PHD2020C CNC Drilling Machine for Steel Plates

| Maximum machining material size | Diameter | φ2000mm |

| Plate | 2000 x 2000mm | |

| Maximum processed plate thickness | 100 mm | |

| workbench | T-groove width | 22 mm |

| Drilling power head | Maximum drilling diameter of high speed steel twist drill | φ50 mm |

| Maximum drilling diameter of cemented carbide drill | φ40 mm | |

| Maximum milling cutter diameter | φ20mm | |

| Spindle taper | BT50 | |

| Main motor power | 22kW | |

| Maximum spindle torquen≤750r/min | 280Nm | |

| Distance from lower end face of spindle to worktable | 250—600 mm | |

| Gantry longitudinal movement (x-axis) | Maximum Stroke | 2050 mm |

| X-axis moving speed | 0—8m/min | |

| X-axis servo motor power | About 2×1.5kW | |

| Lateral movement of power head (Y-axis) | Maximum stroke of power head | 2050mm |

| Y-axis servo motor power | About 1.5kW | |

| Feed motion of power head (Z axis) | Z-axis travel | 350 mm |

| Z-axis servo motor power | About 1.5 kW | |

| positioning accuracy | X-axis, Y-axis | 0.05mm |

| Repeat positioning accuracy | X-axis, Y-axis | 0.025mm |

| Pneumatic system | Required air supply pressure | ≥0.8MPa |

| Chip conveyor motor power | 0. 45kW | |

| Cooling | Internal cooling mode | air-mist cooling |

| External cooling mode | Circulating water cooling | |

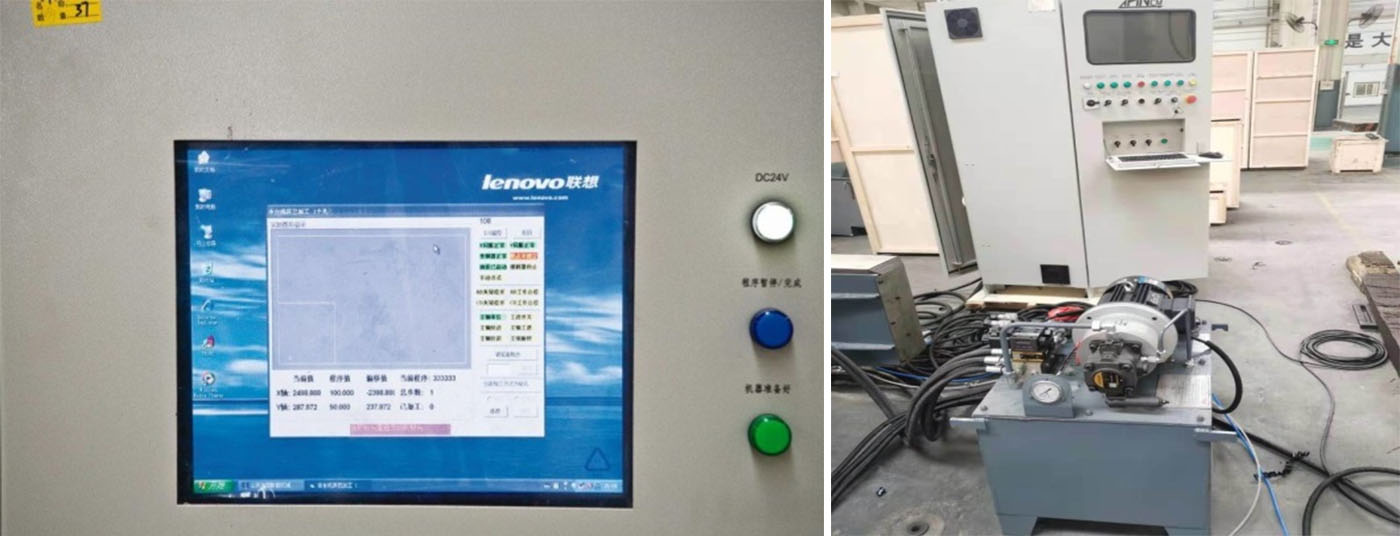

| Electrical system | CNC | Siemens 808D |

| Number of CNC axes | 4 | |

| Main Machine | Weight | About 8500kg |

| Overall dimension (L× W × H) | About 5300(3300)×3130×2830 mm |

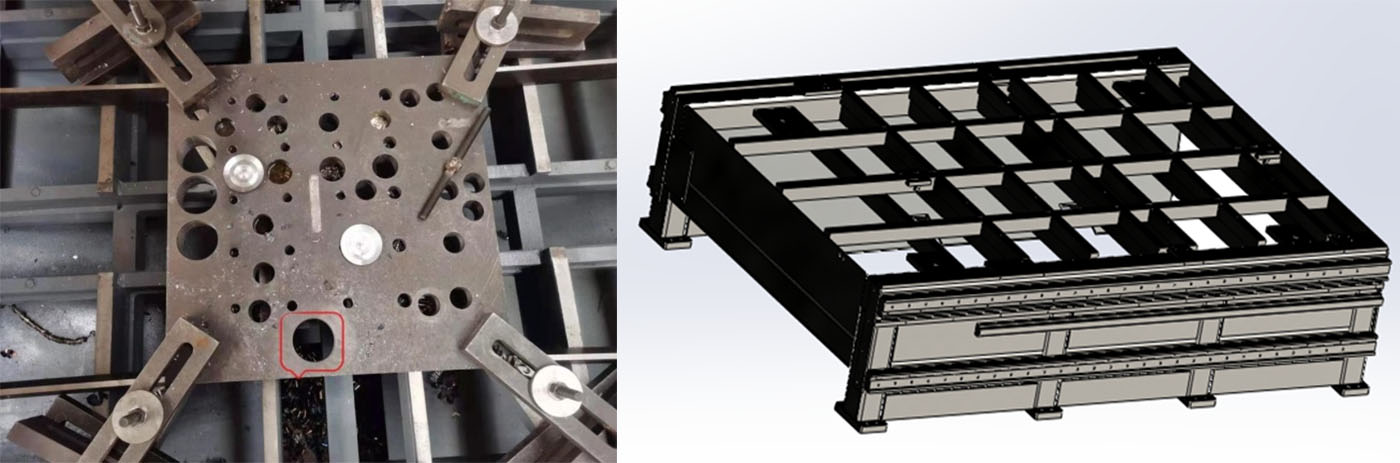

1. This machine mainly consists of bed and longitudinal slide plate, gantry and transverse slide table, drilling power head, chip removal device, pneumatic system, spray cooling system, centralized lubrication system, electrical system and etc.

2. The spindle of drilling power head adopts the precision spindle made in Taiwan, with high rotation precision and good rigidity. Equipped with BT50 taper hole, it is convenient to change tools. It can clamp both twist drill and cemented carbide drill, with a wide range of application. Small diameter end mills can be used for light milling. The spindle is driven by variable frequency motor, which has a wide range of applications.

3. The machine tool has four CNC axes: gantry positioning axis (x-axis, double drive); Transverse positioning axis (Y axis) of drilling power head; Drilling power head feed axis (Z axis). Each CNC axis is guided by precision linear rolling guide rail and driven by AC servo motor + ball screw.

4. The machine tool is equipped with a flat chain chip conveyor in the middle of the machine bed. The iron chips are collected into the chip conveyor, and the iron chips are transported to the chip conveyor, which is very convenient for chip removal; The coolant is recycled.

5. Flexible protective covers are installed on the x-axis and y-axis guide rails on both sides of the machine tool.

6. The cooling system has the effects of internal cooling and external cooling.

7. The CNC system of the machine tool is equipped with Siemens 808D and electronic hand wheel, which has powerful function and simple operation. It is equipped with RS232 interface and has the functions of processing preview and recheck. The operation interface has the functions of man-machine dialogue, error compensation and automatic alarm, and can realize the automatic programming of CAD-CAM.

|

NO. |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

HIWIN/PMI/ABBA |

Taiwan, China |

|

2 |

Ball screw pair |

HIWIN/PMI |

Taiwan, China |

|

3 |

CNC |

Siemens |

Germany |

|

4 |

servo motor |

Siemens |

Germany |

|

5 |

Servo driver |

Siemens |

Germany |

|

6 |

Precision spindle |

KENTURN |

Taiwan, China |

|

7 |

Centralized lubrication |

BIJUR/HERG |

USA / Japan |

Note: The above is our standard supplier. It's subject to be replaced by same quality components of other brand if the above supplier can't supply the components in case of any special matter.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability