PD30B CNC Drilling Machine for Plates

| Item | Name | Value |

| Plate Size | Thickness | Maximum 80mm |

| Width x Length | 1600mm×3000mm (for One piece of plate) |

|

| 1500mm×1600mm ( for Two pieces of plate) |

||

| 800mm×1500mm (for Four pieces of plate) |

||

| Drilling bit Diameter | φ12-φ50mm | |

| Speed adjustment type | Frequency Inverter stepless speed change | |

| RPM | 120-560r/min | |

| Feeding | Hydraulic stepless speed adjustement | |

| Plate Clamping | Clamping thickness | Min. 15 ~ Max. 80mm |

| Clamping cylinder Nos. | 12 pieces | |

| Clamping force | 7.5KN | |

| Cooling | Method | Compulsory recycling |

| Motor | Spindle Motor | 5.5kW |

| Hydraulic Pump Motor | 2.2kW | |

| Scrap Removal Motor | 0.4kW | |

| Cooling Pump Motor | 0.25kW | |

| X Axis Servo Motor | 1.5kW | |

| Y Axis Servo Motor | 1.0kW | |

| Machine Size | L×W×H | About 5560×4272×2855mm |

| Weight | Main machine | About 8000 Kg |

| Travel | X Axis | 3000mm |

| Y Axis | 1600mm | |

| Maximum Positioning speed | 8000mm/min | |

1. Machine Frame, 1 set

2. Gantry, 1 set

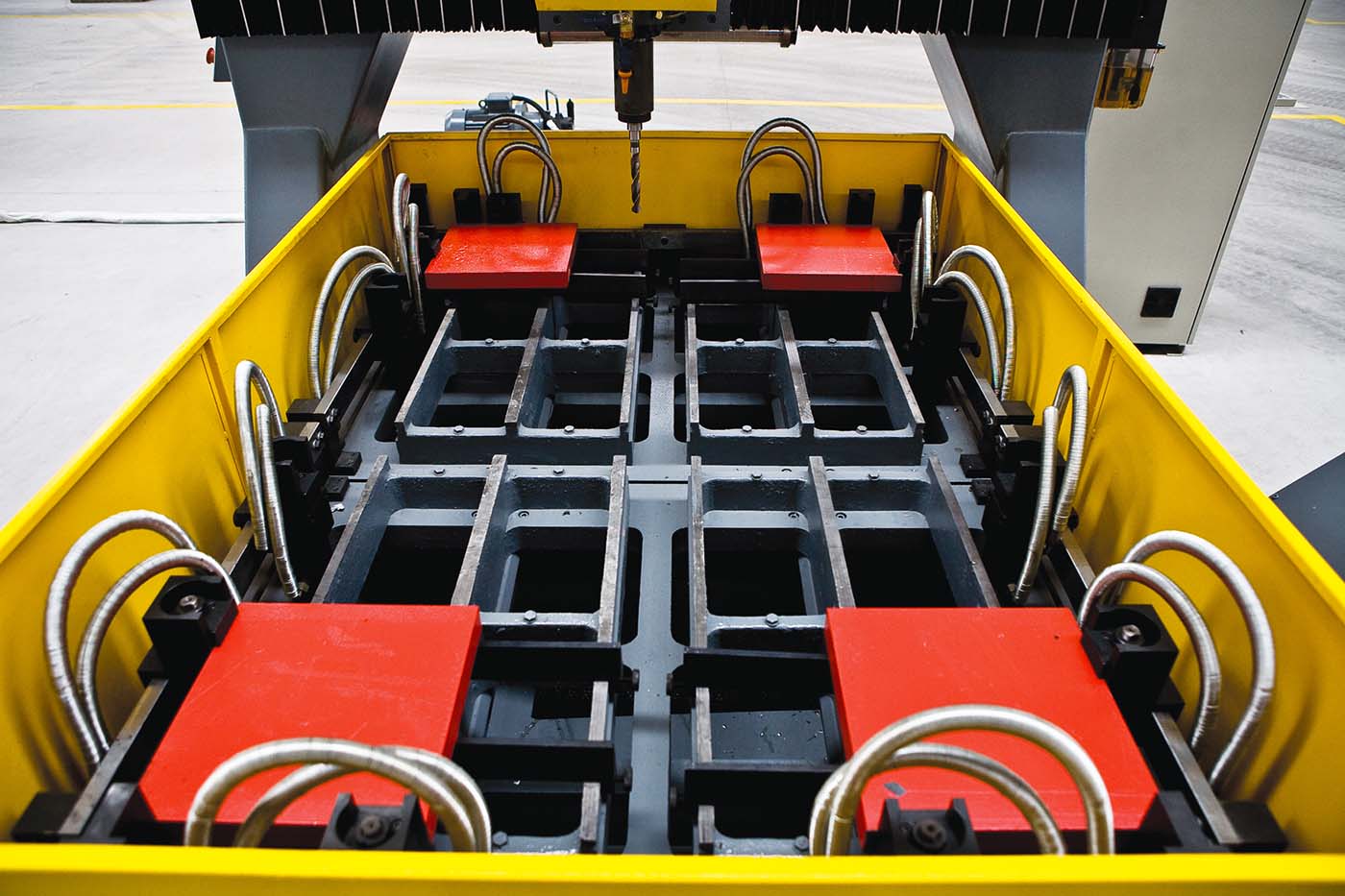

3. Position Exchangeable Worktable (Dual worktable), 1 set

4. Drilling Spindle, 1 set

5. Hydraulic System, 1 set

6. Electrical Control System, 1 set

7. Centralized Lubrication System, 1 set

8. Scrap Removal System, 1 set

9. Cooling System, 1 set

10. Quick change chuck of drilling tool, 1 set

1. Spindle Hydraulic automatic control stroke, which is our company’s patent technic know-how. It can automatically realize fast feeding- work feeding- fast return back, no need setting any parameters before operation.

2. Position Exchangeable Worktable (Dual worktable) One work table can continually working while the other work table in the progress of uploading/downloading the material, which can greatly save time and improve production efficiency.

3. Centralized Lubrication System Key components can be well lubricated, to secure the machine's good performance and long lifetime.

4. Cooling system There is coolant filter recycling-use device.

5. PLC control system The upper computer programming software is designed by FIN CNC company ourselves, it's very easy and convenient to operate, with automatic warning function.

|

No. |

Name |

Brand |

Country |

|

1 |

Linear guide rail |

CSK/HIWIN |

Taiwan (China) |

|

2 |

Hydraulic pump |

Just Mark |

Taiwan (China) |

|

3 |

Electromagnetic valve |

Atos/YUKEN |

Italy/Japan |

|

4 |

Servo motor |

Mitsubishi |

Japan |

|

5 |

Servo driver |

Mitsubishi |

Japan |

|

6 |

PLC |

Mitsubishi |

Japan |

|

7 |

Computer |

Lenovo |

China |

Note: The above is our standard supplier. It's subject to be replaced by same quality components of other brand if the above supplier can't supply the components in case of any special matter.

Company Brief Profile  Factory Information

Factory Information  Annual Production Capacity

Annual Production Capacity  Trade Ability

Trade Ability