PHD2020C CNC Drilling Machine for Steel Plates

| Specification name | Items | Specification valve |

| Plate dimension | Material overlapping thickness | Max. 100mm |

| Width ×length | 2000mm×1600mm | |

| Spindle | Spindle boring | BT50 |

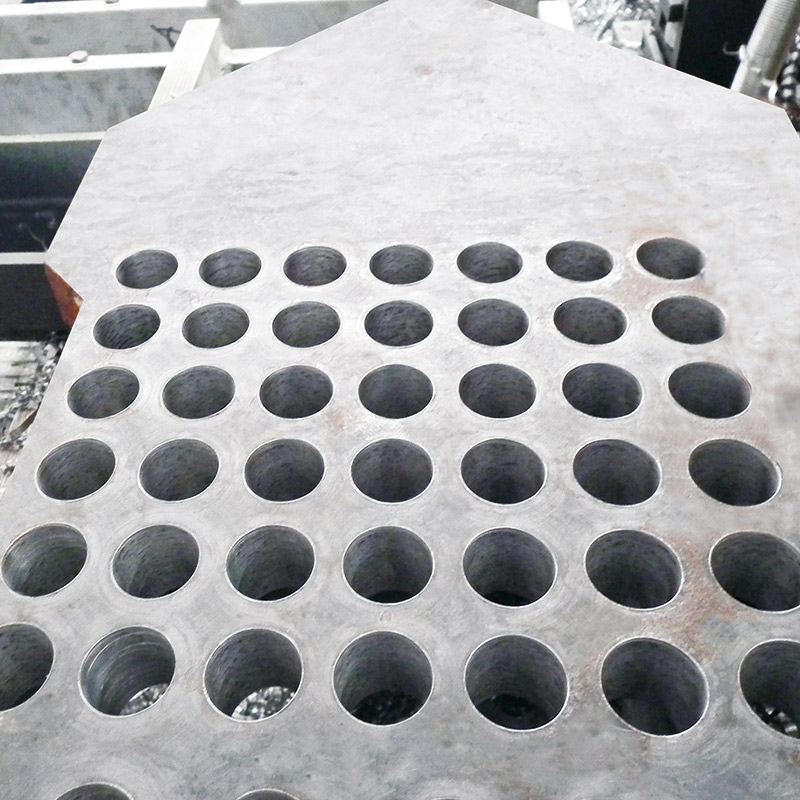

| Drill hole diameter | Ordinary twist drill maximum Φ50mm

Hard alloy drill maximum Φ40mm |

|

| Rotate speed(RPM) | 0-2000r/min | |

| Travel length | 350mm | |

| Spindle frequency conversion motor power | 15KW | |

| Plate clamp | Clamp thickness | 15-100mm |

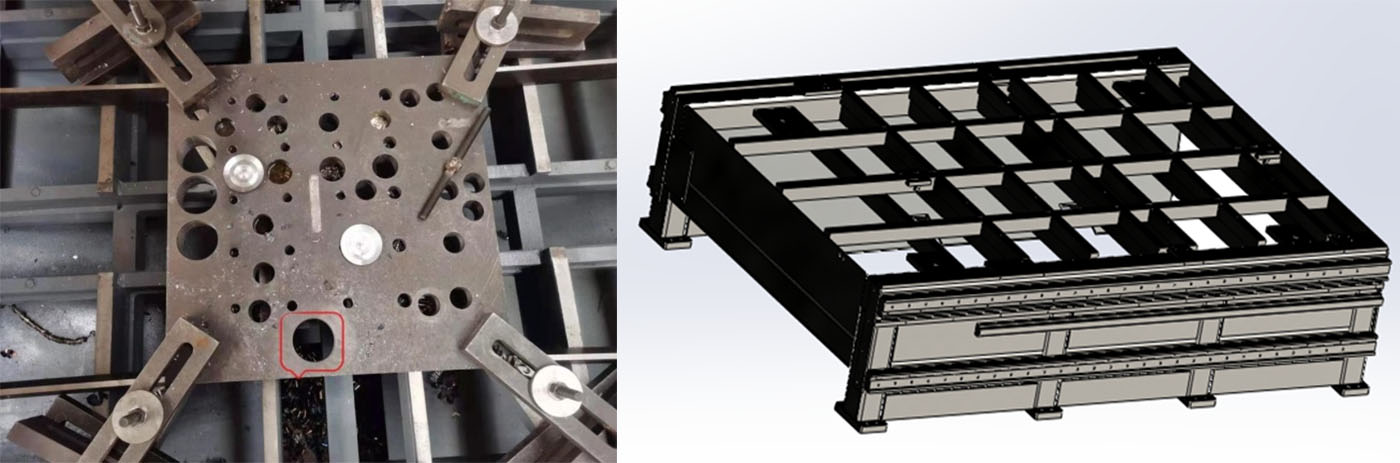

| clamp cylinder number | 12 | |

| Clamp force | 7.5kN | |

| Air pressure | Gas source demand | 0.8MPa |

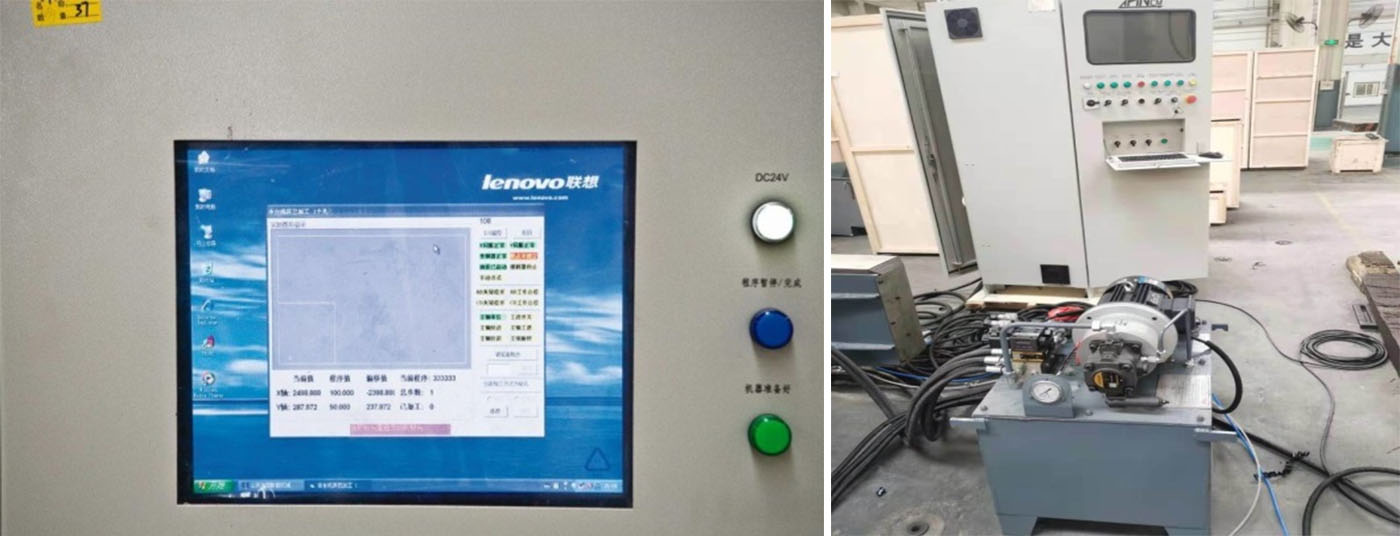

| Motor power | Hydraulic pump | 2.2kW |

| X axle servo system | 2.0kW | |

| Y axle servo system | 1.5kW | |

| Z axle servo system | 2.0 KW | |

| Chip conveyor | 0.75kW | |

| Travel range | X axle | 2000mm |

| Y axle | 1600mm |

1. The machine is mainly composed of bed (worktable), gantry, drilling head, hydraulic system, Electric control system, centralized lubrication system, cooling chip removal system etc.

2. It adopt precision spindle with high rotation accuracy and good rigidity.

3. This machine automatically processes the start and end points of the work entry through the host computer software. It can not only drill through holes but also blind holes, stepped holes, and hole end chamfers. It has high processing efficiency, high work reliability, simple structure and maintenance.

4. The machine adopts a centralized lubrication system instead of manual operation to ensure that the functional parts are well lubricated, improve the performance of the machine tool, and extend its service life.

5. The two methods of internal cooling and external cooling ensure the effect of cooling the drill head. The chips can be dumped into the dumpcart automatically.

6. The control system adopts the upper computer programming software which is independently developed by our company and matched with the programmable controller, which has a high degree of automation.

|

NO. |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

CSK/HIWIN |

Taiwan (China) |

|

2 |

Hydraulic pump |

Just Mark |

Taiwan (China) |

|

3 |

Electromagnetic hydraulic valve |

Atos/YUKEN |

Italy/Japan |

|

4 |

Servo motor |

Mitsubishi |

Japan |

|

5 |

Servo driver |

Mitsubishi |

Japan |

|

6 |

PLC |

Mitsubishi |

Japan |

|

7 |

Spindle |

Kenturn |

Taiwan, China |

|

8 |

Computer |

Lenovo |

China |

Note: The above is our standard supplier. It's subject to be replaced by same quality components of other brand if the above supplier can't supply the components in case of any special matter.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability