Max. Pressure | 2MPa |

| Scrap removal and Cooling system | Max. Flow rate | 50L/min |

| Electronic system | CNC control system | Siemens 808D |

| Electronic system | CNC Axis Nos. | 4 |

| Electronic system | Total power | About 35kW |

| Overall Dimension | L×W×H | About 10×7×3m |

| No. | Name | Brand | Country |

|---|---|---|---|

| 1 | Roller linear guide rail | Hiwin | China Taiwan |

| 2 | CNC control system | Siemens/ Fagor | Germany/Spain |

| 3 | Feeding servo motor and servo driver | Siemens/Panasonic | Germany/Japan |

| 4 | Precise spindle | Spintech/Kenturn | China Taiwan |

| 5 | Hydraulic valve | Yuken/Justmark | Japan/China Taiwan |

| 6 | Oil pump | Justmark | China Taiwan |

| 7 | Automatic lubricating system | Herg/BIJUR | Japan/American |

| 8 | Button, Indicator, low voltage electronic components | ABB/Schneider | Germany/France |

| No. | Name | Size | Qty. |

|---|---|---|---|

| 1 | Optical edge finder | 1 piece | |

| 2 | Inner hexagon wrench | 1 set | |

| 3 | Tool holder and pull stud | Φ40-BT50 | 1 piece |

| 4 | Tool holder and pull stud | Φ20-BT50 | 1 piece |

| 5 | Spare paints | – | 2 kegs |

1.Power supply: 3 phase 5 lines 380+10%V 50+1HZ

2.Compressed air pressure: 0.5MPa

3.Temperature: 0-40℃

4.Humidity: ≤75%