BHD1206A/3 FINCM U Channel Steel Structure CNC High Speed Drilling Machine

3、There are three spindle boxes, which are respectively installed on three CNC sliding tables for horizontal and vertical drilling. Each spindle box can be drilled separately or at the same time.

4、The spindle adopts precision spindle with high rotation precision and good rigidity. Machine with BT40 taper hole, it is convenient for tool changing, and can be used to clamp twist drill and carbide drill.

5、The beam is fixed by hydraulic clamping. There are five hydraulic cylinders for horizontal clamping and vertical clamping respectively. The horizontal clamping is composed of fixed side reference and moving side clamping.

6、In order to meet the processing of multiple hole diameters, the machine is equipped with three in-line tool magazine, each unit is equipped with a tool magazine, and each tool magazine is equipped with four tool positions.

7、The machine is equipped with beam width detection and web height detection device, which can effectively compensate the deformation of the beam and ensure the machining accuracy; The two kinds of detection devices adopt the wire encoder, which is convenient to install and reliable to work.

8、The machine adopts the trolley feeding, and the CNC clamp feeding mechanism is composed of servo motor, gear, rack, detection encoder, etc.

9、Each spindle box equipped with its own external cooling nozzle and internal cooling joint, which can be selected according to the needs of drilling. Internal cooling and external cooling can be used separately or at the same time.

|

No. |

Item name |

Parameters |

|

|

1 |

H-beam |

Section height |

150~1250mm |

|

Flange width |

75~600mm |

||

|

2 |

U-shaped steel |

Section height |

150~1250mm |

|

Flange width |

75~300mm |

||

|

3 |

Workpiece length |

|

1500 ~15000mm |

|

4 |

Maximum thickness of workpiece |

|

75mm |

|

5 |

Drilling power box |

Quantity |

3 |

|

6 |

Maximum borehole diameter |

Cemented carbide¢ 30mm High-speed steel¢ 40mm |

|

|

Spindle taper hole |

BT40 |

||

|

Spindle motor power |

3*11KW |

||

|

Spindle speed (stepless speed regulation) |

20~2000r/min |

||

|

7 |

CNC axis |

Quantity |

6 |

|

Servo motor power of fixed side, moving side and middle side feed shaft |

3×2kW |

||

|

Fixed side, moving side, middle side, moving side positioning axis servo motor power |

3×1.5kW |

||

|

Moving speed of three positioning CNC axes |

0~10m/min |

||

|

Moving speed of three feed CNC axes |

0~5m/min |

||

|

Left and right horizontal distance of middle side |

40~760 mm |

||

|

Width detection stroke |

1100mm |

||

|

8 |

Web detection stroke |

290mm |

|

|

9 |

Feeding trolley |

Power of servo motor of feeding trolley |

5kW |

|

Maximum feeding speed |

20m/min |

||

|

Maximum feeding weight |

10t |

||

|

10 |

Cooling system |

Compressed air pressure required |

0.8Mpa |

|

Number of nozzles |

3 |

||

|

Cooling mode |

Internal cooling + external cooling |

||

|

11 |

Accuracy |

Error of adjacent hole spacing in hole group |

±0.4mm |

|

Accuracy error of 10m feeding |

±1.0 |

||

|

12 |

Overall dimensions of main engine (L x W x H) |

|

Aboutn 6.0*1.6*3.4 m |

|

13 |

Main engine weight |

|

About 8000kg |

1、The drilling machine is mainly composed of bed, CNC sliding table (3), drilling spindle (3), clamping device, detection device, cooling system, scrap iron box, etc.

2、There are three CNC sliding tables, which are fixed side CNC sliding table, mobile side CNC sliding table and middle CNC sliding table. The three sliding tables are composed of sliding plate, sliding table and servo drive system. There are six CNC axis on the three sliding tables, including three feed CNC axes and three positioning CNC axes. Each CNC axis is guided by precision linear rolling guide and driven by AC servo motor and ball screw, which ensures its positioning accuracy.

|

No. |

Name |

Brand |

Country |

|

1 |

Principal axis |

Keturn |

Taiwan, China |

|

2 |

Linear rolling guide pair |

HIWIN/CSK |

Taiwan, China |

|

3 |

Hydraulic pump |

JUSTMARK |

Taiwan, China |

|

4 |

Electromagnetic hydraulic valve |

ATOS/YUKEN |

Italy / Japan |

|

5 |

Servo motor |

Siemens / MITSUBISHI |

Germany / Japan |

|

6 |

Servo driver |

Siemens / MITSUBISHI |

Germany / Japan |

|

7 |

Programmable controller |

Siemens / MITSUBISHI |

Germany / Japan |

|

8 |

computer |

Lenovo |

China |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

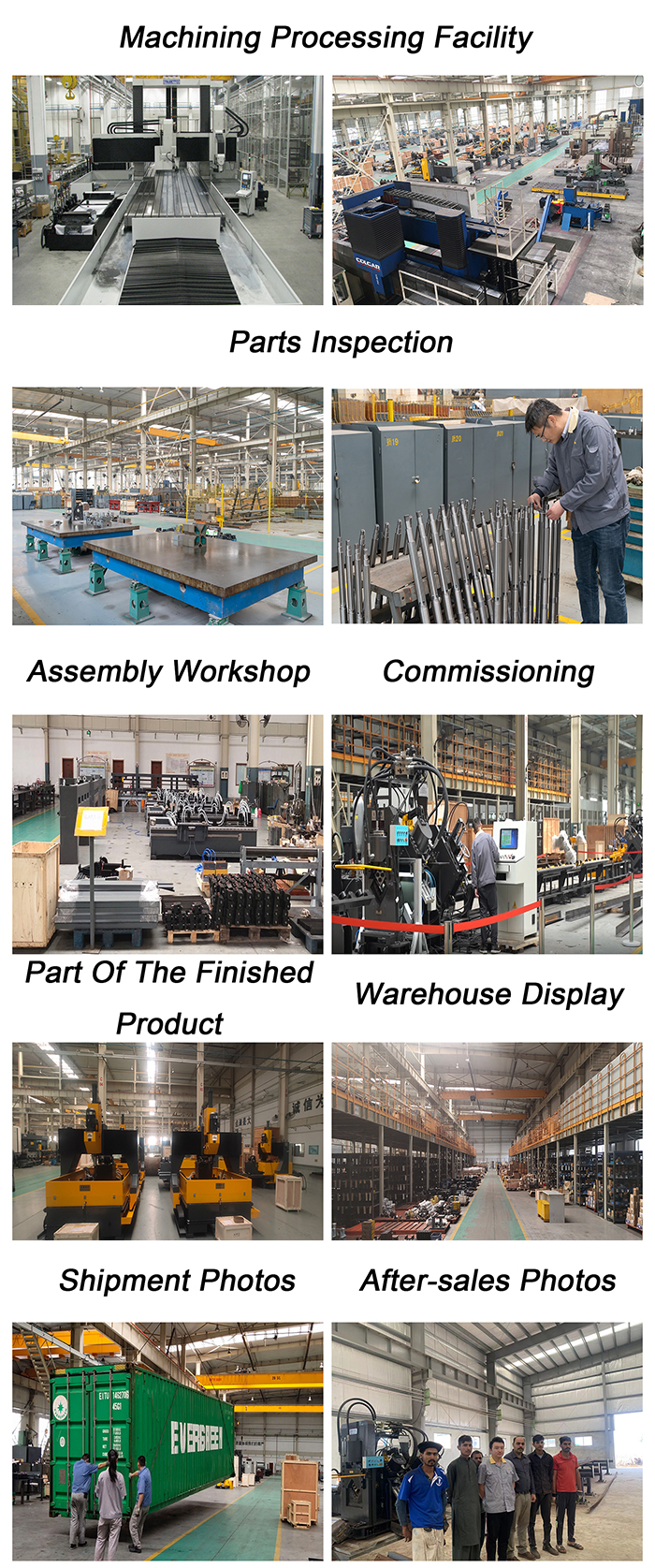

Our company makes CNC machines for processing various steel profiles material, such as Angle bar profiles, H beams/U channels and steel plates.

|

Business Type |

Manufacturer, Trading Company |

Country / Region |

Shandong, China |

|

Main Products |

Ownership |

Private Owner |

|

|

Total Employees |

201 – 300 People |

Total Annual Revenue |

Confidential |

|

Year Established |

1998 |

Certifications(2) |

|

|

Product Certifications |

- |

Patents(4) |

|

|

Trademarks(1) |

Main Markets |

|

|

Factory Size |

50,000-100,000 square meters |

|

Factory Country/Region |

No.2222, Century Avenue, High-tech Development Zone, Jinan City, Shandong Province, China |

|

No. of Production Lines |

7 |

|

Contract Manufacturing |

OEM Service Offered, Design Service Offered, Buyer Label Offered |

|

Annual Output Value |

US$10 Million – US$50 Million |

|

Product Name |

Production Line Capacity |

Actual Units Produced(Previous Year) |

|

CNC Angle Line |

400 Sets/Year |

400 Sets |

|

CNC Beam Drilling Sawing Machine |

270 Sets/Year |

270 Sets |

|

CNC Plate Drilling Machine |

350 Sets/Year |

350 Sets |

|

CNC Plate Punching Machine |

350 Sets/Year |

350 Sets |

|

Language Spoken |

English |

|

No. of Employees in Trade Department |

6-10 People |

|

Average Lead Time |

90 |

|

Export License Registration NO |

04640822 |

|

Total Annual Revenue |

confidential |

|

Total Export Revenue |

confidential |